Vibrating ash removal device for removing ash inside ash pipeline to be cleaned

A ash cleaning device and ash cleaning technology, which are applied in the directions of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of dead ends in soot blowing, gas must be paid attention to safety, and work efficiency needs to be improved, so as to achieve the effect of high-definition ash efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

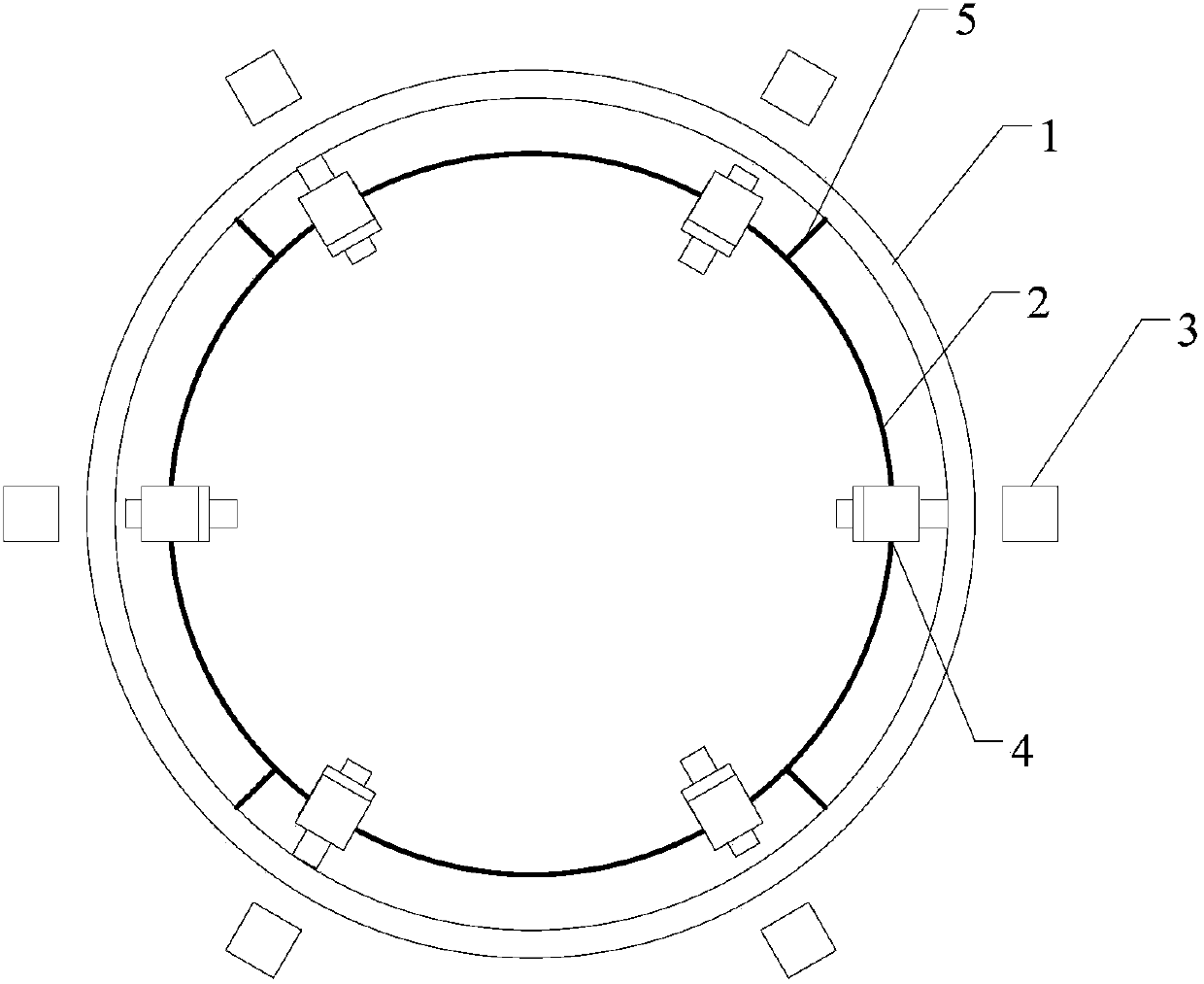

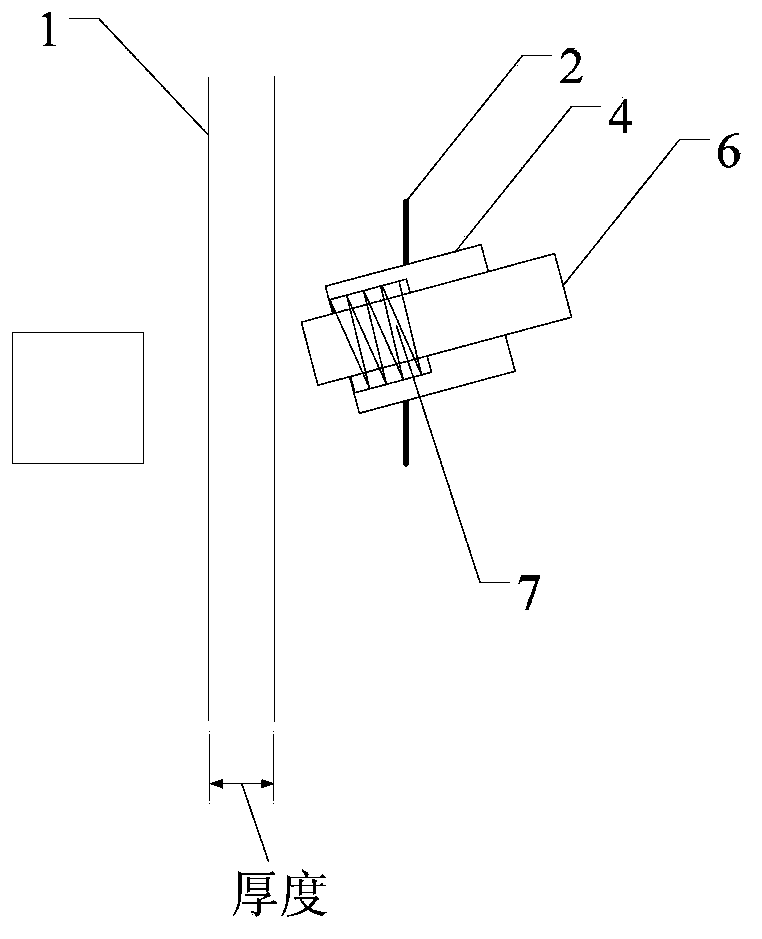

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a kind of rapping and soot cleaning device for cleaning dust from the inside of the pipeline to be cleaned. The pipeline 1 to be cleaned is vertically arranged. Fixed inside the pipeline to be cleaned, coaxial with the pipeline to be cleaned, the ring frame has at least one guide rail 4 that is inclined relative to the ring frame, and the upper end of each guide rail is relatively close to the axis of the ring frame, and the lower end The part is relatively far away from the axis of the ring frame; at least one rapping rod 6 is arranged on a guide rail and can move along the guide rail. Each rapping rod is made of iron material, and one end passes through a compression spring Connected to the rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com