Concentrated solution dilution method

A technology of concentrated solution and dilute solution, which is applied in the field of beverages, can solve the problems of inaccurate concentration, complicated operation, and inaccurate proportioning concentration, etc., and achieve the effect of simple dilution method, simple operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

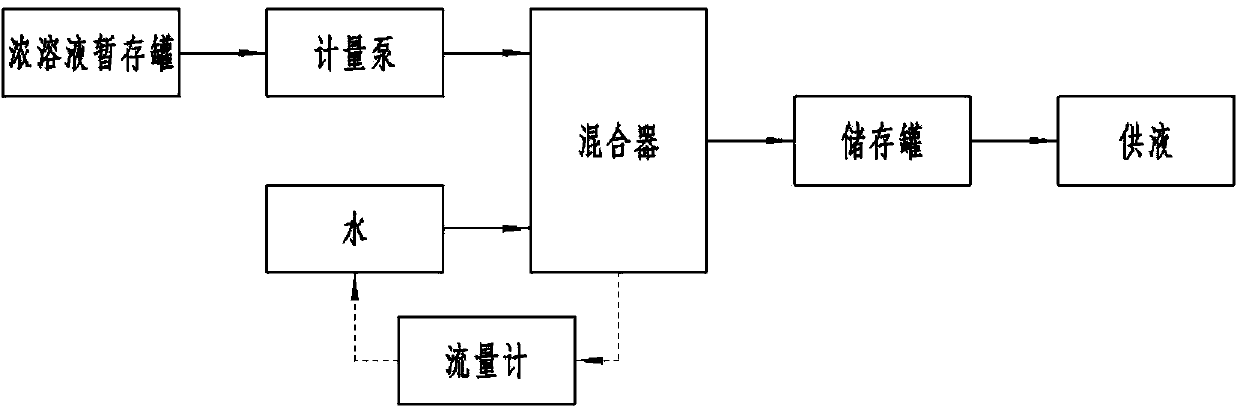

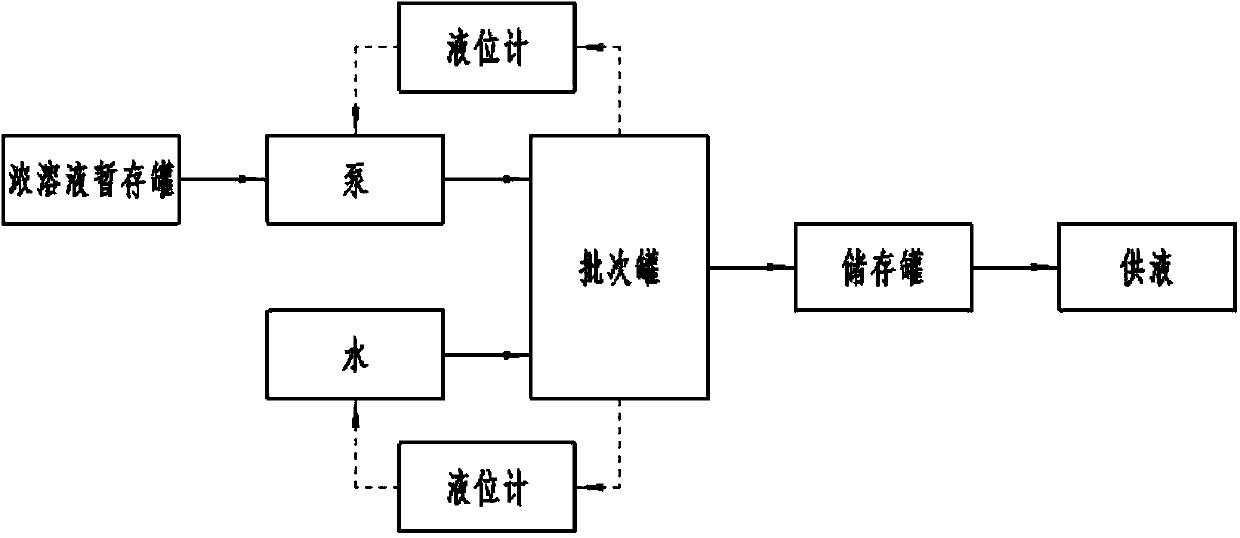

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a peracetic acid solution. When a beverage production line uses peracetic acid solution as a medium for filling equipment and packaging material sterilization, it is necessary to dilute the peracetic acid solution with a concentration of 15% to about 2000mg / kg.

