Polyline intersecting line cutting device for round pipe end

An intersecting line cutting, multi-line segment technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding/welding/cutting items, etc., can solve the problems of inconvenient transportation, high cost, poor overall quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings, wherein, the orientation words in the present invention are up, down, front, back, left, and right. figure 1 as the benchmark.

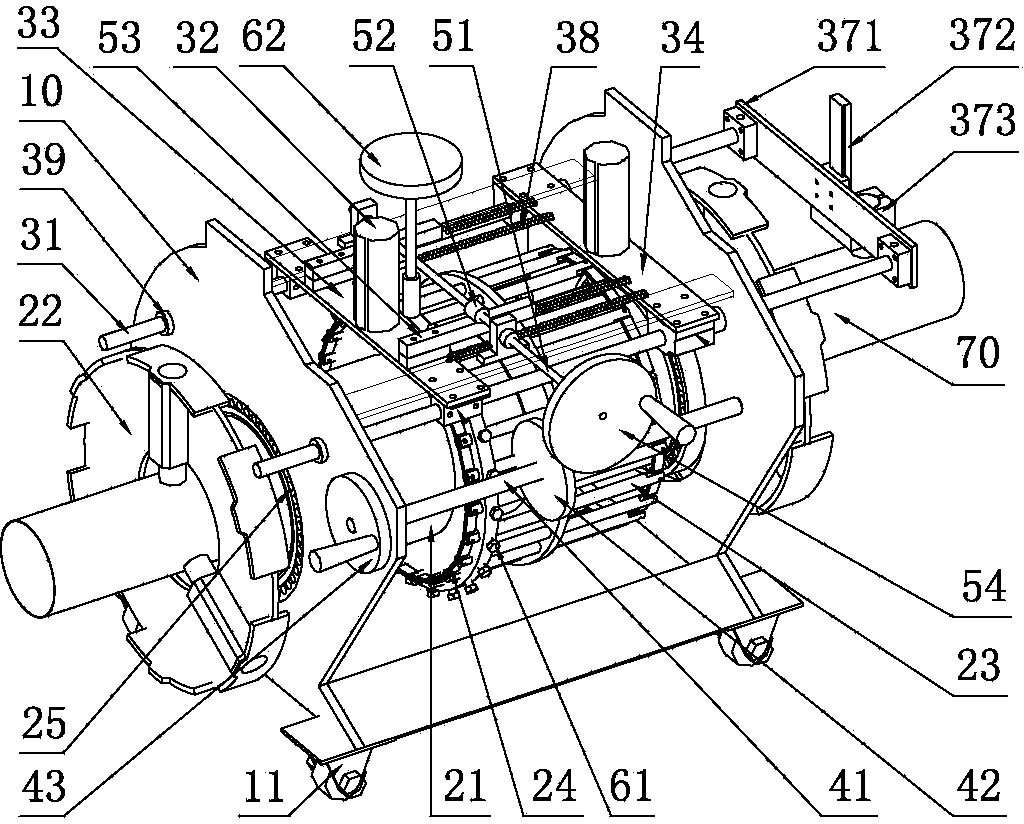

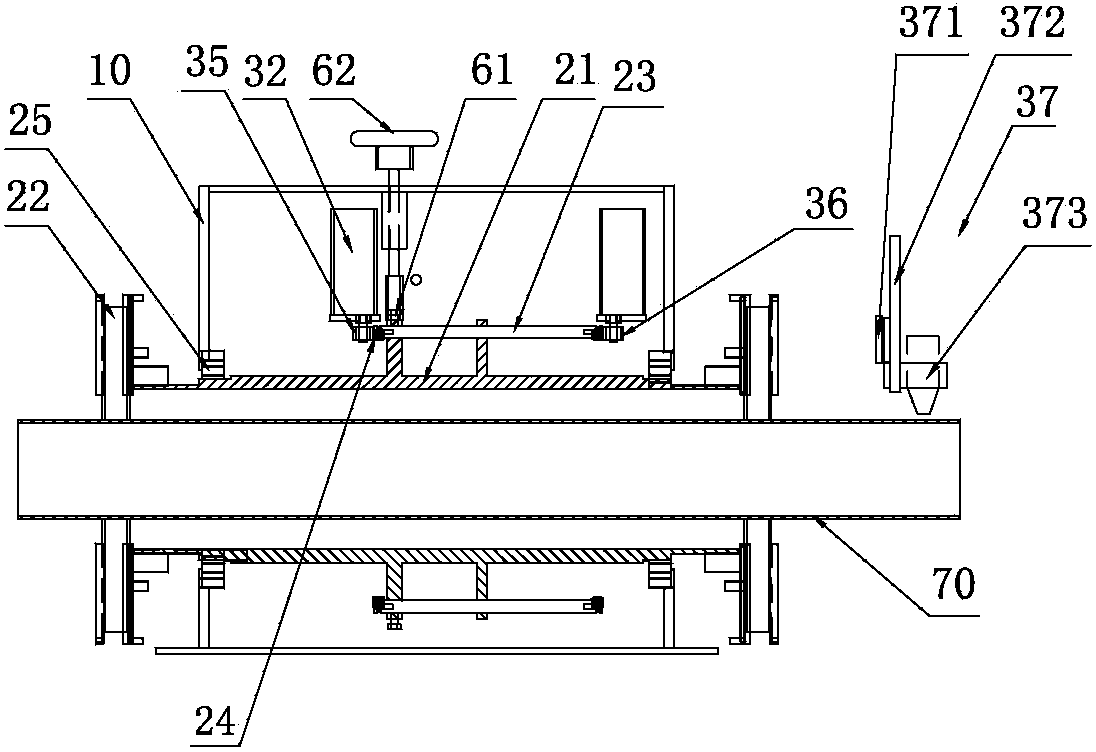

[0042] Such as Figure 1 to Figure 6 As shown, the multi-line segment intersecting line cutting device at the end of the circular pipe of the present invention includes a bracket 10, a circular rotation mechanism and a linear sliding mechanism;

