Automobile vibration attenuation seat

A technology for car seats and support seats, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of poor air permeability of foam plastic blocks, small spring damping, poor buffering effect, etc., and achieve excellent vibration isolation performance. , Solid support, the effect of reducing the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

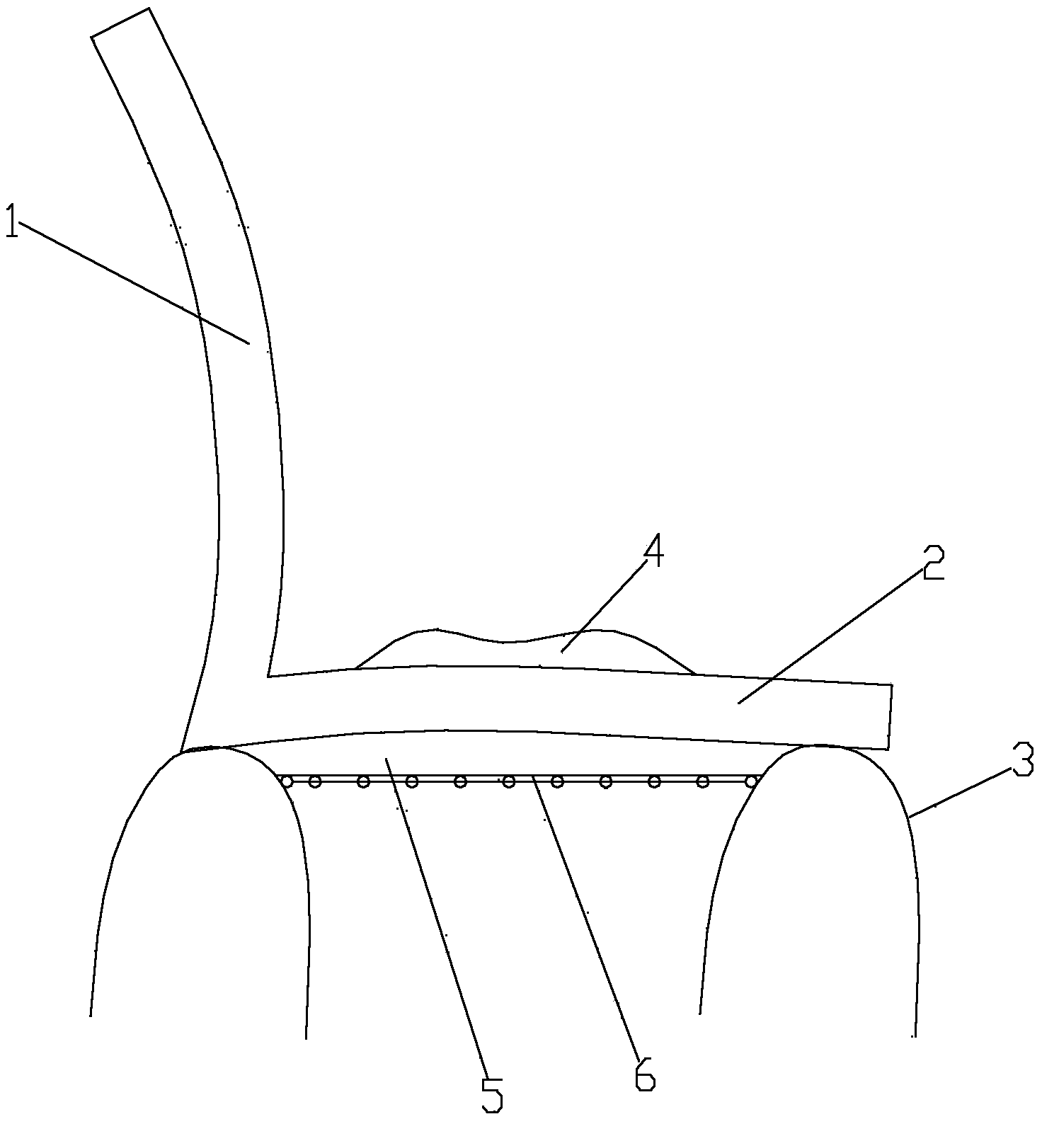

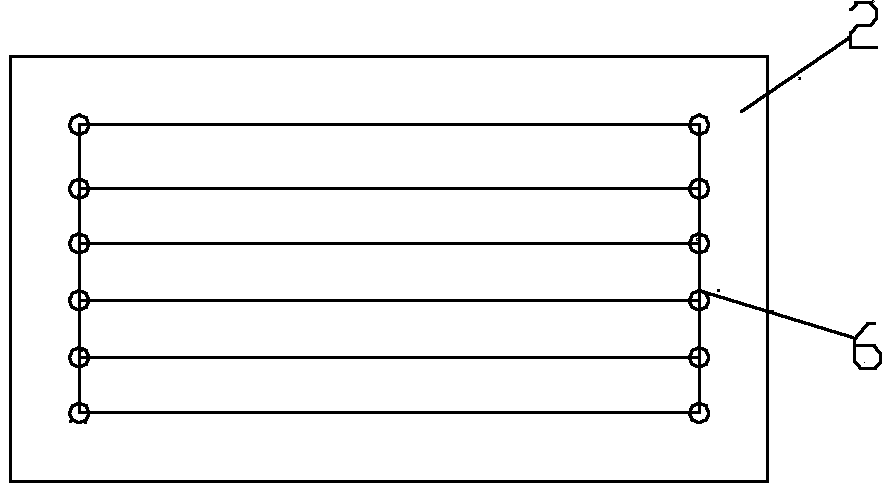

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 , 2 It is a kind of shock-absorbing car seat according to the present invention, comprising a backrest 1, a cushion 2 connected to the lower end of the backrest 1, and a support seat 3 for supporting the cushion 3, the backrest 1 and the cushion 2 are made of The sponge with elastic properties is filled into the cortical layer, and a high-density sponge insert 4 is provided in the upper middle of the seat cushion 2; a shockproof pad 5 is provided below the seat cushion 2; an elastic component 6 is provided below the shockproof pad 5 The elastic component 6 is composed of a plurality of springs enclosing a net frame structure; the net frame structure is a closed rectangular frame composed of spring steel wires and a plurality of spring steel wires arranged in the rectangular frame at equal intervals.

[0014] A high-density sponge insert 4 is added to the part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com