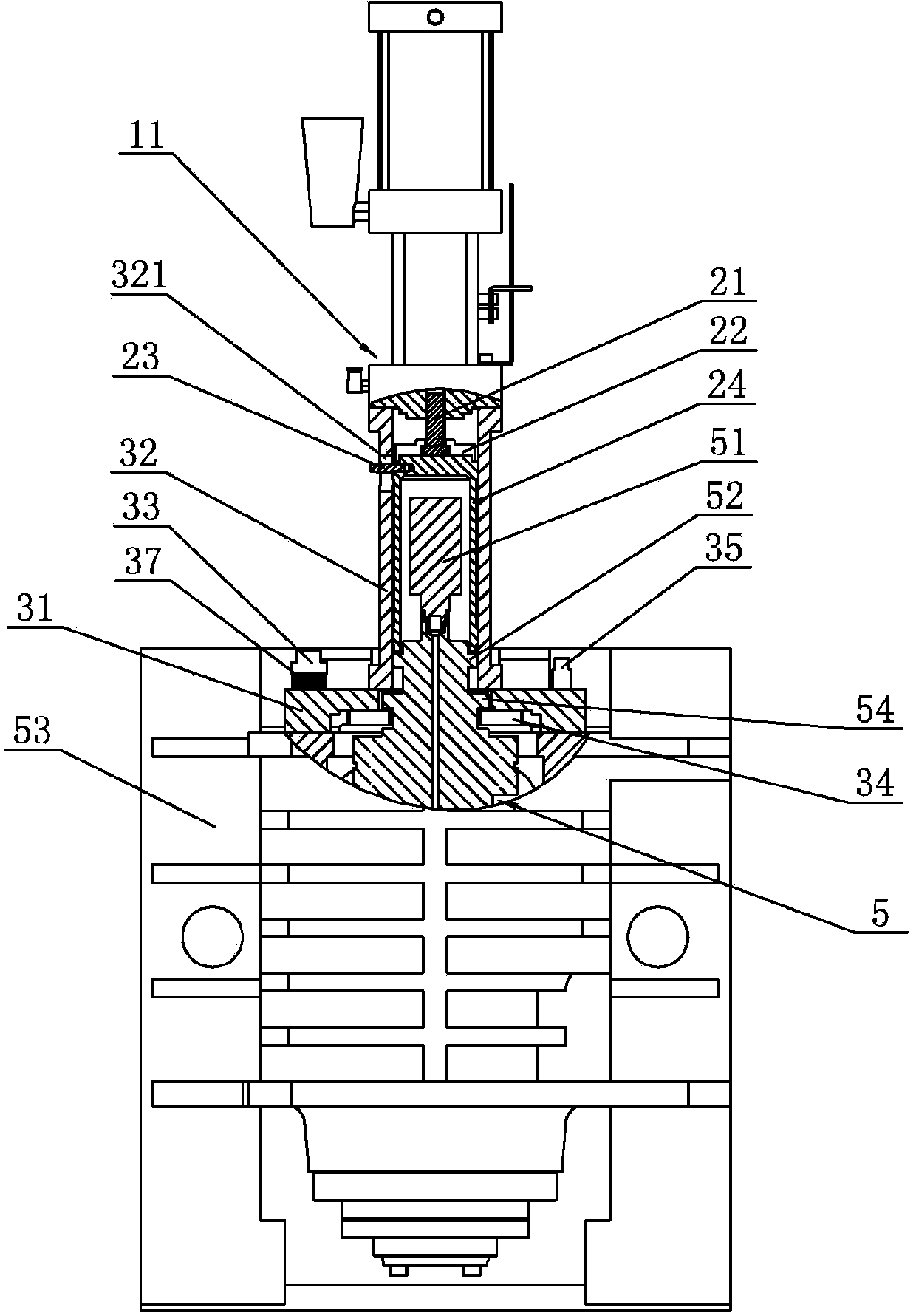

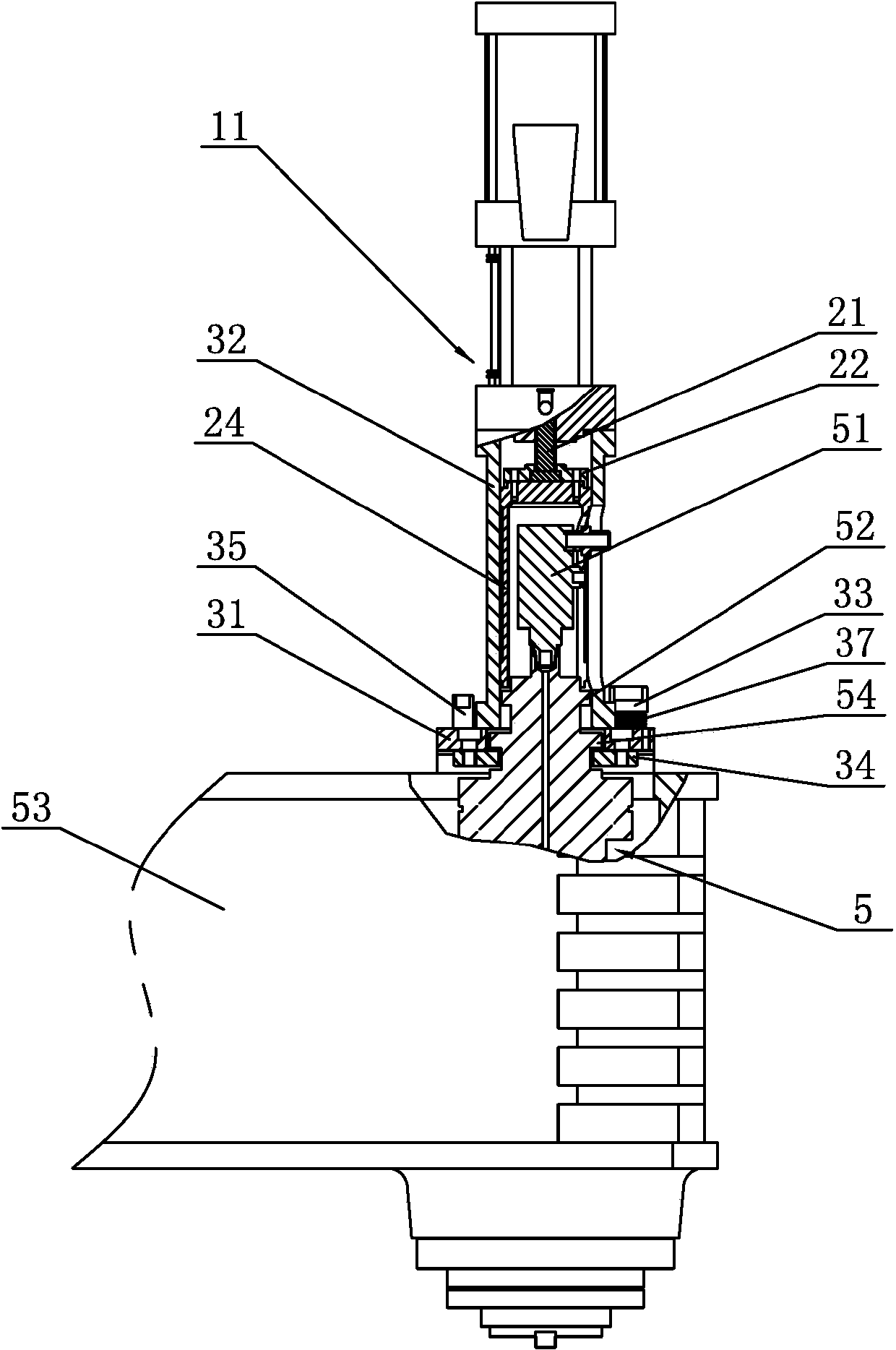

Floating cutter loosening device for central water discharging spindle

A central water outlet and floating technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of spindle bearing damage, cutting coolant leakage, etc., to ensure the degree of automation, improve service life, and improve controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] As shown in the figure, a floating knife release device for the central water outlet spindle includes a gas-hydraulic knife cylinder mechanism for providing power to release the knife, a stroke adjustment mechanism for adjusting the stroke position of the knife release point, and a counteracting mechanism. On the main shaft bearing (not shown in the figure), the floating buckle mechanism of the loosening force, the gas-hydraulic knife cylinder mechanism is arranged above the stroke adjustment mechanism, the gas-hydraulic knife cylinder mechanism is connected with the stroke adjustment mechanism, and the stroke adjustment mechanism It is set above the main shaft loose cutter disc 52, and the floating buckle mechanism is set on the upper end of the main shaft bearing; the gas-hydraulic knife cylinder mechanism includes a gas-hydraulic boos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com