Multipurpose polishing solution main solution

A polishing liquid, multi-purpose technology, applied in polishing compositions containing abrasives, etc., can solve the problem of a single use range of the same polishing liquid, and achieve the effects of good flatness, good suspension, and fast polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

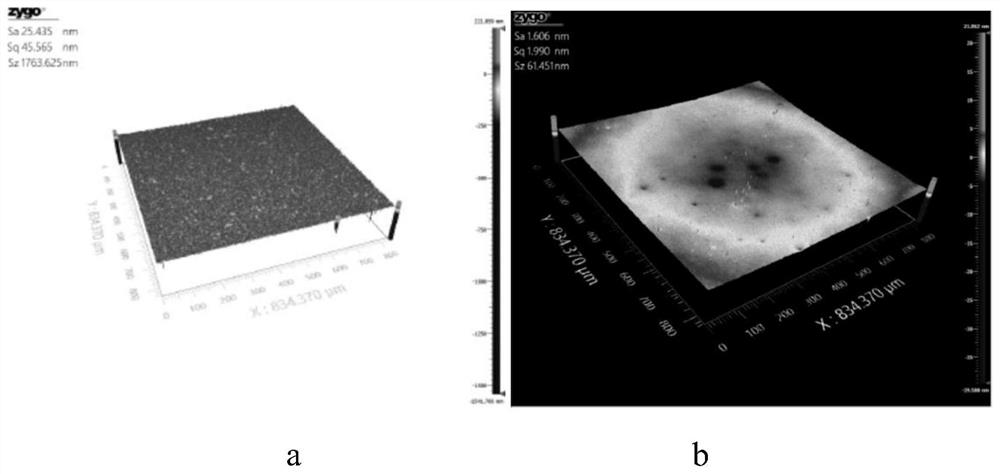

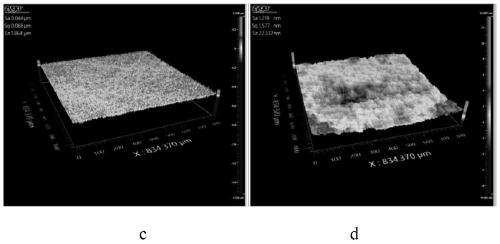

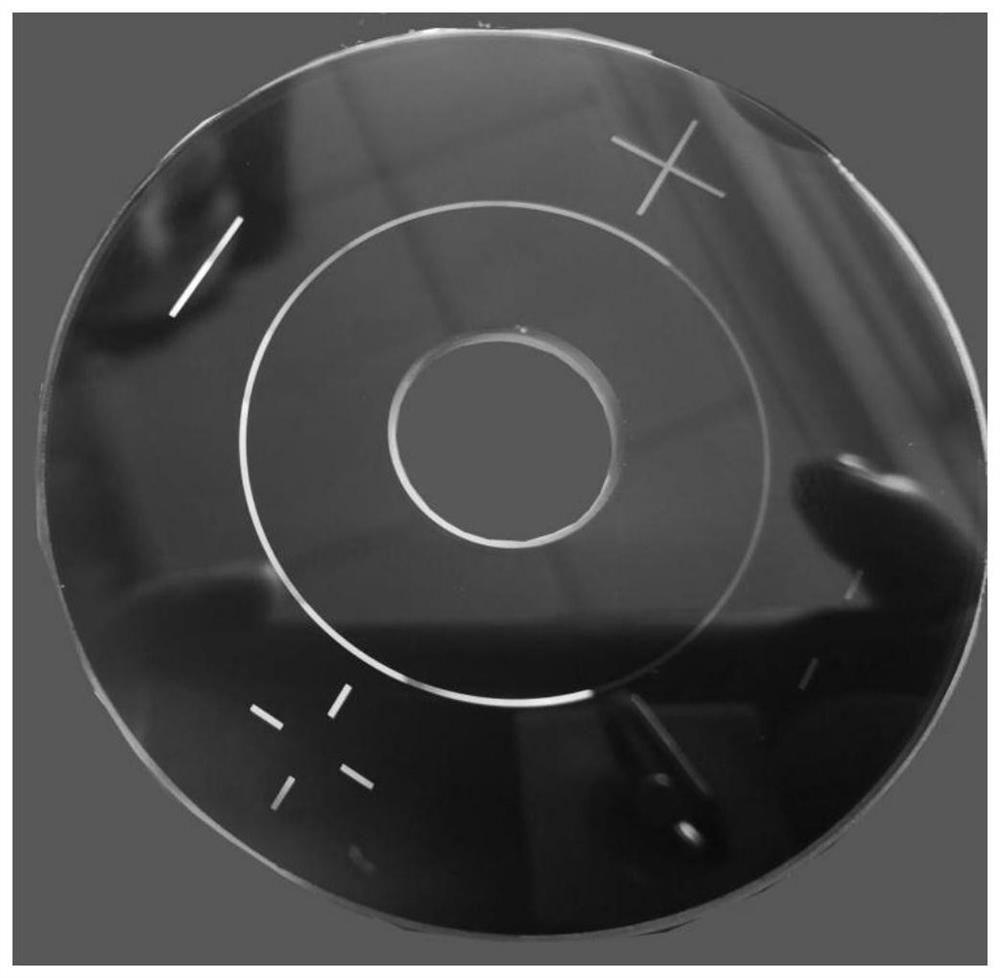

Image

Examples

Embodiment 1

[0039] Prepare 10kg multi-purpose polishing liquid main liquid:

[0040] Component A: 20 g of hexamethylenetetramine;

[0041] Ingredient B: Sodium Tripolyphosphate 50g;

[0042] Component C: 100 g of triethylenediamine;

[0043] Nonionic surfactant: lauryl oleyl alcohol 1g;

[0044] Defoamer: polyether defoamer 0.1g;

[0045] Abrasive: SiO 2 Hydrosol 1000g;

[0046] Deionized water: 8828.9g.

[0047] The preparation method is as follows: add component A to the aqueous abrasive solution, and keep stirring, then add non-ionic surfactant and component B, and fully stir, at the same time add defoamer dropwise until the foam is eliminated, then add component C, And when the pH value reaches 11-12, the filtration and purification treatment is the main liquid of the multi-purpose polishing liquid.

[0048] (1) Configure 10000g sapphire polishing liquid and its polishing method

[0049] Mix the main liquid of multi-purpose polishing liquid with deionized water in a ratio of 1...

Embodiment 2

[0060] Prepare 10kg multi-purpose polishing liquid main liquid:

[0061] Component A: 500 g of hexamethylenetetramine;

[0062] Component B: sodium tripolyphosphate 600g;

[0063] Component C: 600g of triethylenediamine;

[0064] Nonionic surfactant: lauryl oleyl alcohol 60g;

