Teaching system based on open type welding robot

A welding robot and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of increasing the difficulty of equipment and software management, increasing the difficulty of equipment maintenance, and the inability of teaching equipment to provide equipment and communication protocol support and other problems, to achieve the effect of teaching function, accurate data transmission, and data transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

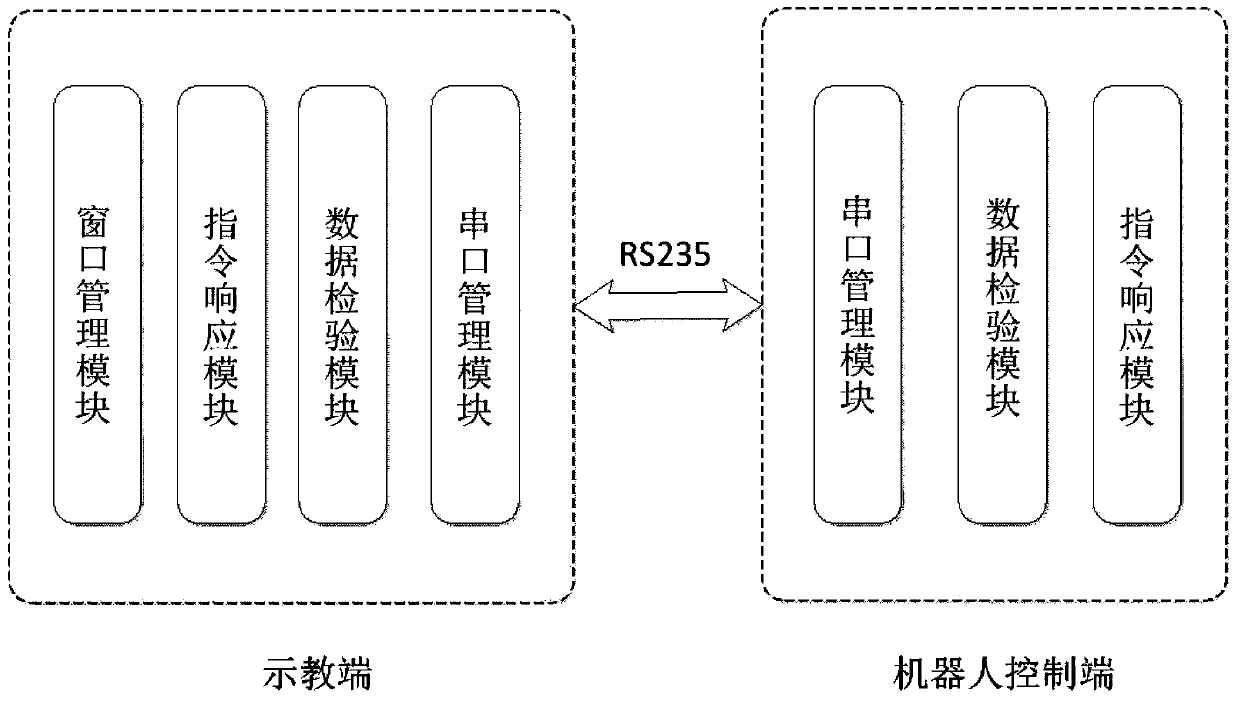

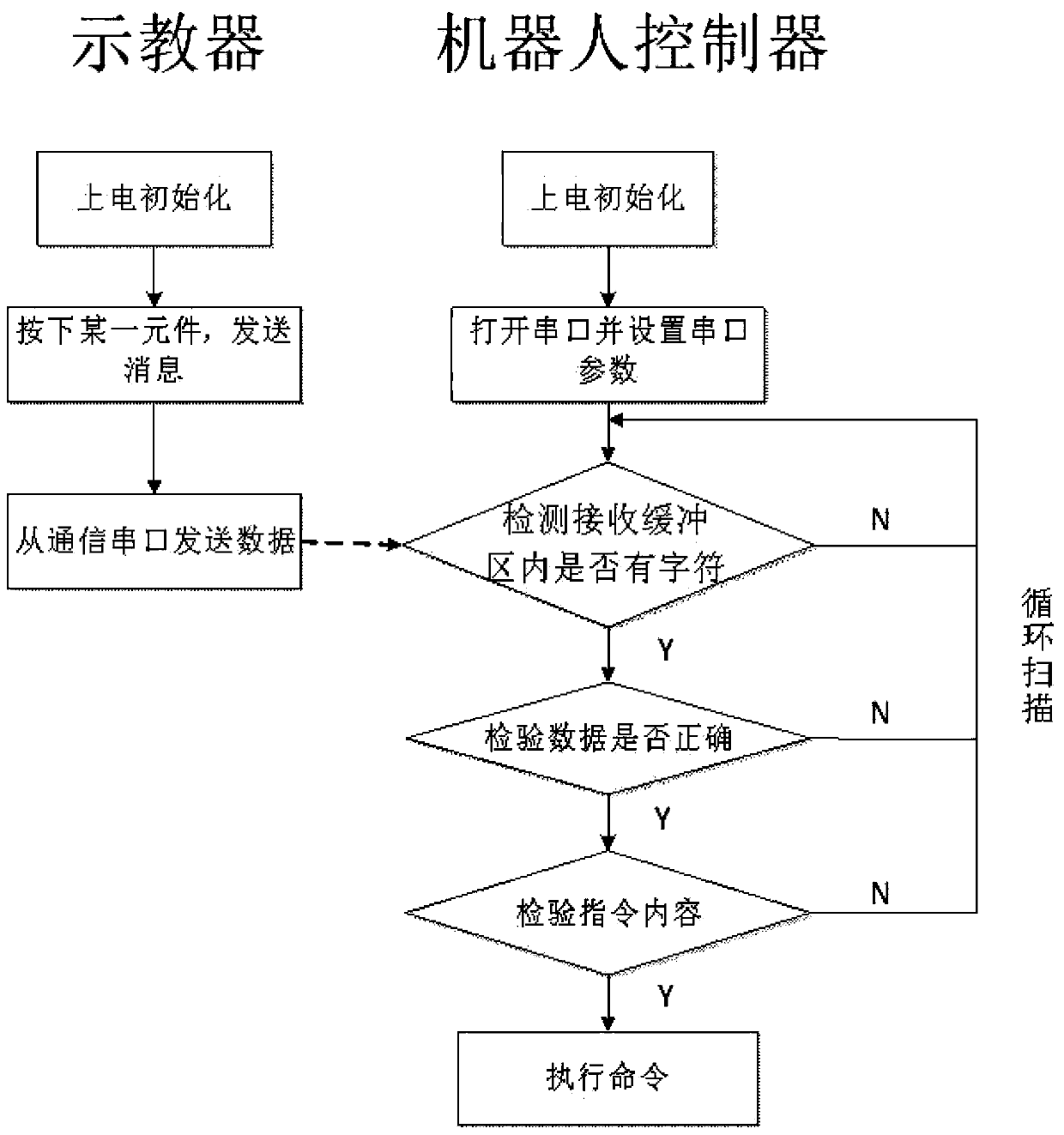

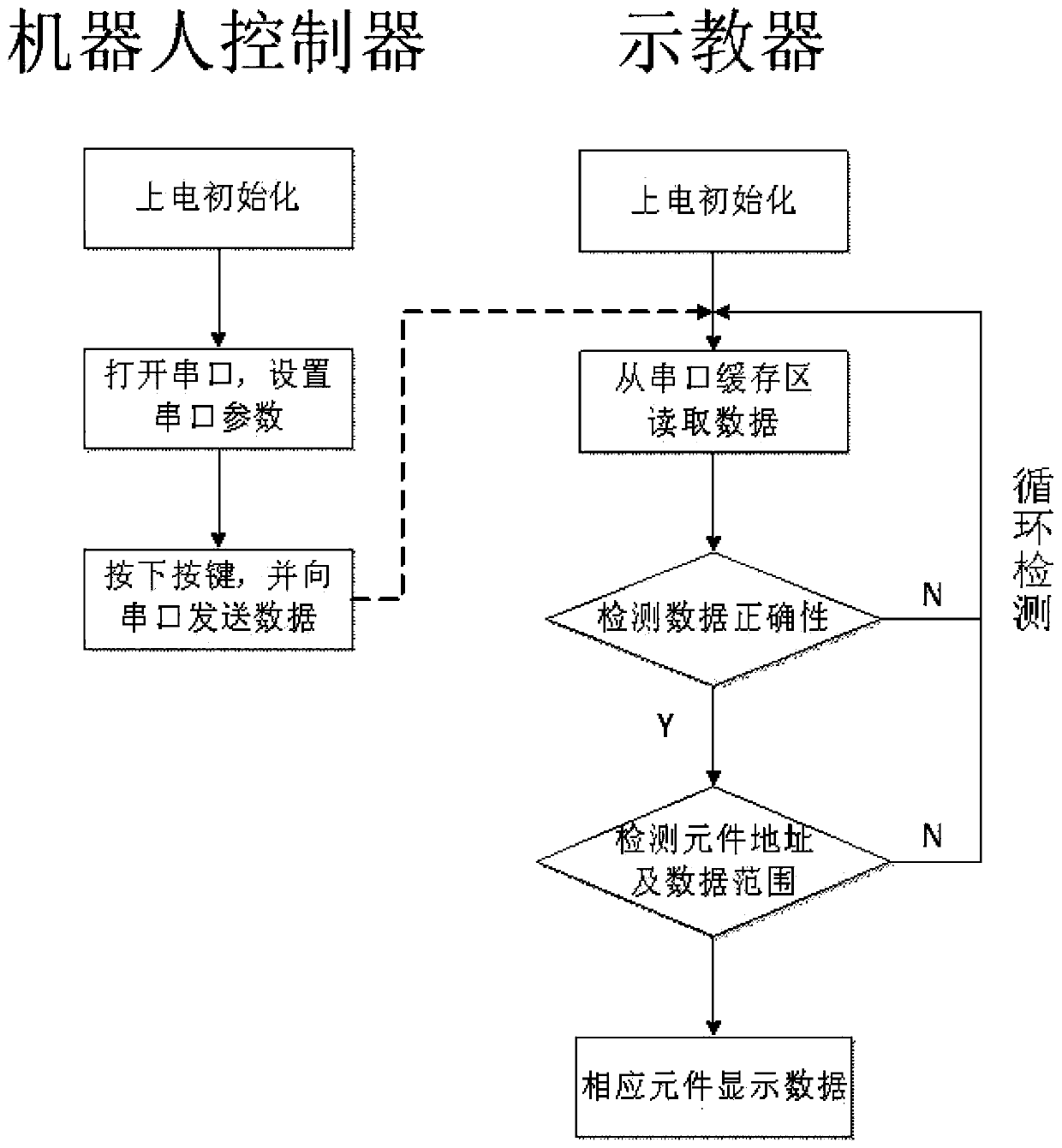

[0048] The technical solution of the invention is mainly aimed at the J-shaped groove welding robot, which is used for welding nuclear power pressure vessels and round pipes. The robot control system uses Advantech's industrial computer IPC-610H as the main controller (robot controller), and the internal configuration is the central processing unit of the Pentium dual-core CPU E5300. The system control software running on the industrial computer chooses to use the MFC basic class library under the Visual C++6.0 environment for programming, and the object-oriented C++ language is used as the programming basic language. The MT6070ih2 model touch screen of Weiluntong brand, a general-purpose human-computer interaction interface HMI product, is used as the hardware of the robot teaching device (teaching device). The touch screen adopts 32Bit RISC 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com