Frost-resisting gel fortifier and application thereof

A technology of enhancer and cryogel, which is applied in the direction of freezing/cooling preservation of meat/fish, etc., to achieve the effects of improving gel forming ability, improving water retention performance, and improving antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

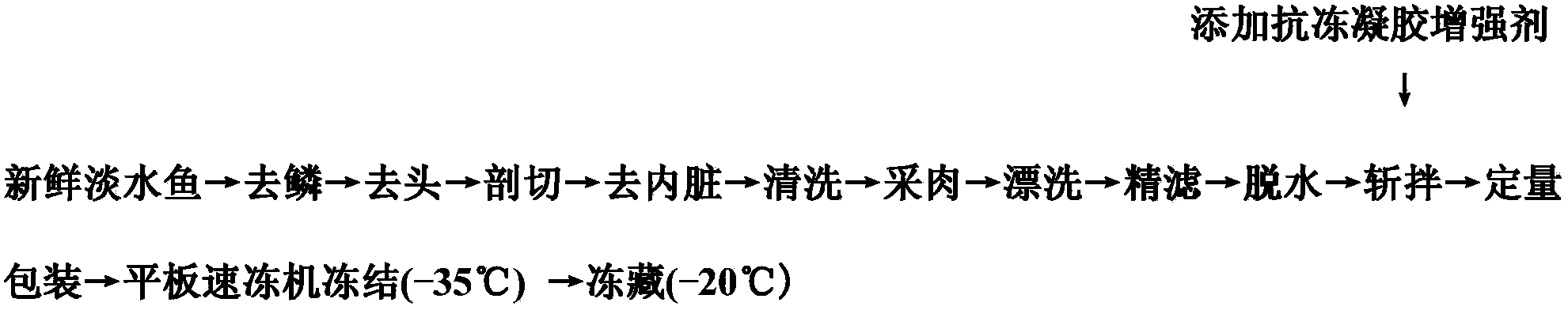

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation Example

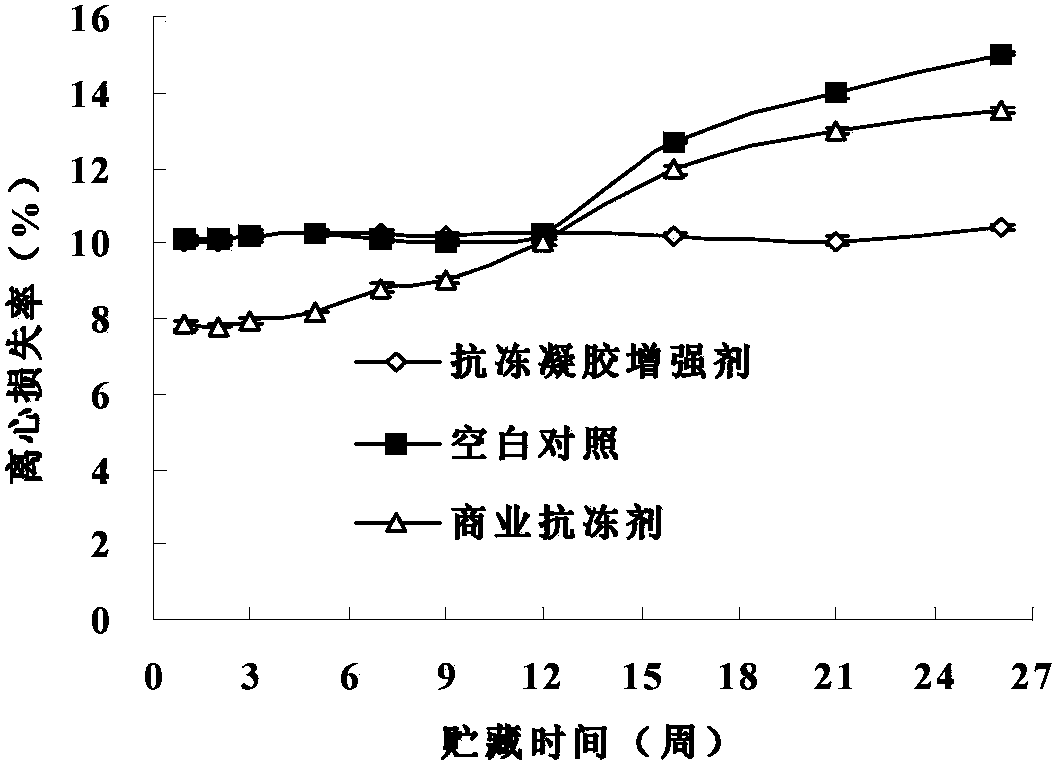

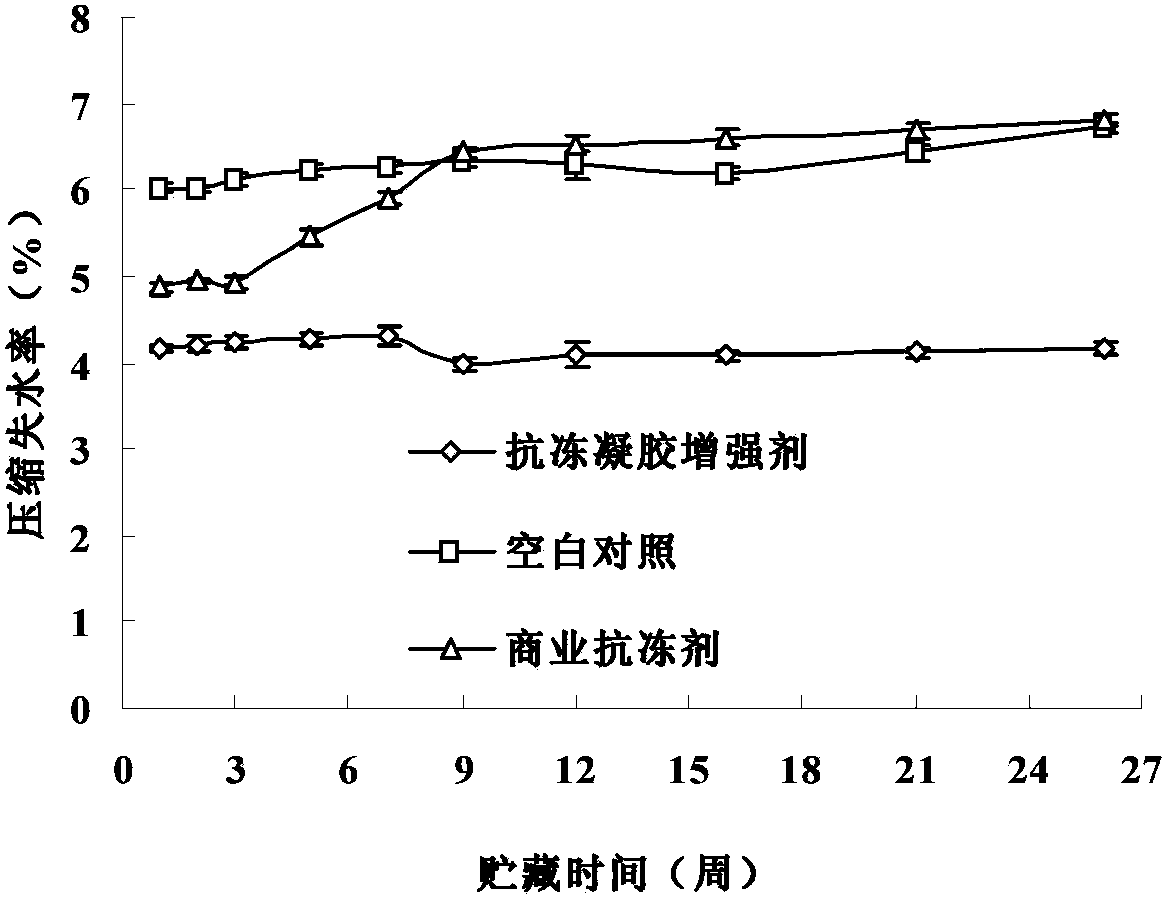

[0039] The applicant screened and determined the formulation of the antifreeze gel enhancer through a combination of single factor and orthogonal experiments, taking the water retention performance, antifreeze performance and gel performance of surimi during frozen storage as indicators, and the specific results are as follows.

[0040]The present invention studies the effects of polyhydroxy sugars on the freezing rate, heat transfer rate and low-temperature phase transition of surimi. One group without any additives was used as the blank control group, and the remaining six groups were added with 4% sucrose, then added with 4% sorbitol, 4% acetic esterified starch, 4% cross-linked esterified starch, 4% hydroxypropylated starch, 4% cross-linked hydroxypropyl starch, 0.5% konjac powder, research found that added sugars have a certain antifreeze effect, among them, the surimi group added 4% acetate starch + 4% sucrose, the gel Strength, Ca...

Embodiment 2

[0047] Embodiment 2 The embodiment in which all raw materials are calculated with physical quantities (unit of weight: kilogram or kilogram)

[0048] The present embodiment is based on 100kg of fresh surimi raw materials. The specific raw material is to take about 400kg of fresh freshwater fish for meat rinsing. After processing according to the production method of Example 1, 100kg of fresh surimi is taken, and antifreeze and coagulation prepared by Example 1 are used. Glue enhancer (the proportioning by weight is as follows: sodium lactate: 0.1~0.4kg; sodium citrate: 0.3~0.7kg; modified starch (available from commercially available cross-linked esterified starch, hydroxypropylated starch or cross-linked Obtain the first in hydroxypropyl starch): 1~2.5kg; Sucrose: 1.5~3kg; Transglutaminase: 0.3~0.7kg (preferred embodiment formula of the present invention: the raw material proportion by weight is as follows (Based on 100kg of fresh surimi): sodium lactate: 0.2-0.3kg; sodium ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com