[0065] Defoamer: polyether defoamer 100g;

[0066] Abrasive: A1 2 o 3 Hydrosol 5000g;

[0067] Deionized water: 3140g.

[0068] The preparation method is as follows: add component A to the aqueous abrasive solution, and keep stirring, then add non-ionic surfactant and component B, and fully stir, at the same time add defoamer dropwise until the foam is eliminated, then add component C, And when the pH value reaches 11-12, the filtration and purification treatment is the main liquid of the multi-purpose polishing liquid.

[0069] (1) Configure 10000g sapphire polishing liquid and its polishing method

[0070] Mix the main liquid of multi-purpose polishing liquid with deionized water in a ratio o...

Embodiment 3

[0078] Prepare 100kg multi-purpose polishing liquid main liquid:

[0079] Component A: 3000 g of hexamethylenetetramine;

[0080] Ingredient B: sodium tripolyphosphate 3000g;

[0081] Component C: 3000g of triethylenediamine;

[0082] Nonionic surfactant: 300g of lauryl oleyl alcohol;

[0083] Defoamer: polyether defoamer 500g;

[0084] Abrasive: SiO 2 Hydrosol 30000g;

[0085] Deionized water: 60200g.

[0086] The preparation method is as follows: add component A to the aqueous abrasive solution, and keep stirring, then add non-ionic surfactant and component B, and fully stir, at the same time add defoamer dropwise until the foam is eliminated, then add component C, And when the pH value reaches 11-12, the filtration and purification treatment is the main liquid of the multi-purpose polishing liquid.

[0087] (1) Configure 10000g sapphire polishing liquid and its polishing method

[0088] Mix the main liquid of multi-purpose polishing liquid with deionized water in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com