Preparation method of composite cerium-zirconium oxide polishing powder

A composite oxide and polishing powder technology, which is applied in the direction of chemical instruments and methods, and other chemical processes, to achieve the effects of small particle size, significant synergistic polishing, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

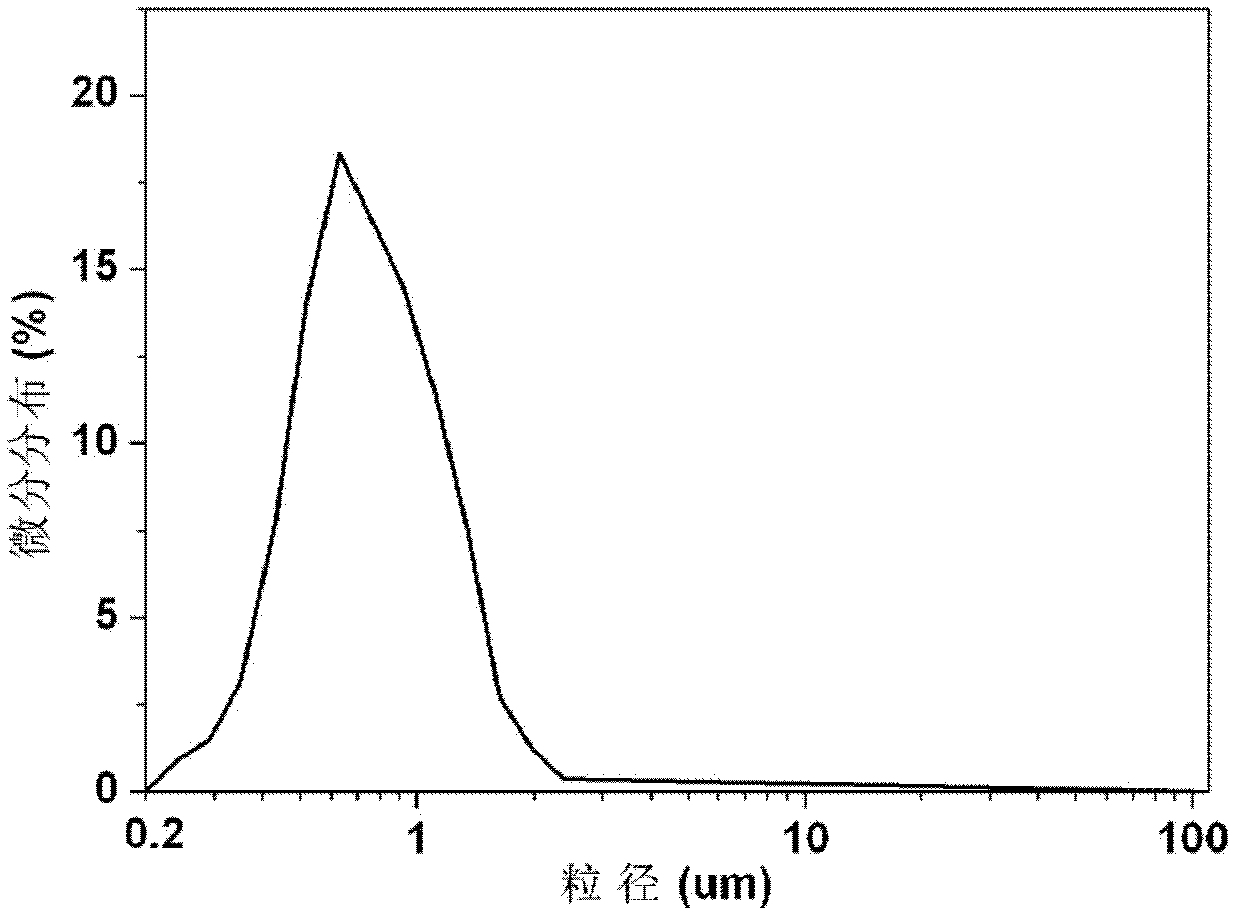

[0023] (1) Ball mill pulverization: weigh 260 g of cerium carbonate (Ce 2 (CO 3 ) 3 ·8H 2 O) As a cerium source, add 2340 g of deionized water, stir and disperse, and prepare a slurry with a solid content of 10 wt% for high-energy ball milling and pulverization, until the average particle size of the particles in the corresponding slurry is D. 50 Equal to 0.66μm, D 90 equal to 1.16μm (eg figure 1 shown);

[0024] (2) Precipitation mixing: 373.2 g of zirconium nitrate (Zr(NO) was added to the product of step (1). 3 ) 4 ·5H 2 O), stir to prepare a mixed slurry of Ce:Zr=5:5 (molar ratio), slowly add ammonium bicarbonate solution (concentration of 10wt%) to the mixed slurry to precipitate zirconium ions, when the pH of the mixed solution reaches about 7.0 When the precipitation is over, continue to stir the mixed solution for 1 hour, then let it stand for 3 hours, and then dry at 80°C for 6 hours after dehydration;

