Fully automatic framed painting assembly line

A production line, fully automatic technology, applied in the direction of picture frames, decorative arts, special decorative structures, etc., can solve the problems of harmful human health, high labor costs, slow process speed, etc., to reduce the scrap rate, beautiful finished products, convenient and error-free The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

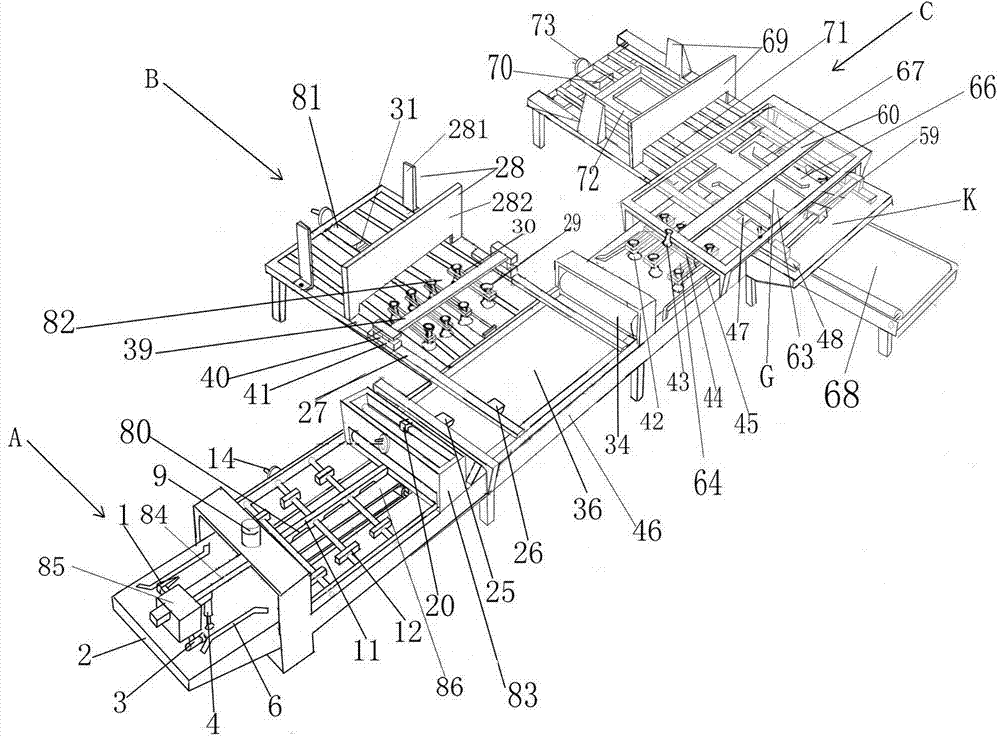

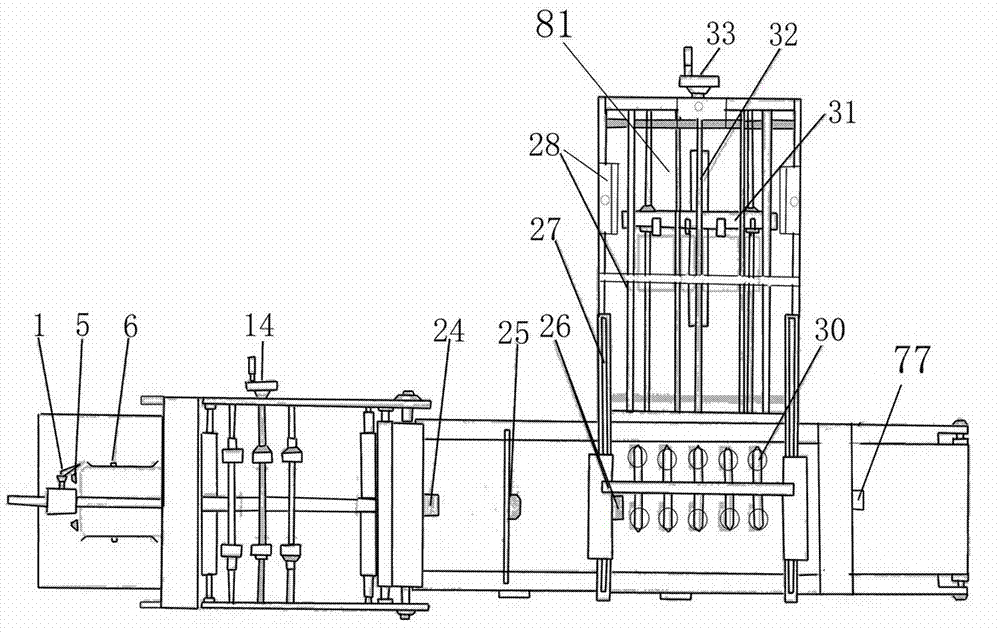

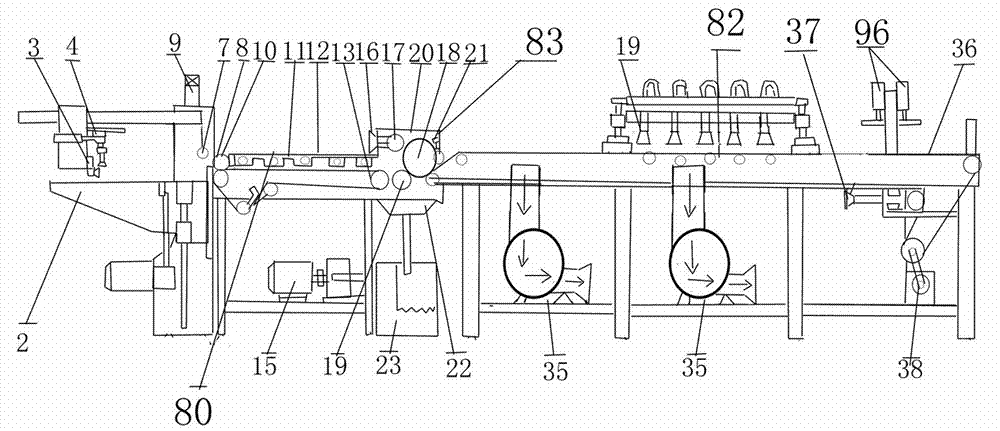

[0022] see figure 1 , figure 2 and image 3 As shown, it is an embodiment of the present invention, which is composed of a gluing device A, a drawing board positioning device B and a picture frame assembly device C, and the described gluing device A, drawing board positioning device B and picture frame assembly device C are all arranged on the machine On the frame 46, the gluing device A is arranged on the front portion of the frame 46, the drawing board positioning device B is arranged on the middle part of the frame 46, and the picture frame assembly device C is arranged on the rear portion of the frame 46;

[0023] Described gluing device A comprises picture stacking platform 2, walking painting platform 80 and gluing mechanism 83, and picture stacking platform 2 top is provided with fixed mount 84, and fixed mount 84 is provided with feeder 85, and feeder 85 is provided with The first vertical cylinder, the bottom of the first vertical cylinder is connected with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com