Cefprozil tablet and preparation method thereof

A technology of cefprozil and propylene tablets, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve problems such as difficult to meet quality requirements, low dissolution rate, poor stability, etc. , to achieve the effect of reducing ring-opening degradation, simple steps, good stability and dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

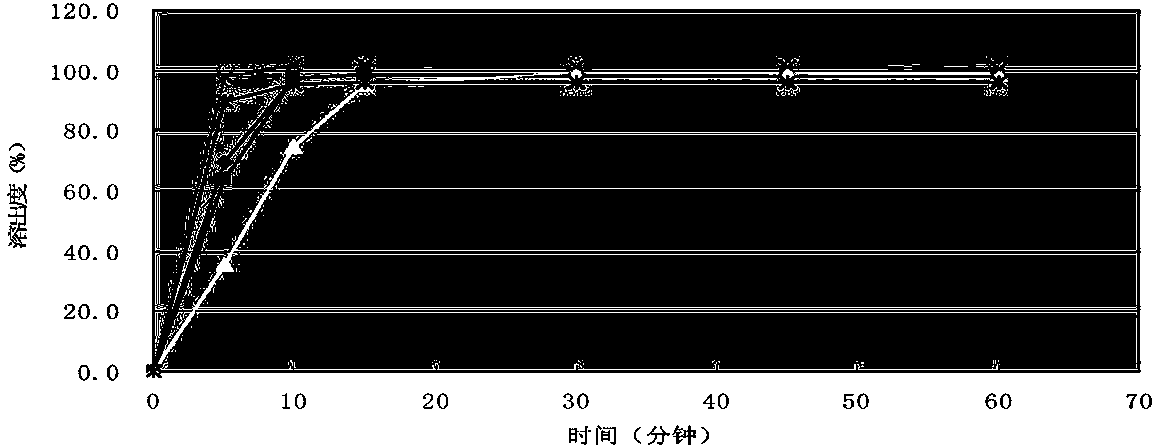

Embodiment 1

[0036] According to the following formula, cefprozil tablets were prepared with batch number 142111102.

[0037]

[0038]

[0039] The preparation steps are as follows:

[0040] (1) Sieving

[0041] Pass the cefprozil, crospovidone, and microcrystalline cellulose through an 80-mesh sieve, and directly press the lactose through a 60-mesh sieve, and collect the powder under the sieve; the purity of the cefprozil is 96.3%; the model of the microcrystalline cellulose is Microcrystalline cellulose 101.

[0042] (2) Premix

[0043] Weigh the cefprozil, microcrystalline cellulose, direct-pressed lactose, and crospovidone that have been sieved in step (1), add them to the mixer, and premix for 10 minutes;

[0044] (3) Total mixing

[0045] Weigh magnesium stearate and silicon dioxide respectively, add them to the mixer described in step (2), and mix for 10 minutes.

[0046] After mixing, insert a sampling probe into the upper, middle, and lower parts of the mixer barrel, and take samples respecti...

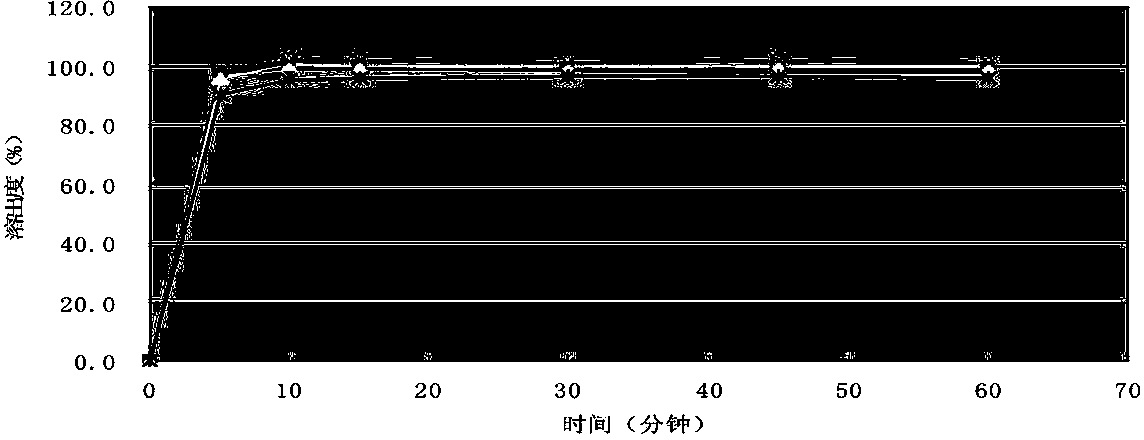

Embodiment 2

[0063] According to the following formula, cefprozil tablets were prepared with batch number 142111103.

