Process for manufacturing bulbous bow in left-right split manner then in combined manner

A manufacturing process and bulbous bow technology, which is applied in the field of bulbous bow manufacturing process of left and right separation and recombination, can solve the problems of low work efficiency, high construction cost, and high labor intensity of construction personnel, so as to reduce labor intensity , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with reference to the accompanying drawings:

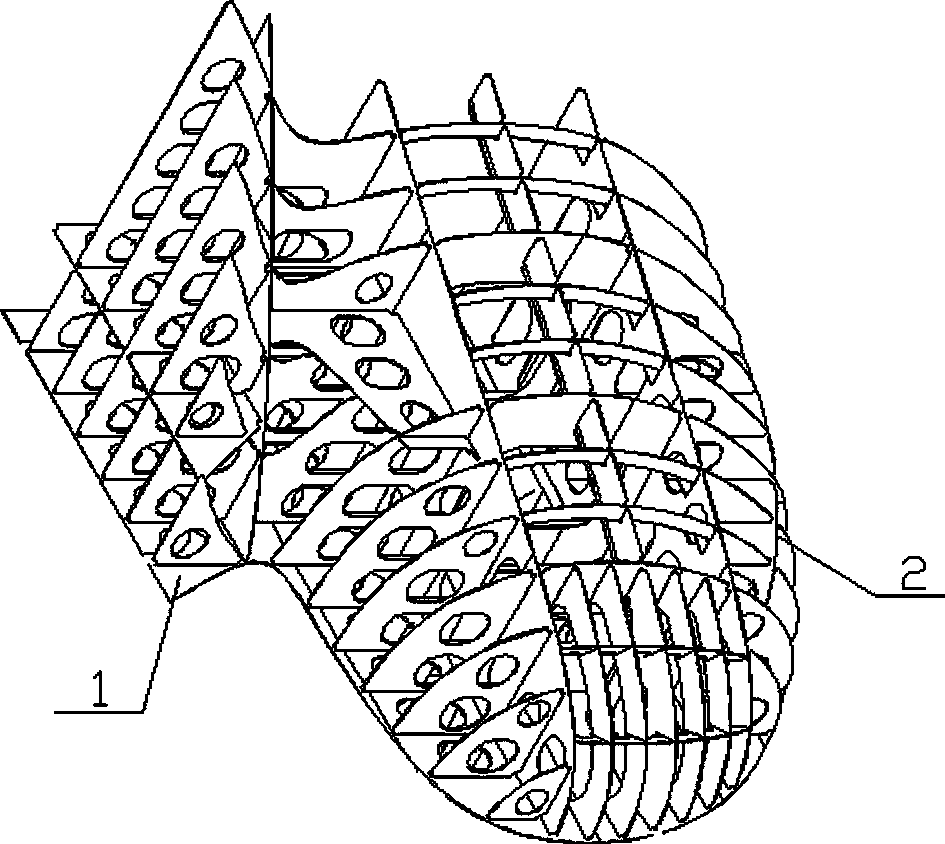

[0041] refer to Figure 1-15 , a bulbous bow manufacturing process that is separated from the left and right and then combined, including the production of the left part, the production of the right part, and the overall production of the bulbous bow. The left part and the right part are carried out with the most aft bulkhead as the reference plate Combined system to form a complete bulbous bow, the specific process is as follows:

[0042] (1) Production of the left part:

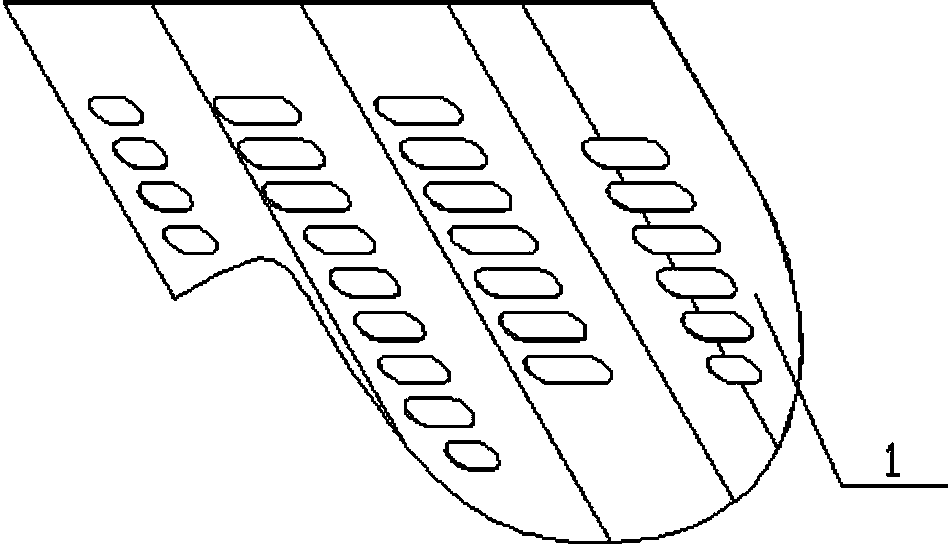

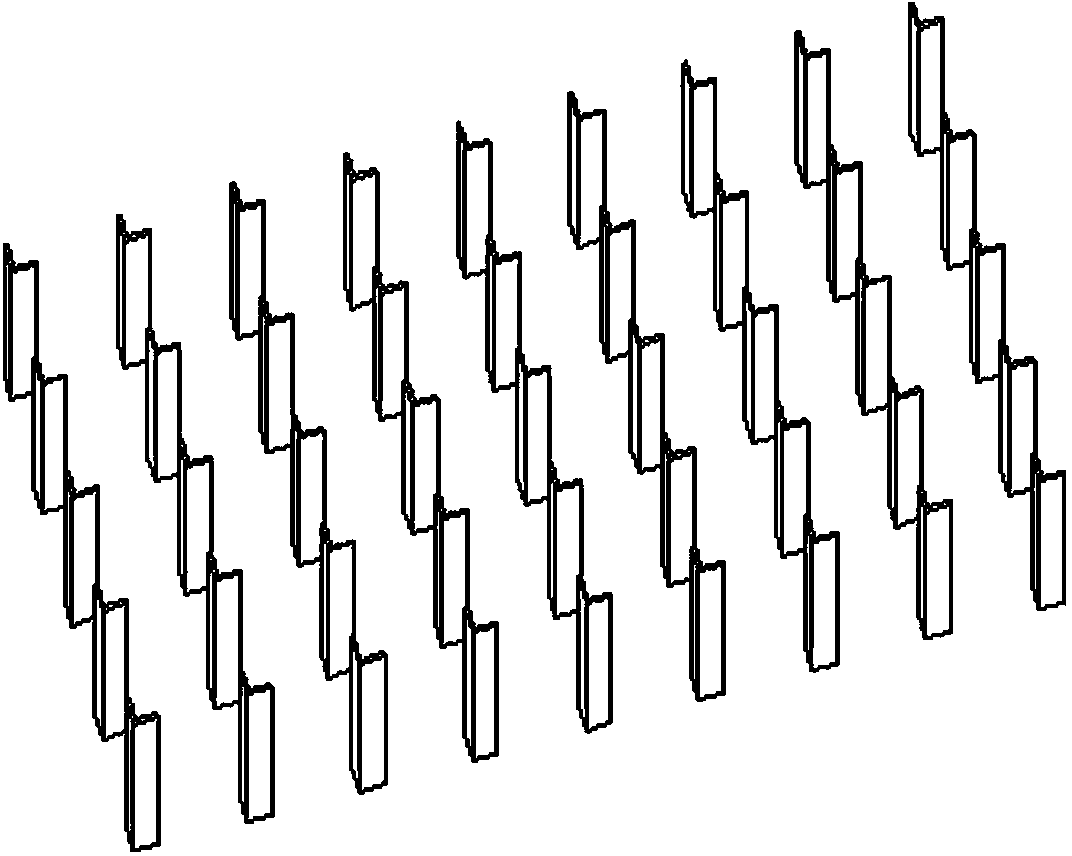

[0043] will be as figure 1 The middle vertical wall panel 1 shown is hung up as figure 2 For the positioning of the horizontal platform frame shown, the levelness of the middle longitudinal wall plate and the levelness accuracy error of the horizontal platform frame are all controlled within ±2mm;

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com