Method and device for inspection measurement of fan-shaped section base of continuous casting machine

A continuous casting machine segment and measurement method technology, which is applied in the direction of measuring device, mechanical gap measurement, height/level measurement, etc., can solve the problems of affecting the measurement adjustment accuracy, inconvenient measurement distance, and many obstacles, so as to improve construction Quality, simple structure, and the effect of improving the speed of measurement adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

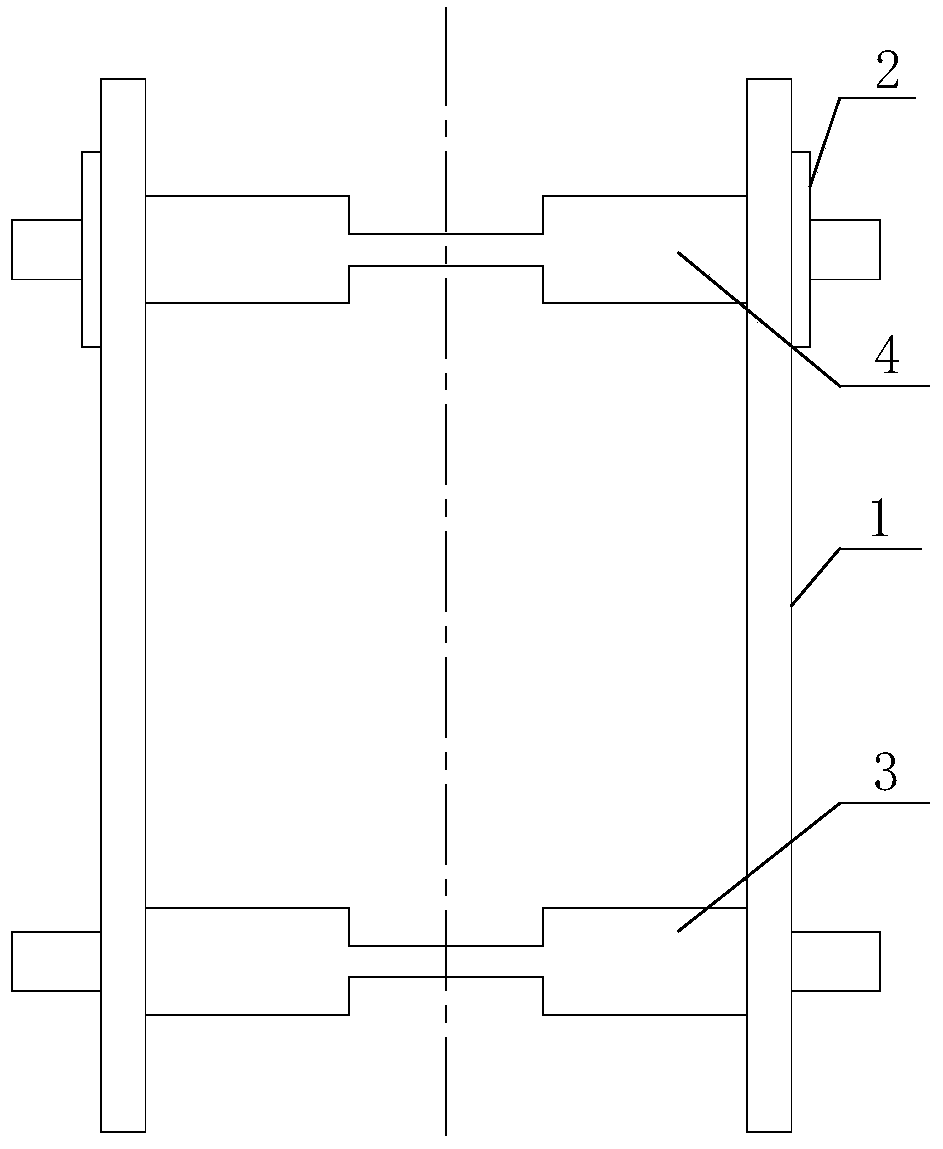

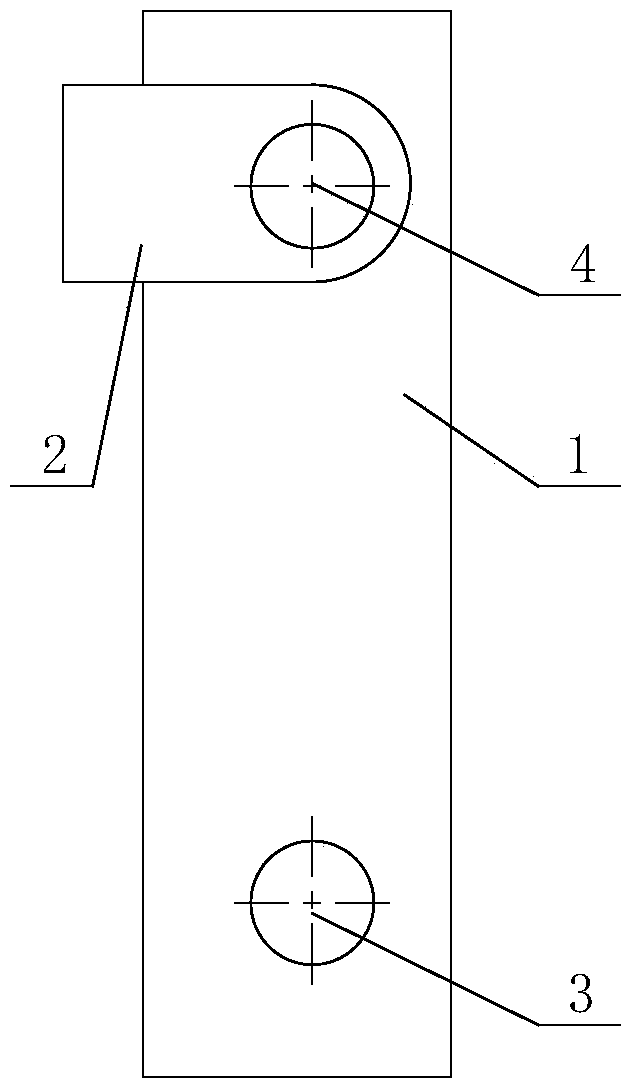

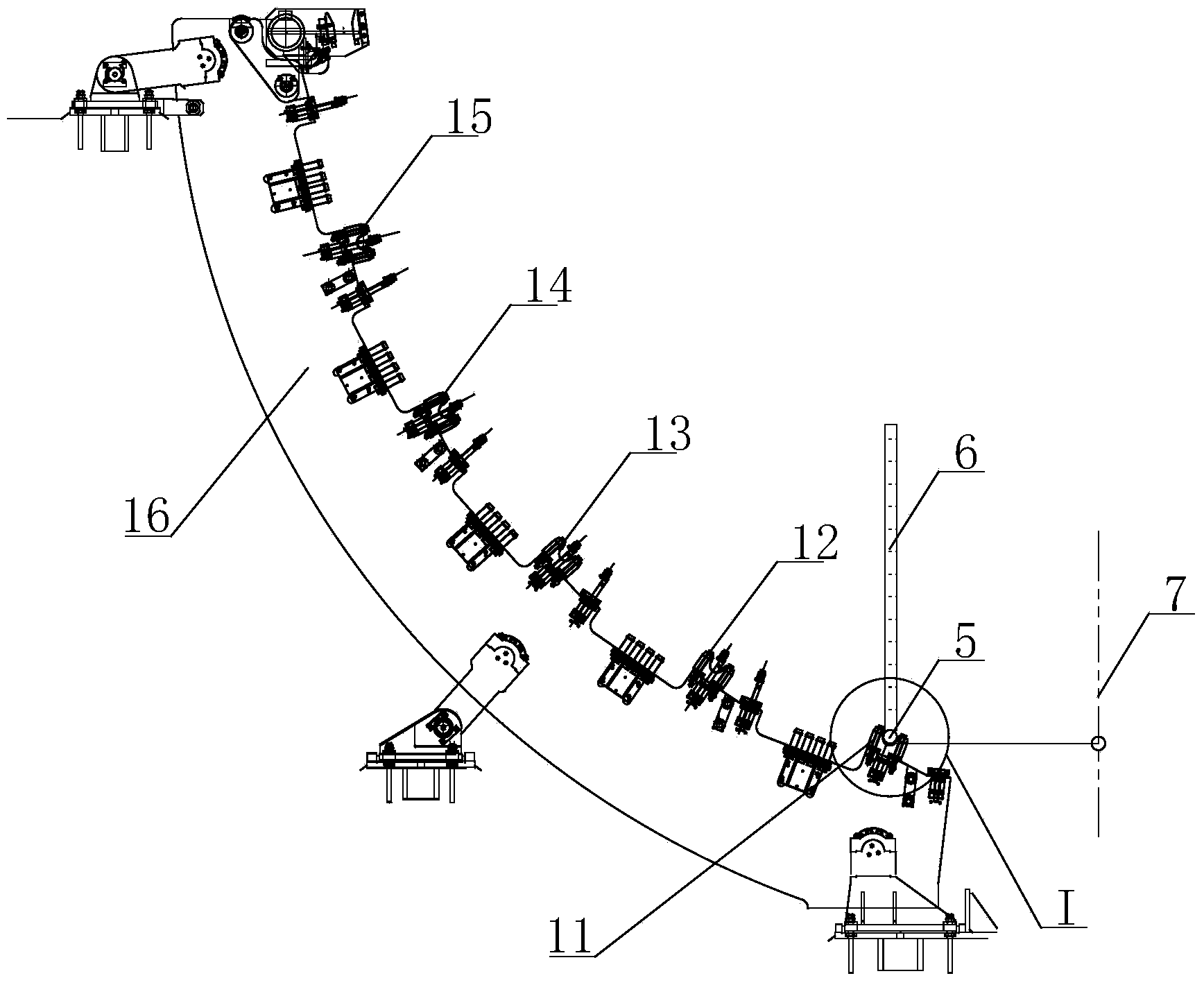

[0039] See Figure 1-Figure 6 , firstly take the 5# positioning U-shaped seat 11 of the arc segment 16 (the last arc segment) as the starting point, and adjust the gaskets in the two directions of the U-shaped seat 11a and b by adjusting 5# according to the measured deviation data , so that its deviation is within the allowable deviation range (make sure that the deviation is in the same direction when adjusting).

[0040]Based on the 5# positioning U-shaped seat 11 of the sector 16, adjust the 4# positioning U-shaped seat 12, and then adjust the 3# positioning U-shaped seat 13 based on the 4# positioning U-shaped seat 12, and so on. The positioning U-shaped seat of 16 has been adjusted. The specific adjustment method takes 5# positioning U-shaped seat 11 as a reference to adjust 5# positioning U-shaped seat 11 as an example: put two false shafts: false shaft 1 5 and false shaft 2 9 on 5# and 4# positioning U-shaped In the seat 12, use the N3 level to measure the elevation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com