Computerized embroidery machine automatic baseline replacing apparatus

An embroidery machine, automatic technology, applied in the direction of embroidery machine, embroidery machine mechanism, textiles and paper making, etc., can solve the problems of short effective working time of computerized embroidery machine, long downtime of embroidery machine, low benefit of embroidery products, etc. Save time for changing bobbin case, improve effective working time, and easy to manage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

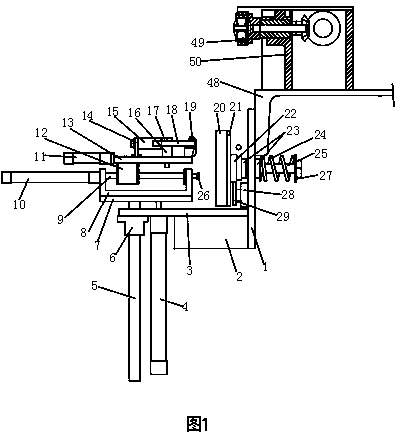

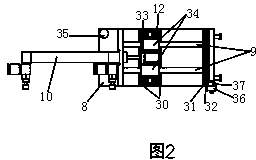

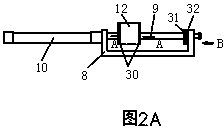

[0030] The automatic bobbin thread changing device of the computerized embroidery machine of the present invention is composed of three major parts: an embroidery machine hooking fork turning mechanism, an automatic bobbin case changing mechanism and a bobbin case storage mechanism for storing spare bobbin cases. The specific structure is as follows:

[0031] Such as Image 6 , Figure 6A As shown, the cylindrical body of the four cylinders 57 in the overturning mechanism of the thread buckle of the embroidery machine is fixedly installed on the support 58, and the support 58 is fixedly installed on the base plate 59, and the base plate 59 is fixedly installed on the shuttle bed seat 50. Wire electromagnet 53 is fixedly installed on the buckle wire electromagnet seat 54, and buckle wire electromagnet seat 54 can rotate around the thread fork shaft 60 on the shuttle bed seat 50 as a fulcrum, and the axle of cylinder four 57 is connected with hinge 55, connecting rod 56 and Wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com