Method for water interception curtain grouting in leakage concrete

A curtain grouting and concrete technology, applied in water conservancy engineering, marine engineering, construction, etc., can solve problems such as economic losses, affecting the continuous operation of power stations, and achieve stable operation, good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

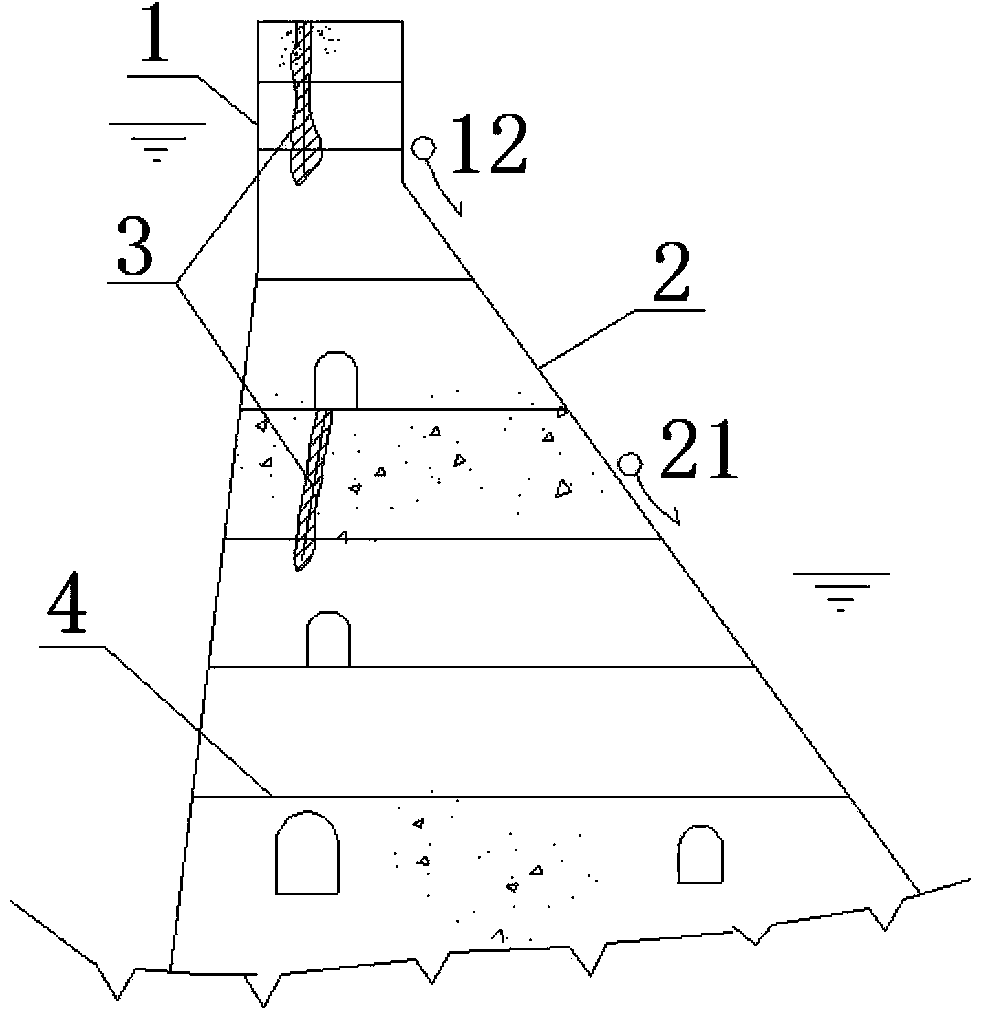

[0031] The purpose of the present invention is to overcome the drawbacks in the prior art that the reservoir area must be drained to store water for plugging, to ensure the stability and safety of buildings, and to provide a plugging method under dynamic water conditions. Such as figure 1 As shown, there is an interlayer joint 4 between the upstream dam surface 1 and the downstream dam surface 2, and the dam has interlayer seam leakage 12 and concrete leakage 21. Low permeability, strip-shaped on the plane, and an anti-seepage structure that looks like a stage curtain on the facade, that is, the grouting curtain, also known as the water-cutting curtain 3, so as to solve the problem of concrete plugging.

