High-speed electrified rail traction line protective belt load test method

A technology of electrified railway and load test, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of charging power (small charging current, line protection band, low voltage level, short line distance, etc., and achieve strong on-site operability performance, to achieve the effect of mutual verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

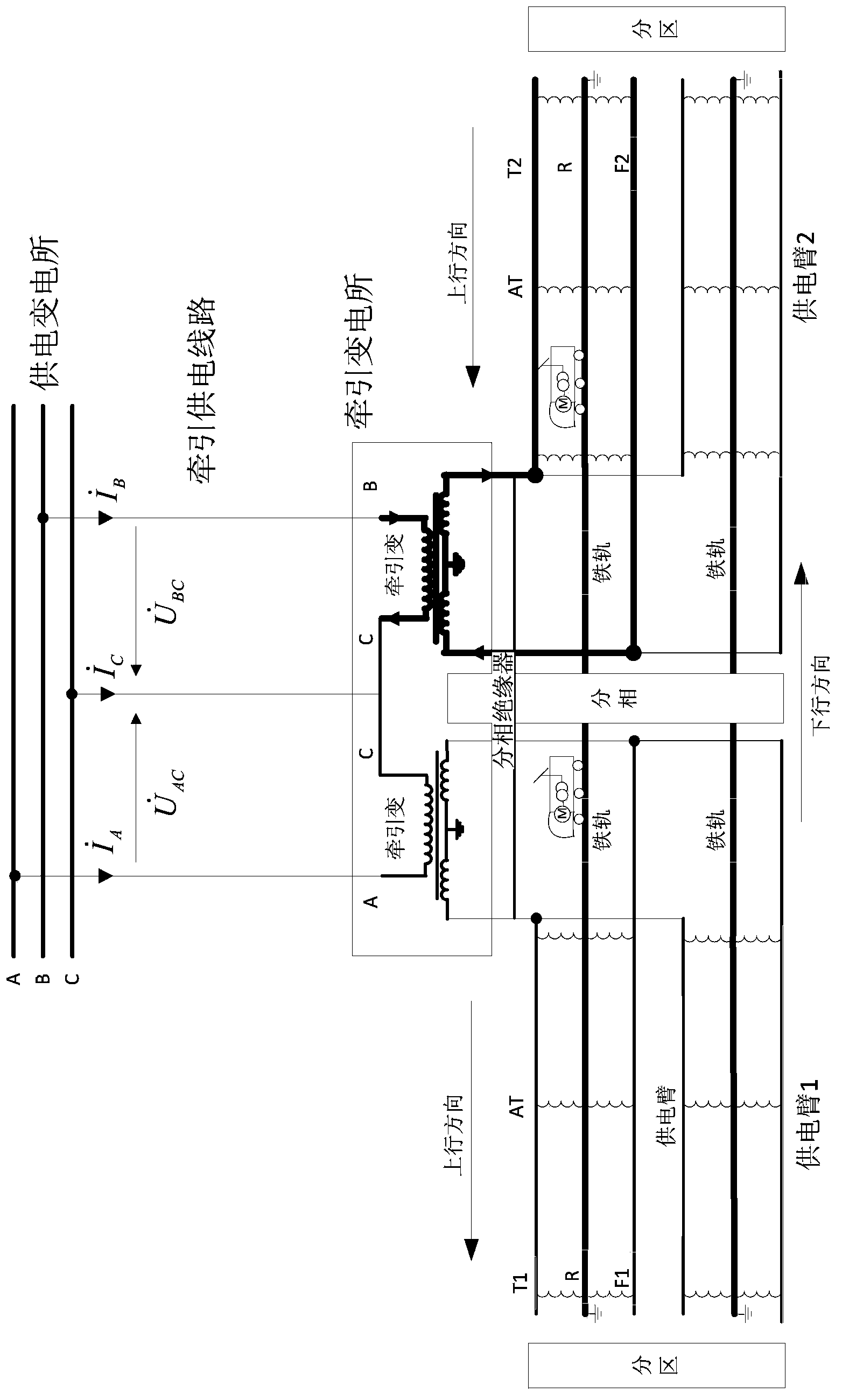

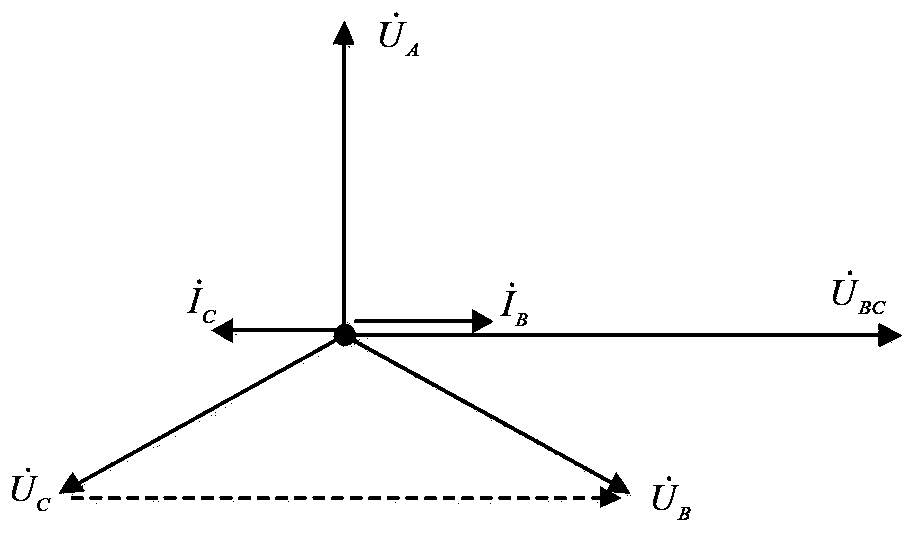

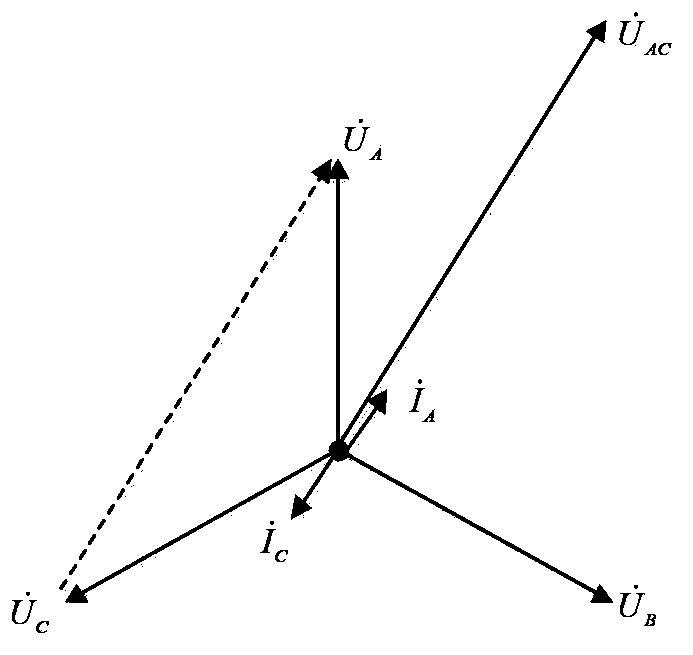

[0041] The method for checking the load of the high-speed railway traction power supply line protection belt in the present invention, on the basis of analyzing the relationship between the voltage and current phase of the traction power supply system under the different wiring of the traction transformer and the different operating conditions of the electric locomotive, proposes to use the operating state of the electric locomotive in the power supply section Judgment, comprehensive judgment by using the sampling value of the busbar protection device, and judgment by using the locomotive closing inrush current are three kinds of load verification methods for traction line protection to adapt to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com