Deep low damage acidizing fluid

An acidizing fluid and depth technology, applied in the field of acidizing fluid, can solve problems such as excessive reservoir corrosion, particle migration, and reservoir particle loosening, and achieve strong on-site operability, increased action distance, and improved pore-permeability conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

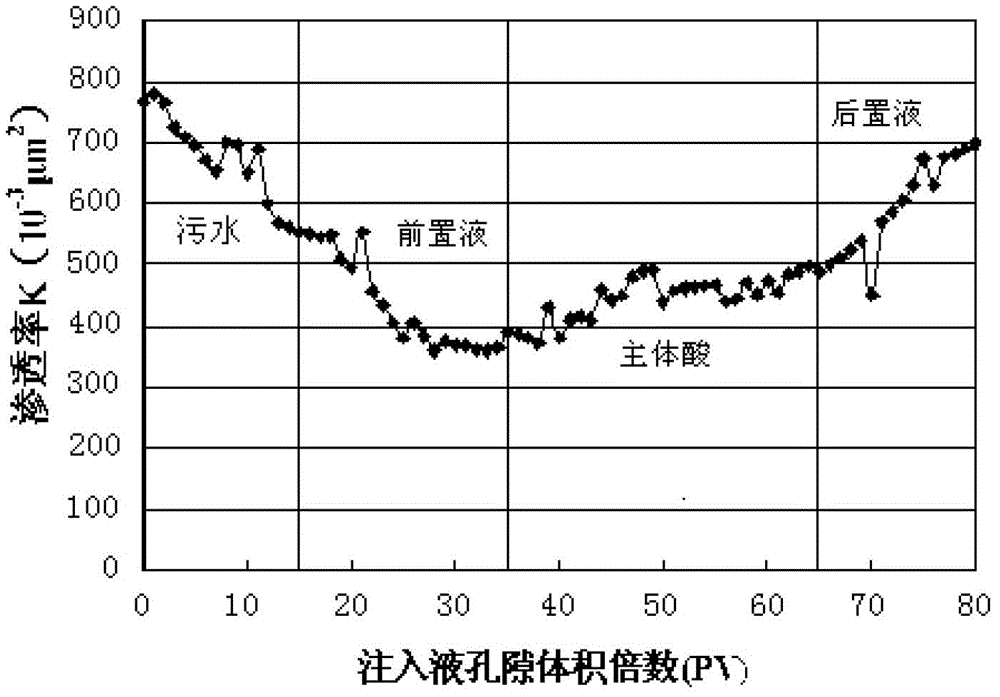

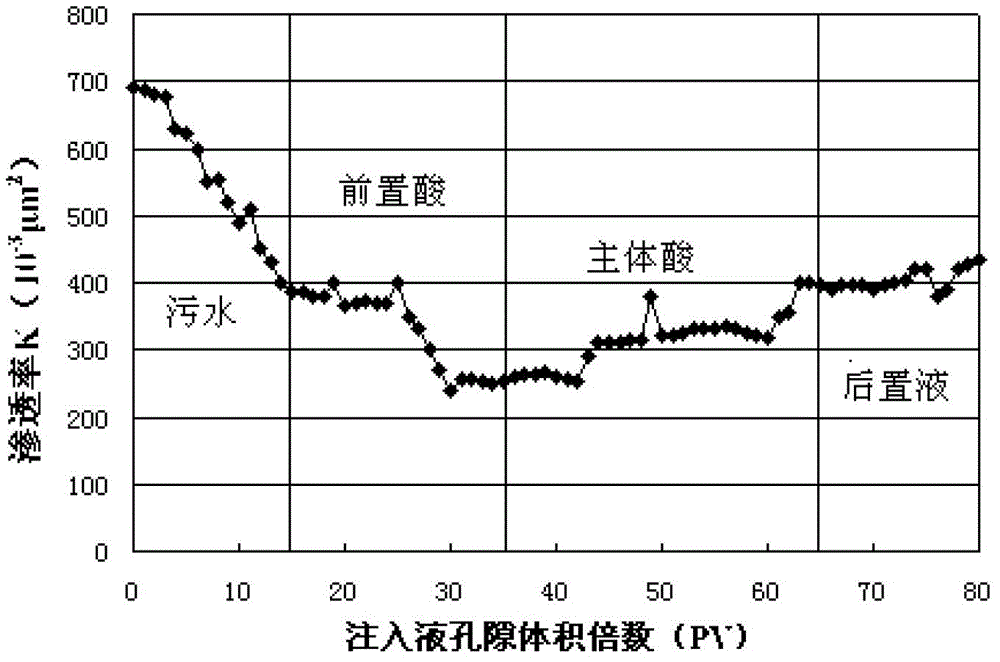

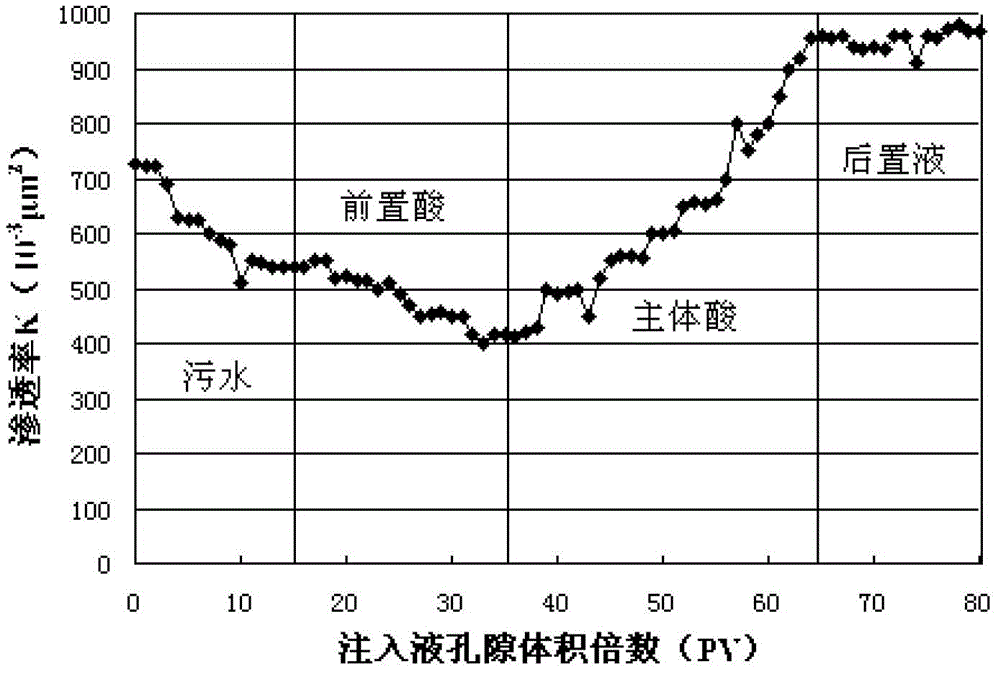

Image

Examples

Embodiment Construction

[0046] The present invention will be further explained below in conjunction with specific examples and specific proof experiments:

[0047] The following proves that the deep and low-damage acidification solution used in the experiment is based on the total weight of the acidification solution and its composition is:

[0048] DH6%;

[0049] Fluoroboric acid 3%;

[0050] Dodecyl trimethyl ammonium chloride 3%;

[0051] HCl4%;

[0052] Corrosion inhibitor 1%;

[0053] Anti-swelling agent 1.5%;

[0054] Demulsifier 1%;

[0055] 80.5% of water;

[0056] The DH in the composition of the acidification solution is compounded by oxalic acid, benzenesulfonic acid and sulfamic acid in a molar ratio of 2:1:1.

[0057] The preparation method of the corrosion inhibitor in the above-mentioned acidification liquid composition is:

[0058] a) Add 129g of quinoline to a four-necked flask equipped with a stirrer, reflux condenser and thermometer, and start heating;

[0059] b) When the temperature rises to 90°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com