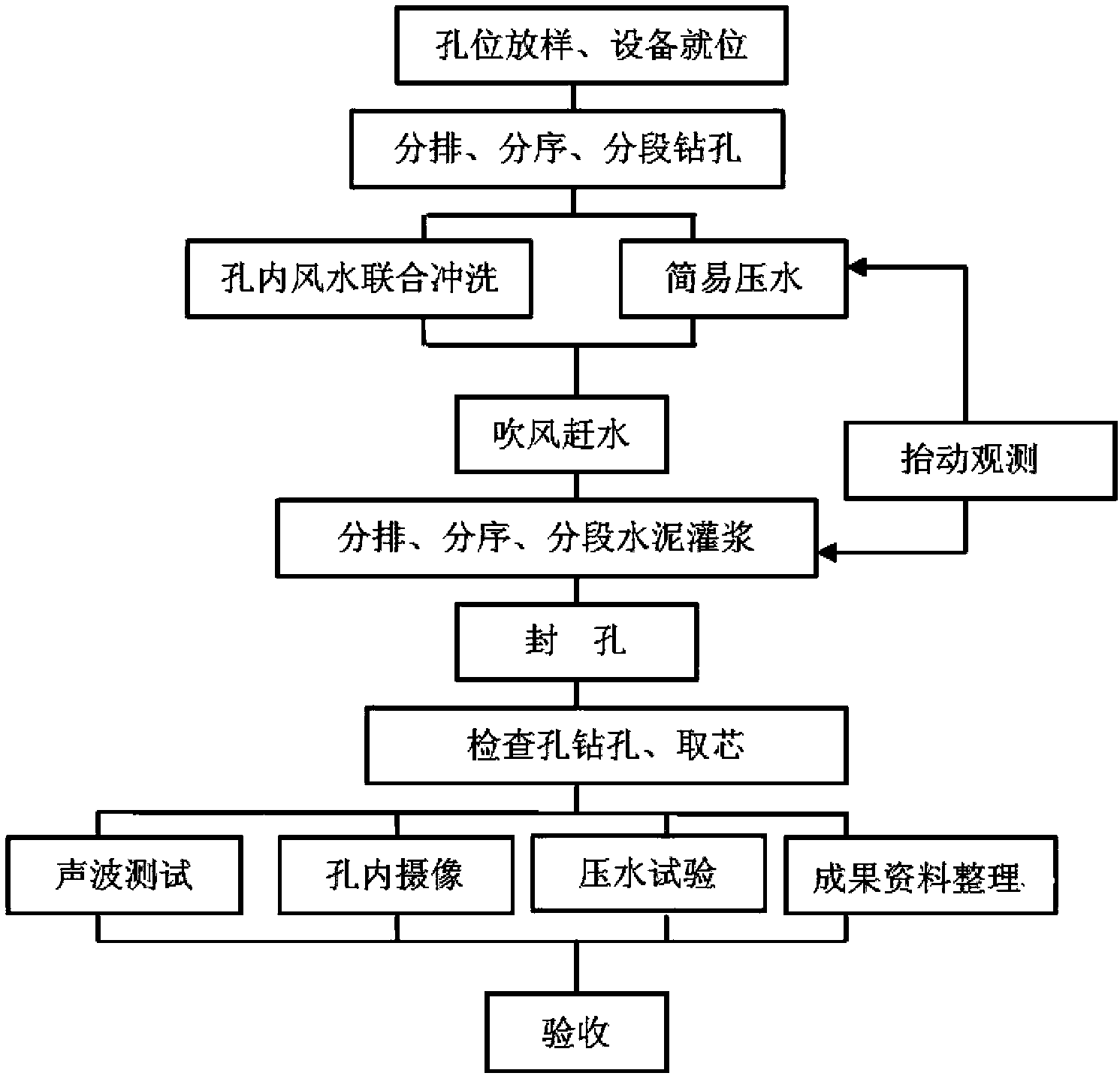

[0032] The water cut-off curtain 3 adopts the construction method of separate rows and sequential grouting. When there are multiple rows of holes, drill and grout the downstream row first, then drill and grout the upstream row, and finally drill and grout the middle row. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com