Coal furnace

A coal furnace and casing technology, applied in the field of coal furnaces, can solve the problems of low ventilation, incomplete combustion, and low combustion efficiency of coal furnaces, and achieve the effects of improving heating efficiency, increasing combustion rate, and thorough ash discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

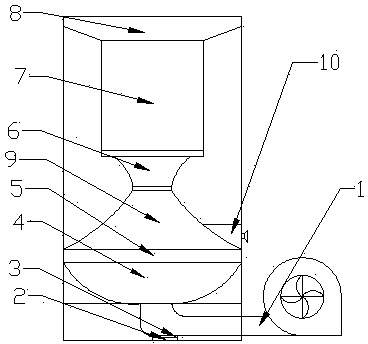

[0022] Further description will be given below in conjunction with the accompanying drawings

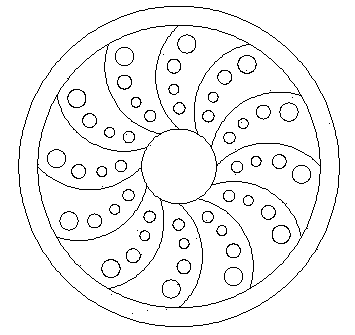

[0023] like Figure 1~4 Shown: a coal stove, including a casing, a flame-retardant layer, and a combustion chamber, the combustion chamber is set in the casing through the flame-retardant layer, the coal stove also includes a diversion chamber, an air intake pipe 1, and the air intake pipe 1 The combustion chamber is arranged on the upper part of the diversion chamber and communicated with the diversion chamber. The diversion chamber, the air intake pipe 1, and the combustion chamber are installed in the shell, and the gap between them and the shell is filled with a flame-retardant layer;

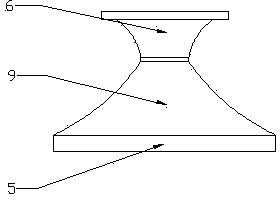

[0024] The deflector cavity includes a deflector 9 and a bottom case 4, and the deflector 9 is a gradually expanding horn-shaped structure, on the inner wall of the horn, from the edge with a larger diameter to the smaller diameter of the horn. The small edge is symmetrically provided with severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com