Betel nut slicer

A technology of slicer and betel nut, applied in metal processing and other directions, can solve the problems of high work intensity, fatigue of production personnel, low production efficiency, etc., and achieve the effect of reducing work intensity, avoiding direct contact and enhancing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, invention is described in further detail.

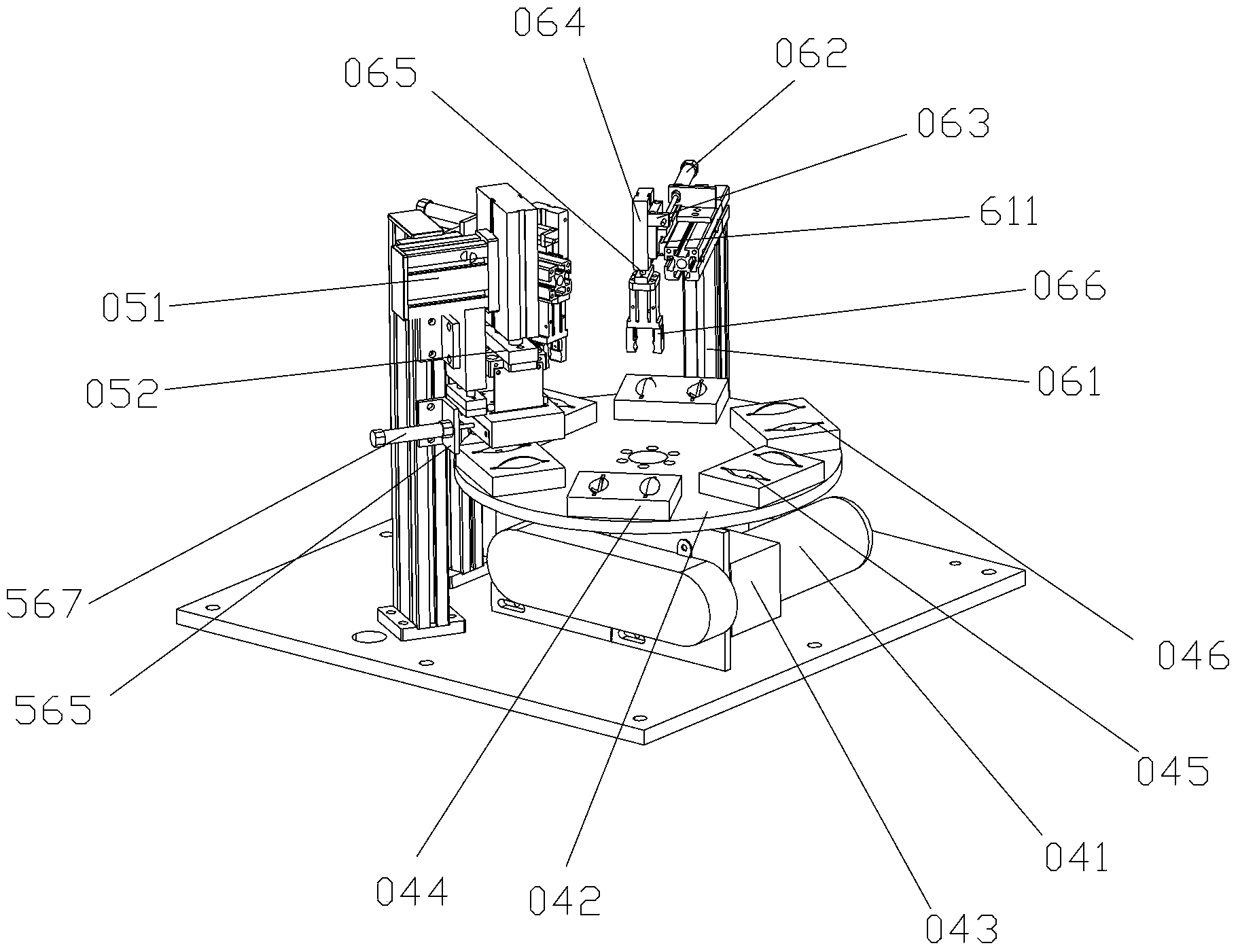

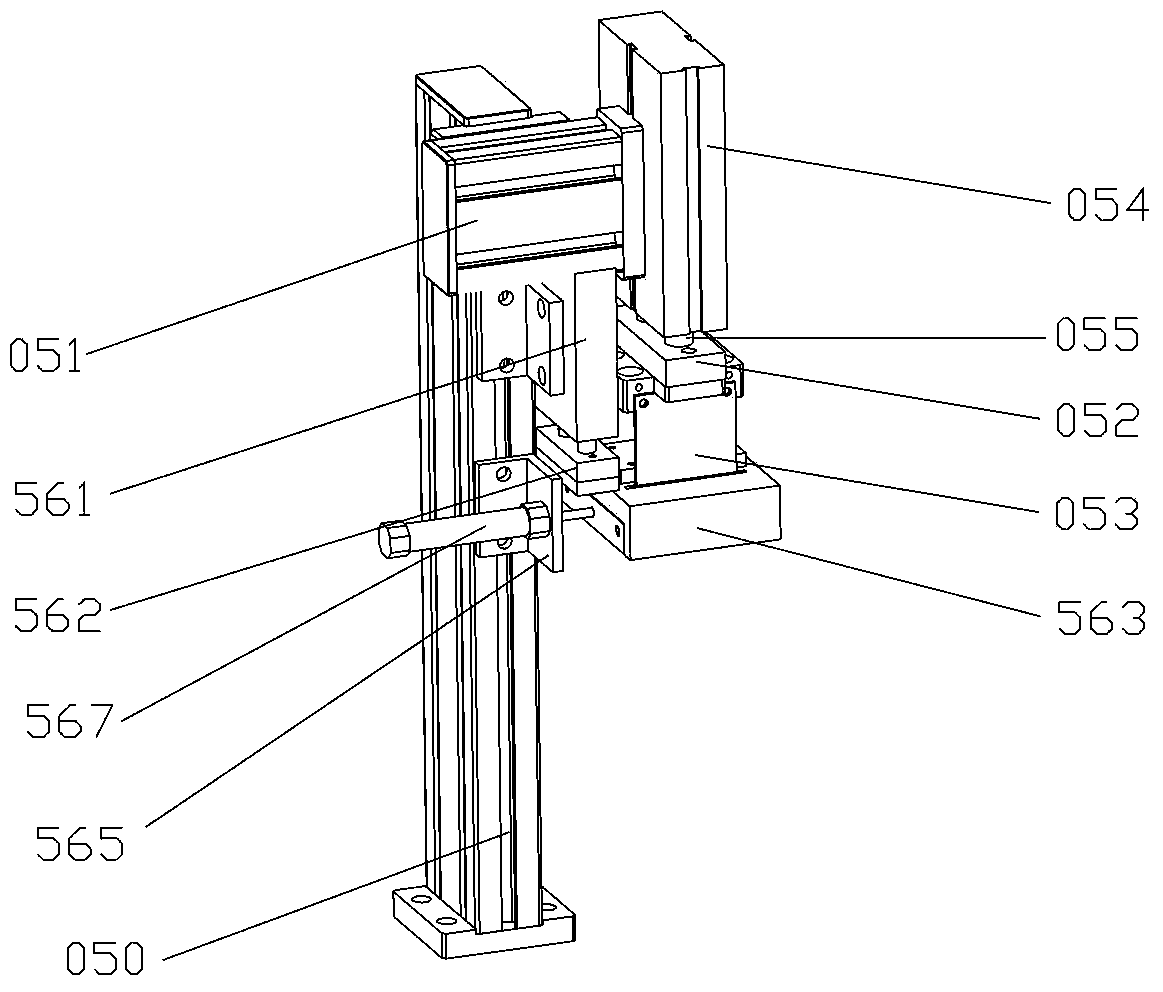

[0021] Figure 1 to Figure 5 A betel nut slicer according to the invention is schematically shown.

