Overcurrent detection circuit

An overcurrent detection and circuit technology, applied in the direction of measuring electrical variables, measuring current/voltage, measuring devices, etc., can solve problems such as bandwidth limitation and difficulty in achieving fast response, and achieve the effect of avoiding misjudgment and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

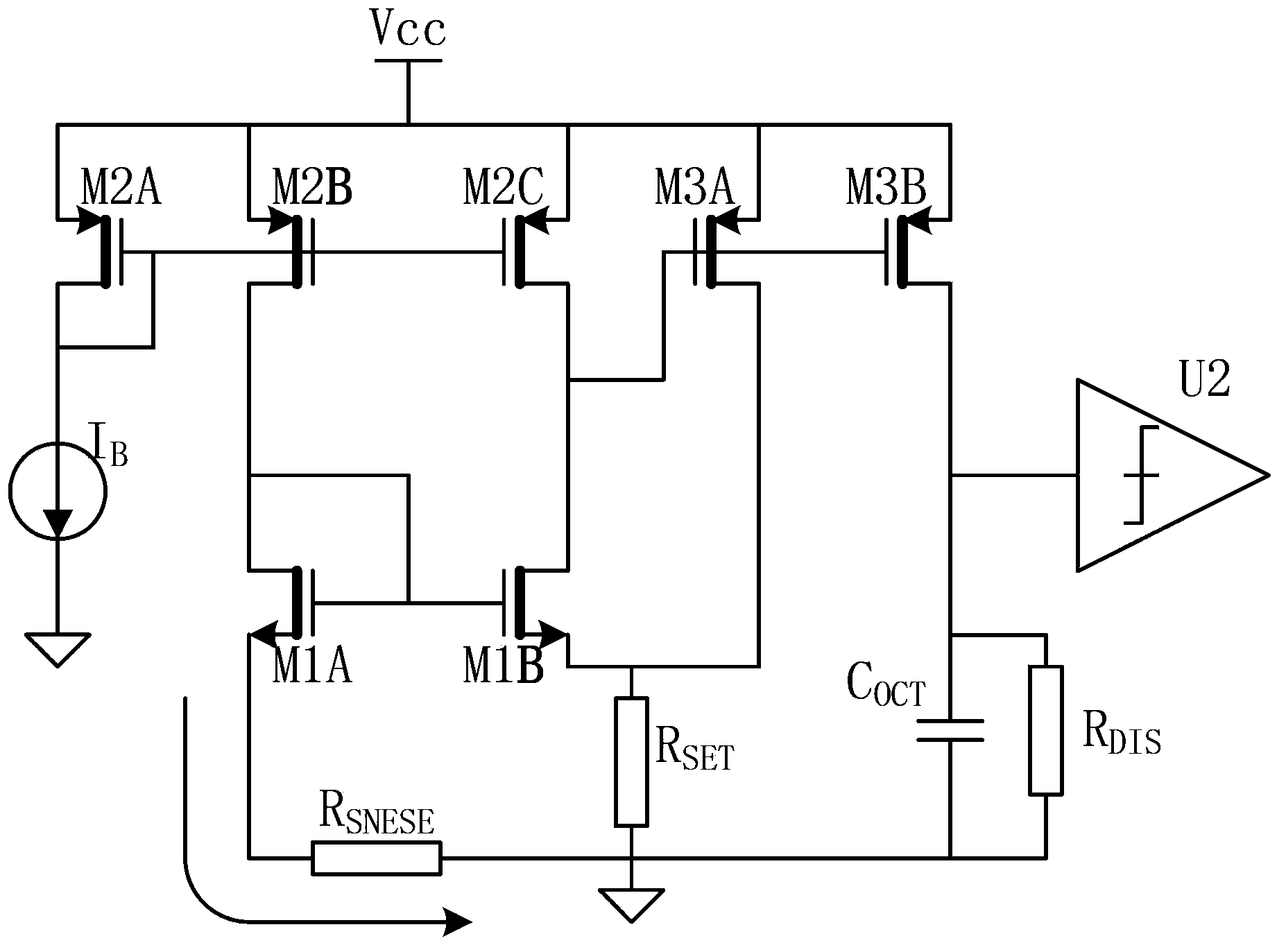

Embodiment 1

[0023] like figure 2 As shown, the overcurrent detection circuit of Embodiment 1 of the present invention includes a current detection resistor R for sampling the operating current of the system under test SENSE , a voltage comparator U2 with an overcurrent threshold, a current source I B , voltage source Vcc, overcurrent threshold setting resistor R SET , delay capacitor C OCT , the bleeder resistor R DIS , the first N-type MOS transistor M2A, and the second N-type MOS transistor M2B, the third N-type MOS transistor M2C, the fourth N-type MOS transistor M3A, the fifth N-type MOS transistor M3B, the first P Type MOS transistor M1A and the second P-type MOS transistor M1B, wherein, the first P-type MOS transistor M1A and the second P-type MOS transistor M1B are paired, the first N-type MOS transistor M2A, the second N-type MOS transistor M2B and the third The N-type MOS transistor M2C is paired, the fourth N-type MOS transistor M3A is paired with the fifth N-type MOS trans...

Embodiment 2

[0031] Embodiment 2 of the present invention is basically the same as Embodiment 1, and their difference is that in practical applications, taking into account the differences in the tested system, such as standby current, device value and other factors, this Embodiment 2 can be based on a specific proportional relationship The MOS tubes replace the above paired MOS tubes, that is: the first P-type MOS tube M1A and the second P-type MOS tube M1B are proportional MOS tubes, the first N-type MOS tube M2A, the second N-type MOS tube M2B and The third N-type MOS transistor M2C is a proportional MOS transistor, the fourth N-type MOS transistor M3A and the fifth N-type MOS transistor M3B are proportional MOS transistors, that is, any channel of a proportional MOS transistor The lengths are consistent and the channel widths are proportional, wherein the ratio of the second N-type MOS transistor M2B to the third N-type MOS transistor M2C is equal to the ratio of the first P-type MOS tr...

Embodiment 3

[0033] Embodiment 3 of the present invention is that on the basis of Embodiment 1 or Embodiment 2, at least one voltage comparator U2 is added, and the input terminals of each voltage comparator U2 are respectively connected to the fifth N-type MOS transistor M3B and the delay capacitor C OCT connection point, and the overcurrent threshold of each voltage comparator U2 is incremented. Because of the delay capacitor C in the present invention OCT The delay time generated on is inversely proportional to the overcurrent current of the system under test, that is, the capacitance C OCT The delay time generated on the above can be adaptive to the overcurrent current of the system under test. Therefore, the present invention does not need to set different delay times on each voltage comparator as in the prior art, thereby realizing continuous control and improving the overcurrent The detection reliability of the detection circuit reduces the debugging cost of the overcurrent detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com