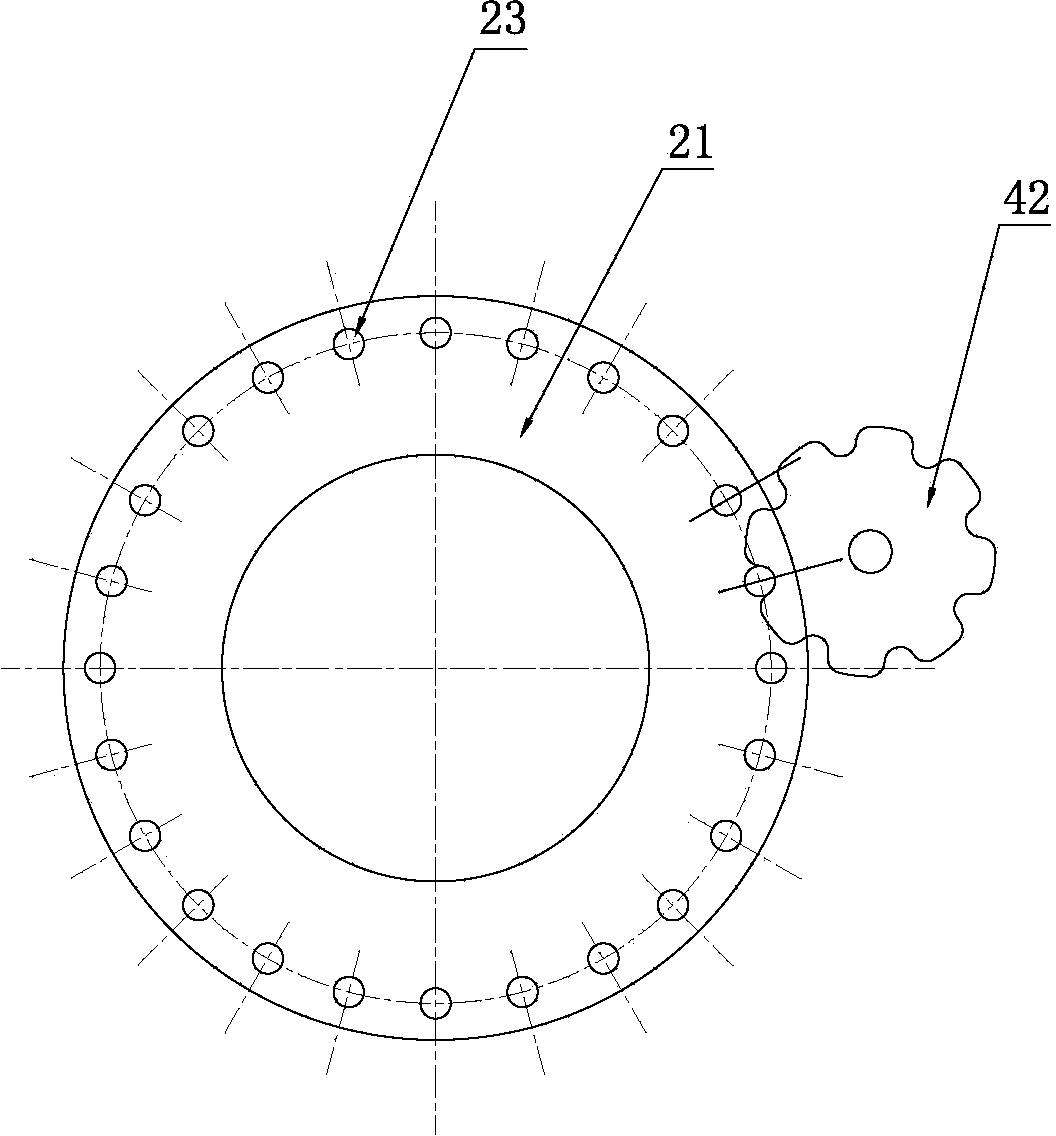

[0043] The circular rotation mechanism includes a central flange cylinder shaft 21, a circular pipe clamp 22, and several plain wire shafts 23; the central flange cylinder shaft 21 is arranged in the bracket 10, and the circular pipe clamp 22 is arranged on the central flange cylinder shaft 21 At the end, several plain thread shafts 23 are annularly arranged on the outside of the central flange cylinder shaft 21, and the two ends between adjacent plain thread shafts 23 are connected with transition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com