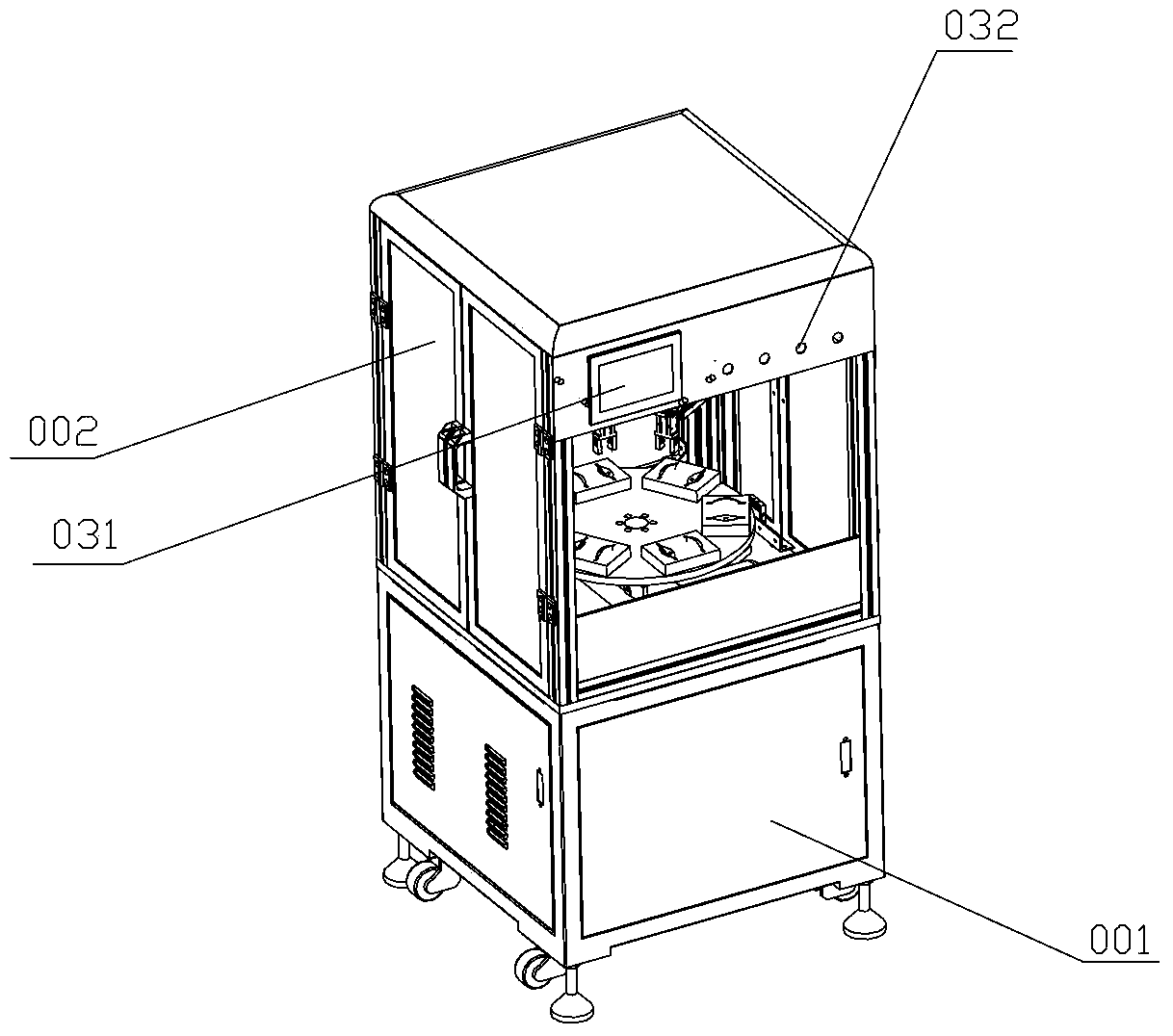

[0022] According to an aspect of the invention, a kind of betel nut slicer is provided, including a base 001, a top shell 002, a control device, a manipulator, a feeding mechanism and a cutting device, as follows:

[0023] The machine base 001 is provided with a discharge port and a top for installing related components. In this embodiment, it also includes a discharge channel and a collection box. The collection box is installed inside the machine base 001 and is connected to the discharge port through the discharge channel. .

[0024] The control device includes a man-machine interface 031, a PLC controller and a control switch 032, and the man-machine interface 031 and the control switch 032 are all connected to the PLC controller.

[0025] The feeding mechanism is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com