[0064]

[0065] The preparation steps are as follows:

[0066] (1) Sieving

[0067] Pass the cefprozil, crospovidone, and microcrystalline cellulose through an 80-mesh sieve, and directly press the lactose through a 60-mesh sieve, and collect the powder under the sieve; the purity of the cefprozil is 96.3%; the model of the microcrystalline cellulose is Microcrystalline cellulose 101.

[0068] (2) Premix

[0069] Weigh the cefprozil, microcrystalline cellulose, direct-pressed lactose, and crospovidone that have been sieved in step (1), add them to the mixer, and premix for 10 minutes;

[0070] (3) Total mixing

[0071] Weigh magnesium stearate and silicon dioxide respectively, add them to the mixer described in step (2), and mix for 10 minutes.

[0072] After mixing, insert a sampling probe into the upper, middle, and lower parts of the mixer barrel, and take samples respectively, of ...

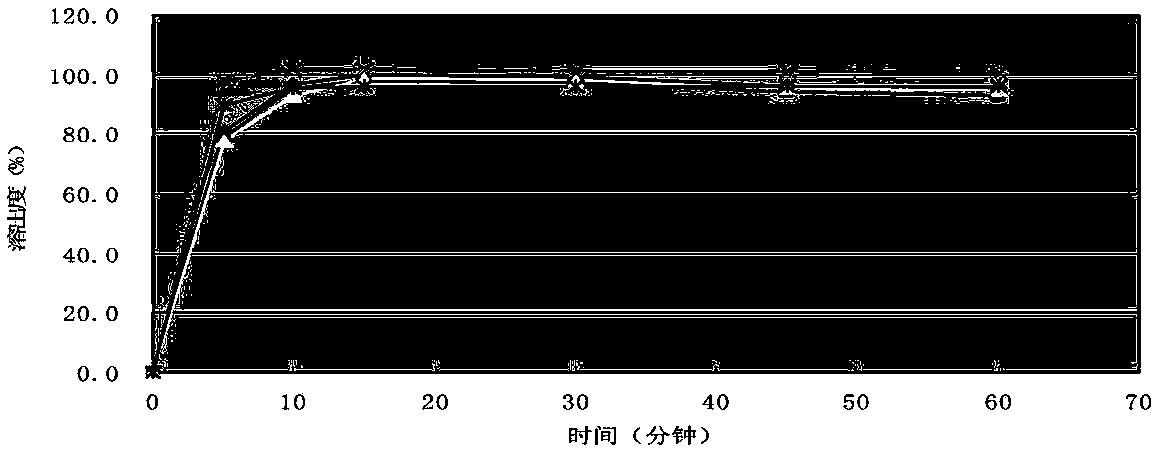

Embodiment 3

[0085] According to the following formula, cefprozil tablets were prepared with batch number 142111104.

[0086]

[0087] The preparation steps are as follows:

[0088] (1) Sieving

[0089] Pass the cefprozil, crospovidone, and microcrystalline cellulose through an 80-mesh sieve, and directly press the lactose through a 60-mesh sieve, and collect the powder under the sieve; the purity of the cefprozil is 96.3%; the model of the microcrystalline cellulose is Microcrystalline cellulose 101.

[0090] (2) Premix

[0091] Weigh the cefprozil, microcrystalline cellulose, direct-pressed lactose, and crospovidone that have been sieved in step (1), add them to the mixer, and premix for 10 minutes;

[0092] (3) Total mixing

[0093] Weigh magnesium stearate and silicon dioxide respectively, add them to the mixer described in step (2), and mix for 10 minutes.

[0094] After mixing, insert a sampling probe into the upper, middle, and lower parts of the mixer barrel, and take samples respectively, of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com