Treatment and reclamation method of (methyl) acrylic acid production wastewater

A technology for the production of wastewater and acrylic acid, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, multi-stage treatment of water/sewage, etc. It can solve the problems of unsuitable biochemical treatment and unqualified discharge, and realize the realization of wastewater resources The effect of efficient utilization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

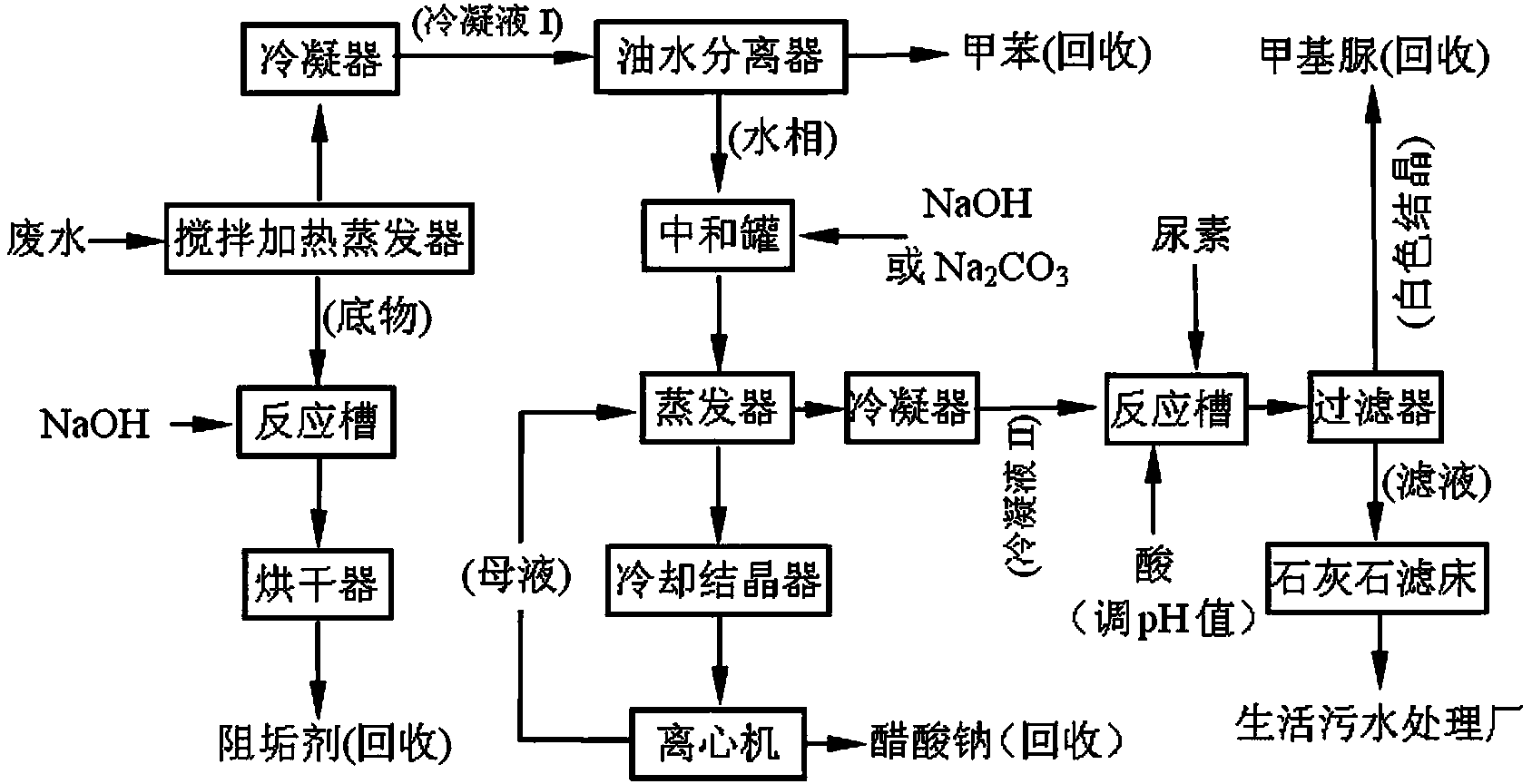

Method used

Image

Examples

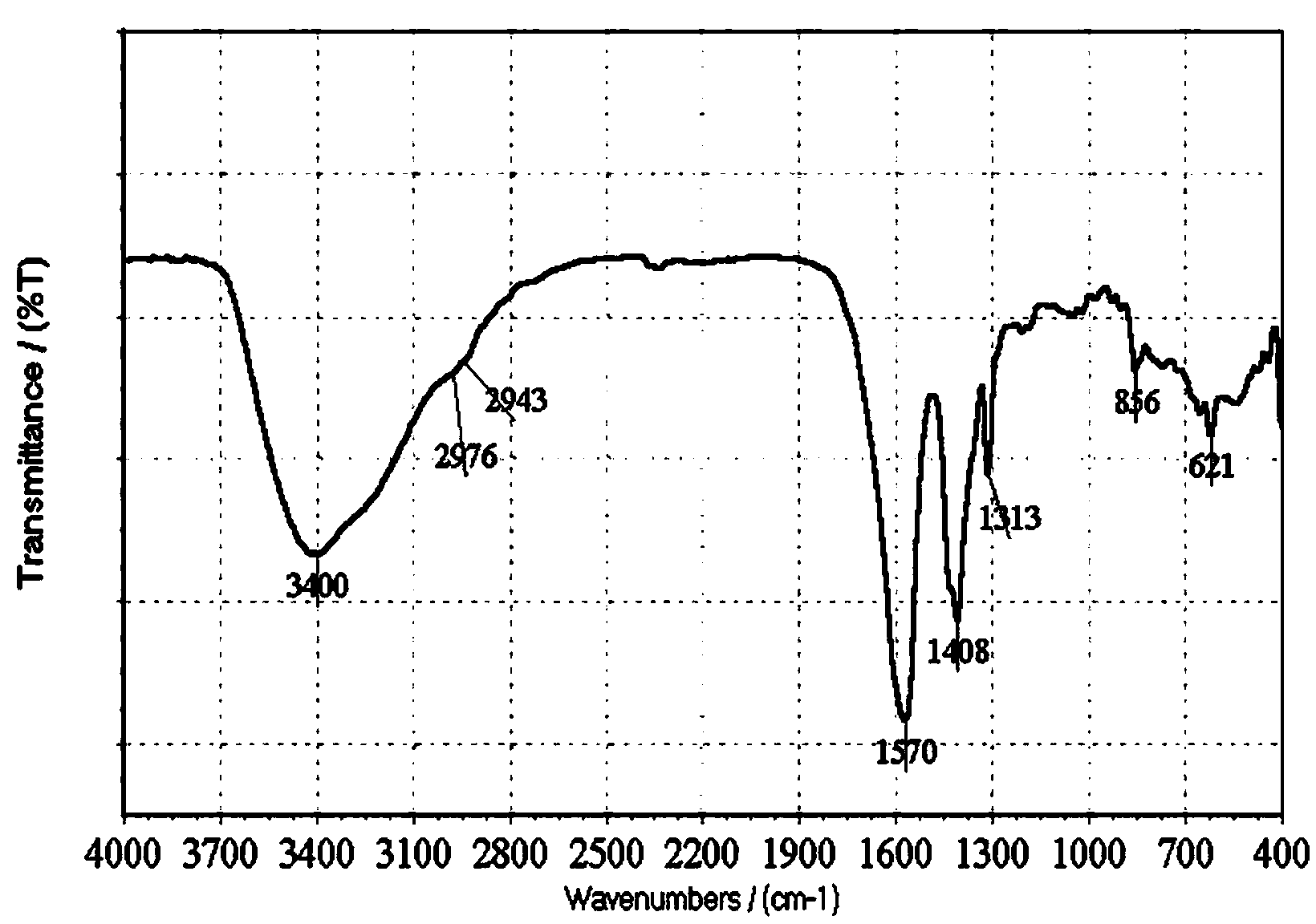

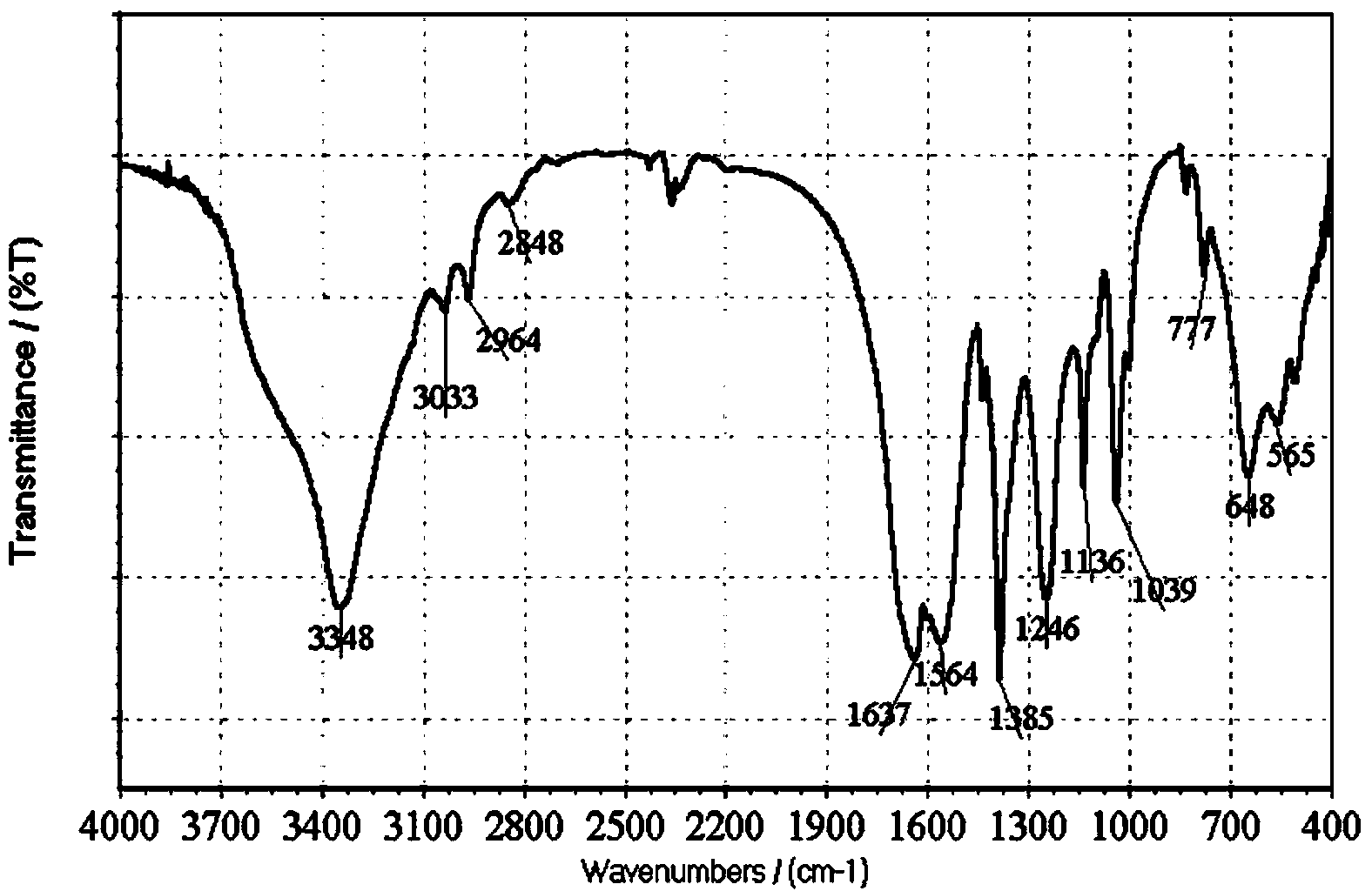

Embodiment 1

[0031] The wastewater used in this example is methacrylic acid wastewater, and its composition is shown in Table 1; the method of this example is as follows: Take 1 L of wastewater, heat it up to 90°C, stir it at a speed of 200r / min for 60min, continue to heat until boiling and evaporate, collect Condensate (I). When the Baume degree of the waste water reaches 14 degrees, dump the discharge liquid to obtain about 80g of a viscous solid-liquid mixture, add sodium hydroxide, stir and neutralize until the pH value is 8, form a uniform viscous body, and dry it at 105°C. That is, 67.5 g of