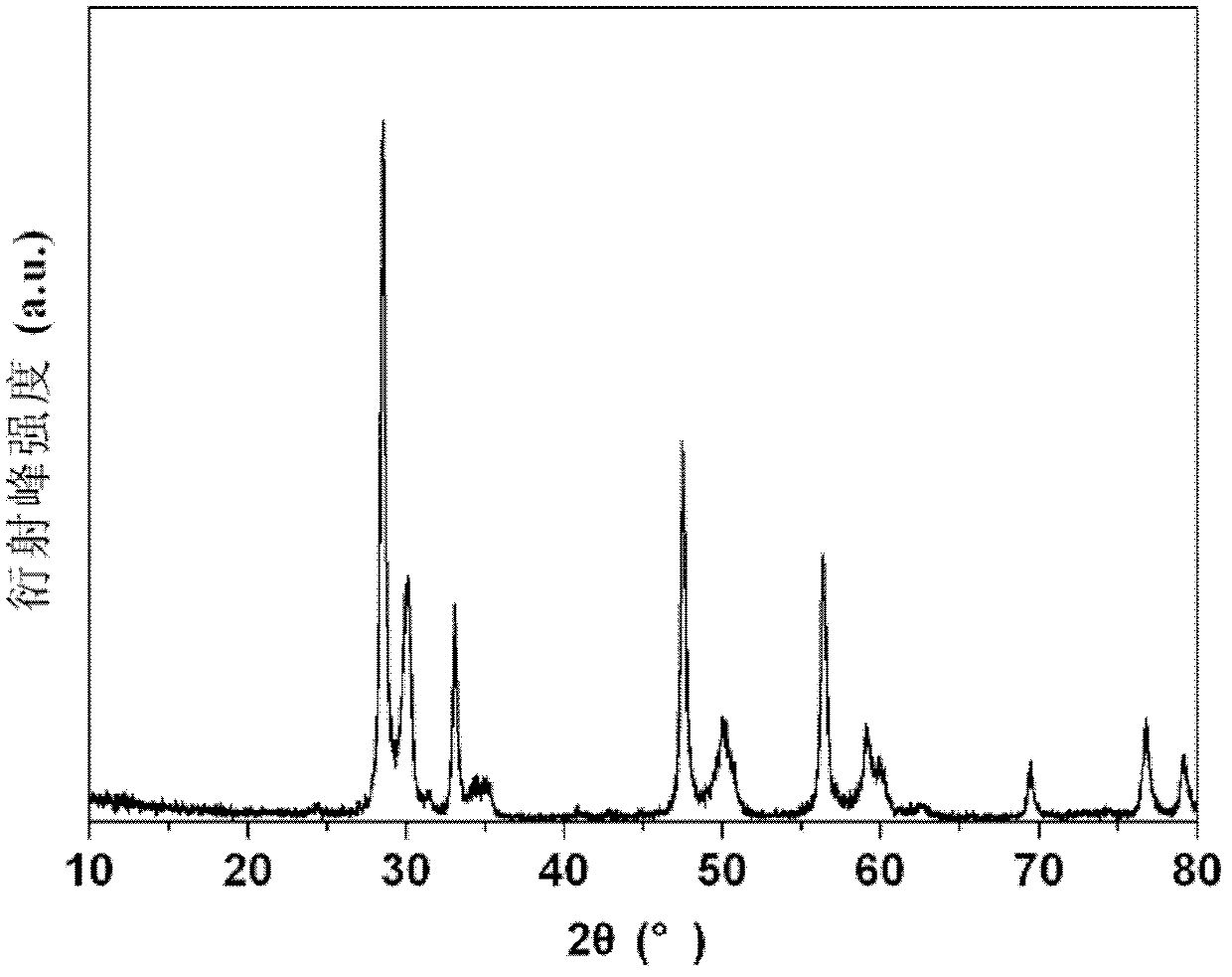

[0025] (3) calcination: the product of step (2) is calc...

Embodiment 2

[0028] (1) Ball mill pulverization: Weigh 200 g of cerium hydroxide as a cerium source (corresponding to CeO 2 content is 80wt%), add 3800g deionized water, stir and disperse, prepare a slurry with a solid content of about 5wt%, and conduct high-energy ball milling and pulverize until the average particle size of the particles in the corresponding slurry is D. 50 is 0.7 μm, D 90 is 1.2μm;

[0029] (2) Precipitation mixing: 99.8 g of zirconium nitrate (Zr(NO) was added to the product of step (1). 3 ) 4 ·5H 2 O), stir to prepare a mixed slurry of Ce:Zr=8:2 (molar ratio), slowly add ammonia water (concentration: 30wt%) to the mixed slurry to precipitate zirconium ions, when the pH of the mixed solution reaches about 10.0, the precipitation After the end, continue to stir the mixed solution for 2 hours, then stand for 5 hours, and then dry at 80°C for 12 hours after dehydration;

[0030] (3) calcination: the product of step (2) is calcined at 1000° C. for 3 hours to obtain a ...

Embodiment 3

[0033] (1) Ball mill pulverization: Weigh 200 g of cerium oxalate as a cerium source (Ce (C 2 O 4 ) 3 ·9H 2 O), add 1800g deionized water, stir and disperse, prepare a slurry with a solid content of 10wt% and carry out high-energy ball milling pulverization, until the average particle size D of the corresponding slurry 50 is 0.72 μm, D 90 is 1.33 μm;

[0034] (2) Precipitation mixing: add 730 g of zirconium oxychloride (ZrOCl) to the product of step (1) 2 ·8H 2 O), stir to prepare a mixed slurry of Ce: Zr=2: 8 (molar ratio), and slowly add oxalic acid solution (concentration of 20wt%) to the mixed slurry while stirring to precipitate zirconium ions. Add oxalic acid dropwise to the supernatant, no more precipitation will be produced, the precipitation is over (the pH value is about 2.0), continue to stir the mixed solution for 2 hours, then let stand for 5 hours, and dry at 80 ° C for 10 hours after dehydration;

[0035] (3) calcination: the product of step (2) is calcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com