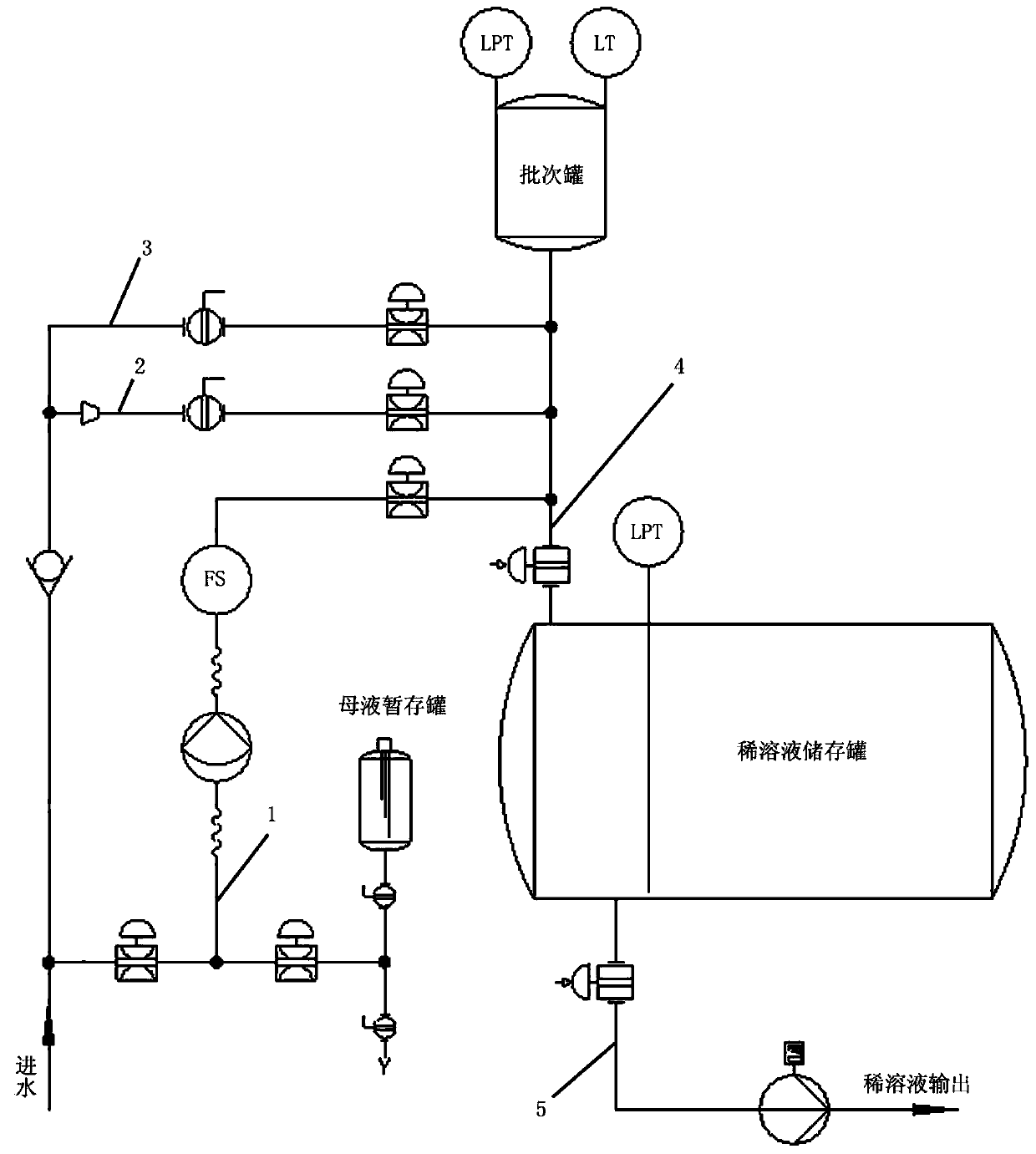

[0024] The equipment used in this embodiment is connected as image 3 As shown, a mother liquor delivery pipe 1 is provided between the mother liquor temporary storage tank and the batch tank, and a valve is provided on the mother liquor delivery pipe 1; the first water inlet pipe 3 is passed between the water tank and the batch tank, and the diameter of the pipe is smaller than that of the first inlet pipe. The second water inlet pipe 2 of water pipe 3 is connected, and the first water inlet pipe 3 and the second water inlet pipe 2 are all provided with valves; the container with the capacity greater than the batch tank is selected as the dilute solution storage tank, and the batch tank a...

Embodiment 2

[0034] A method for diluting a sodium hydroxide solution requires diluting a 40% solution to 1%.

[0035] The equipment connection used in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0036] Adopt dilution method of the present invention to dilute this solution, concrete steps are as follows:

[0037] (1) Determination of the capacity of the batch tank;

[0038] (2) According to the concentration requirements of the required configuration, set the liquid level of the concentrated sodium hydroxide solution to the batch tank, and then pump the concentrated sodium hydroxide solution from the mother liquor temporary storage tank into the batch tank until the hydrogen is oxidized Sodium concentrated solution liquid level setting amount;

[0039] (3) Set the water level setting amount for the batch tank, add water from the water tank to the batch tank to the water level setting amount, during the process of adding water, the first water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com