boiler scale inhibitor mainly composed of (meth)acrylate mixed polymer was obtained. The obtained condensate (I) enters the oil-water separator (a pear-shaped separatory funnel is used here), and 1.4 mL of toluene is recovered; the water phase is neutralized with sodium hydroxide to a pH value of 8, and 36.8 g of sodium hydroxide is consumed. Concentrate by heating while collecting the condensat...

Embodiment 2

[0033] The wastewater used in this example is methacrylic acid wastewater, and its composition is shown in Table 1; the method of this example is as follows: Take 1 L of wastewater, heat it up to 90°C, stir at 300r / min for 30min, continue heating until boiling and evaporate, collect Condensate (I). When the Baume degree of the wastewater reaches 15 degrees, pour out the liquid to obtain about 75mL viscous solid-liquid mixture, add sodium hydroxide, stir and neutralize until the pH value is 8, and form a viscous viscous body, bake at 105 ° C After drying, 66.1 g of a boiler scale inhibitor mainly composed of (meth)acrylate mixed polymers was obtained. The obtained condensate (I) enters the oil-water separator (a pear-shaped separatory funnel is used here), and 1.6 mL of toluene is recovered; the water phase is neutralized with sodium hydroxide to a pH value of 8, and 39.5 g of sodium hydroxide is consumed. Concentrate by heating while collecting the condensate (II). When the ...

Embodiment 3

[0035] The wastewater used in this example is acrylic acid wastewater, and its composition is shown in Table 1; the method of this example is as follows: take 1 L of wastewater, heat it up to 90°C, stir it at a speed of 200r / min for 60min, continue heating until it boils and evaporate, and collect the condensate (I). When the Baume degree of the wastewater reaches 14 degrees, pour out the liquid, about 45mL, add sodium hydroxide, stir and neutralize until the pH value is 8, a black viscous body is formed, and dry at 105°C to obtain (methyl) 36.6g of boiler scale inhibitor mainly composed of acrylate mixed polymer. The obtained condensate (I) enters the oil-water separator (a pear-shaped separatory funnel is used here), and 0.3 mL of toluene is recovered; the water phase is neutralized with sodium hydroxide to a pH value of 8, and 23.1 g of sodium hydroxide is consumed. Concentrate by heating while collecting the condensate (II). When the Baume degree of the feed liquid reach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap