Drilling machine provided with center hole and used for thin plates

A technology of thin plate and center hole, which is applied in the direction of boring/drilling, drilling/drilling equipment, and drilling templates for workpieces, etc. Excessive clamping and other problems can achieve the effect of improving drilling precision, eliminating positioning and preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

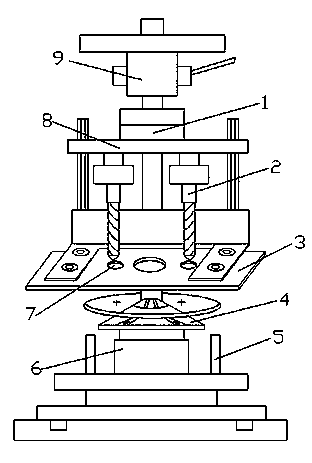

[0016] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

[0017] like figure 1 As shown, a special drilling machine with a center hole for thin plates includes a drilling machine body 9, a tool holder 1 connected to the main shaft is arranged on the drilling machine body 9, a tool holder 8 is connected to the tool holder 1, and a drill bit 2 is installed on the tool holder 8. , the tool holder 8 is provided with a drilling template 3, the drilling template 3 is provided with a die hole 7, the drill bit 2 is arranged directly above the die hole 7, and the lower part of the drill bit 2 is provided with a clamp, which includes a conical circular platform 4, a cone The bottom of the circular platform 4 is provided with a fixed seat 6, which is detachably connected to the conical circular platform 4. The fixed seat 6 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com