Preparation method and application of silica sol with irregular shape

An irregular, silica sol technology, which is applied in the polishing of sapphire and hard disks, and in the field of silicon wafers, can solve the problems of inapplicability of chemical mechanical polishing and lack of explanation of the use effect of chemical mechanical polishing, and achieve good colloidal stability, high polishing rate, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 prepares silica sol with irregular shape

[0013] Weigh 500g of 10nm small particle size spherical silica sol with a concentration of 2% as the mother liquor, and add it to the three-necked bottle

[0014] Then add 10g of 30% sodium carbonate solution to the mother liquor, stir evenly, and then adjust its pH value to 9-10 with 5% sodium hydroxide aqueous solution. Stir and heat to boiling, drop active silicic acid into the reaction system at a flow rate of 5ml / min, the total amount of silicic acid added dropwise is 2500g of the mother liquor, during which 5% sodium hydroxide aqueous solution is added dropwise to maintain the pH value of the reaction system In the range of 9-10, the dropwise addition was completed and the reaction product was cooled to room temperature.

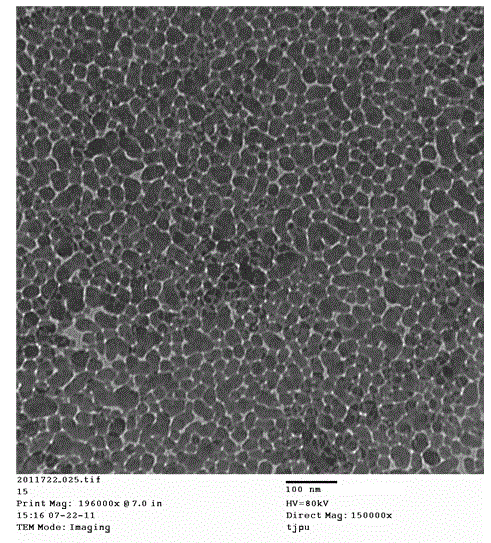

[0015] according to figure 1 It can be seen from the figure that the silica sol particles in the irregular silica sol have irregular morphology and basically no spherical particles.

Embodiment 2

[0016] Embodiment 2 prepares silica sol with irregular shape

[0017] Weigh 500g of 10nm small particle size spherical silica sol with a concentration of 3.5% as the mother liquor, add it into a three-necked bottle, then add 5g of 25% sodium sulfate solution to the mother liquor, stir evenly, and then adjust its pH with 5% sodium hydroxide aqueous solution Value to 9-10. Stir and heat to boiling, drop active silicic acid into the reaction system at a flow rate of 4ml / min, the total amount of silicic acid added dropwise is 3500g, during which 5% sodium hydroxide aqueous solution is added dropwise to keep the pH value of the reaction system at 9 In the range of -10, the dropwise addition was completed and the reaction product was cooled to room temperature.

[0018] according to figure 1 It can be seen from the figure that the silica sol particles in the irregular silica sol have irregular morphology and basically no spherical particles.

Embodiment 3

[0019] Embodiment 3 prepares silica sol with irregular shape

[0020] Take by weighing 500g of 15nm small particle size spherical silica sol with a concentration of 2.5% as the mother liquor, add it into a three-neck bottle, then add 1000ppm trivalent aluminum ion solution to the mother liquor, stir evenly, and then adjust its concentration with 10% aqueous sodium hydroxide solution. pH to 9-10. Stir and heat to boiling, drop active silicic acid into the reaction system at a flow rate of 5ml / min, the total amount of silicic acid added dropwise is 5000g, during which 10% sodium hydroxide aqueous solution is added dropwise to keep the pH value of the reaction system at 9 In the range of -10, the dropwise addition was completed and the reaction product was cooled to room temperature.

[0021] according to figure 1 It can be seen from the figure that the silica sol particles in the irregular silica sol have irregular morphology and basically no spherical particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com