AG functional layer of AG film, AG film, silver nanowire capacitive touch display module and preparation method of silver nanowire capacitive touch display module

A capacitive touch, nano-silver wire technology, applied in chemical instruments and methods, layered products, electrical digital data processing, etc., can solve the problems of not completely replacing key operations, inconvenient transportation and handling, and fragile existence. Achieve the effect of eliminating strong glare, not easy to leave marks, and resisting fingerprint invasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

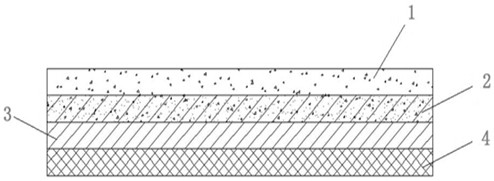

[0054] A nano-silver wire capacitive touch display module consists of an AG film, a nano-silver wire capacitive touch module, a liquid crystal panel, and a backlight module from top to bottom.

[0055] The preparation method is:

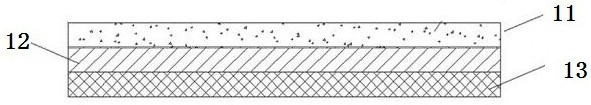

[0056] (1) Preparation of AG film

[0057] The AG functional layer is composed of the following raw materials in terms of weight percentage: 5% of 9-functional urethane acrylate, 10% of 6-functional urethane acrylate, 5% of 2-functional urethane acrylate, 10% of 2-functional reactive diluent, special 2.5% resin, 1% photoinitiator, 0.3% acrylate leveling agent, 0.5% fumed silica, 65.7% solvent, dipropylene glycol diacrylate as difunctional reactive diluent, and 1,6 hexyl leveling agent Glycol diacrylate, the solvent is ethyl acetate, and the functional polyester resin is Zhongshan Qianyou Chemical Materials Co., Ltd. / special functional resin UC7412.

[0058] After the raw materials of the AG functional layer are stirred evenly, they are coated on th...

Embodiment 2

[0070] The AG functional layer is composed of the following raw materials by weight percentage: by weight percentage, the main components are: 7% of 9-functional urethane acrylate, 11% of 6-functional urethane acrylate, 6% of 2-functional urethane acrylate, Bifunctional reactive diluent 13%, special resin 2.5%, photoinitiator 1%, aralkyl modified silicone oil leveling agent 0.3%, fumed silica 0.5%, solvent 58.7%; bifunctional reactive diluent is new Pentylene glycol diacrylate, the photoinitiator is 1-hydroxy-cyclohexyl-phenyl ketone, and the solvent is butyl acetate; the functional polyester resin is Zhongshan Qianyou Chemical Material Co., Ltd. / special functional resin UC7412.

[0071] A method for producing a nano-silver wire capacitive touch display module, comprising the following steps:

[0072] (1) After the raw materials of the AG functional layer are stirred evenly, they are coated on the 250μm thick PET with a bottom layer by dimple coating or slit extrusion coating,...

Embodiment 3

[0082] The AG functional layer is composed of the following raw materials by weight percentage: by weight percentage, the main components are: 5% of 9-functional urethane acrylate, 12% of 6-functional urethane acrylate, 6% of 2-functional urethane acrylate, Bifunctional reactive diluent 11%, special resin 2.5%, photoinitiator 1%, fluorocarbon modified polyacrylate leveling agent 0.3%, fumed silica 0.5%, solvent 61.7%; 2 functional reactive diluent is Propoxylated neopentyl glycol diacrylate, the photoinitiator is diphenyl ketone, the solvent is ethylene glycol monopseudoether, and the functional polyester resin is Zhongshan Qianyou Chemical Materials Co., Ltd. / special functional resin UC7412.

[0083] A method for producing a nano-silver wire capacitive touch display module, comprising the following steps:

[0084] (1) After the raw materials of the AG functional layer are stirred evenly, they are coated on the 250μm thick PET with a bottom layer by dimple coating or slit extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com