Medium-high temperature glass metal evacuated tube solar collector

A technology of solar collectors and glass metal, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., and can solve problems such as rising use costs, difficult processing, and easy freezing and cracking of tubes , to achieve high heat collection efficiency, reduced damage rate, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

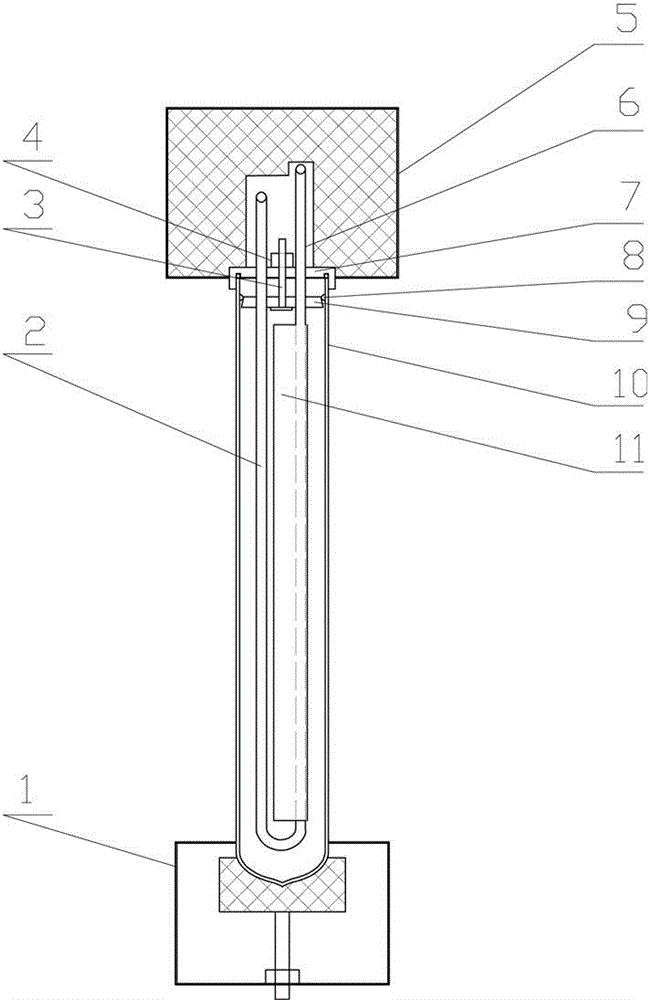

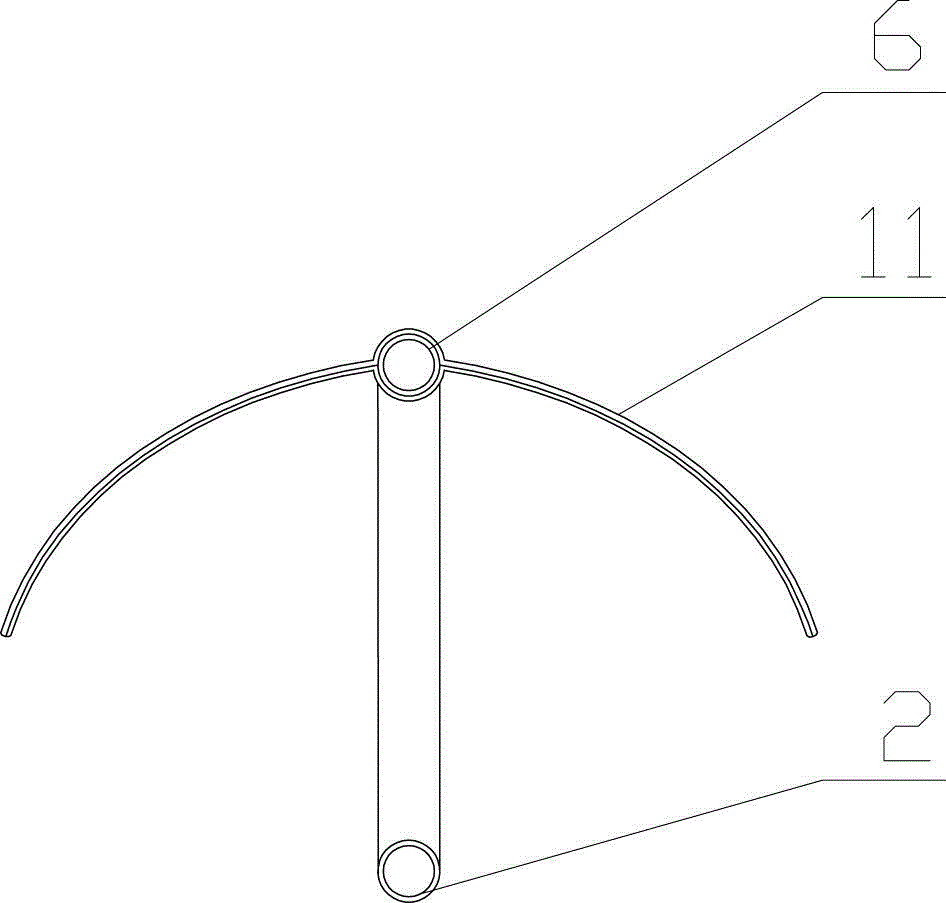

[0014] Such as figure 1 , figure 2 As shown, a medium-high temperature glass metal vacuum tube solar collector adopts a tubular structure, the upper open end of the tube body is connected to the header 5, the lower closed end of the tube body is supported by the bottom support 1, and the tube body is a single layer The heat collecting tube 10 has a "U"-shaped tube in the inner cavity of the single-layer heat collecting tube 10. One standpipe of the "U"-shaped pipe is the cold water pipe 2, and the other standpipe is the hot water pipe 6. There is a fin plate 11, the fin plate 11 is a double-layer pressing structure, the hot water pipe 6 is pressed on the central part of the fin plate, the cross section of the fin plate 11 is arc-shaped, and the outer surface of the arc-shaped fin plate 11 is coated with suction Heat layer: a horizontal ring convex 8 is designed on the inner wall circumference near the open end of the upper part of the single-layer heat collecting tube 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com