Multifunctional thermal protection material and preparation method thereof

A heat protection material and multi-functional technology, applied in separation methods, chemical instruments and methods, metal material coating technology, etc., can solve problems such as corrosion resistance and stealth performance, and improve the ability to resist air erosion, Facilitate long-term storage and prevent oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

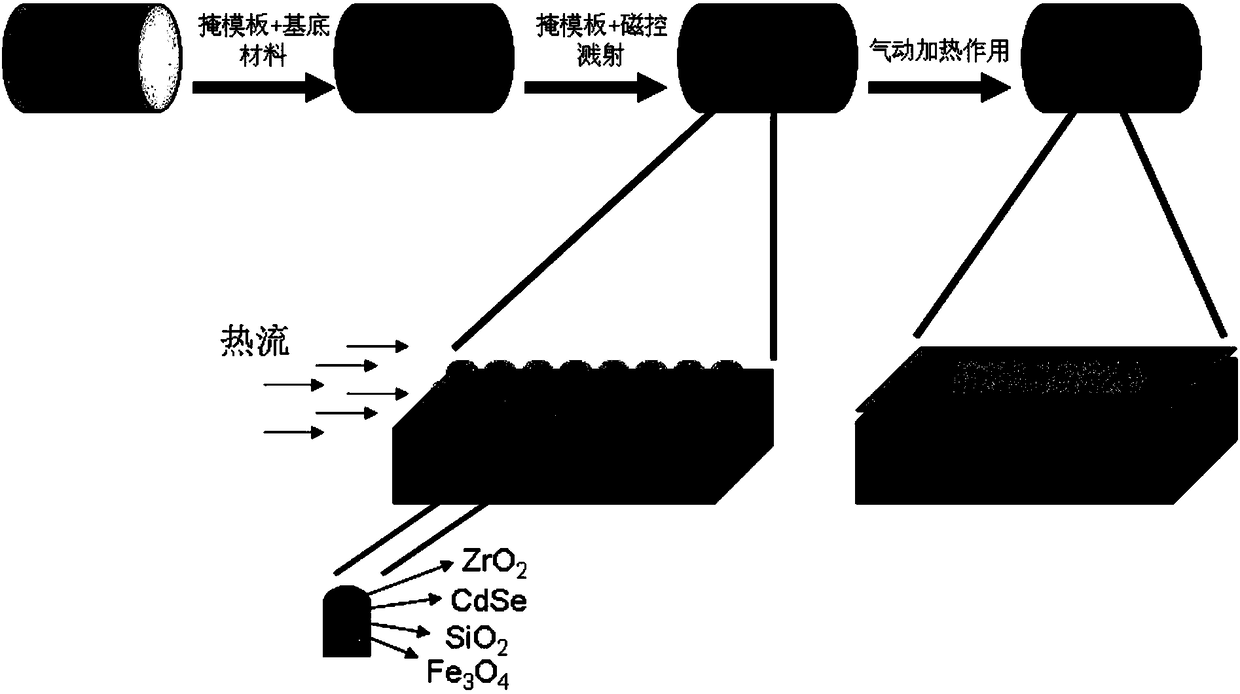

[0051] Such as figure 1 as shown, figure 1 A flow chart of an embodiment of a method for preparing a multifunctional thermal protection material is provided, including:

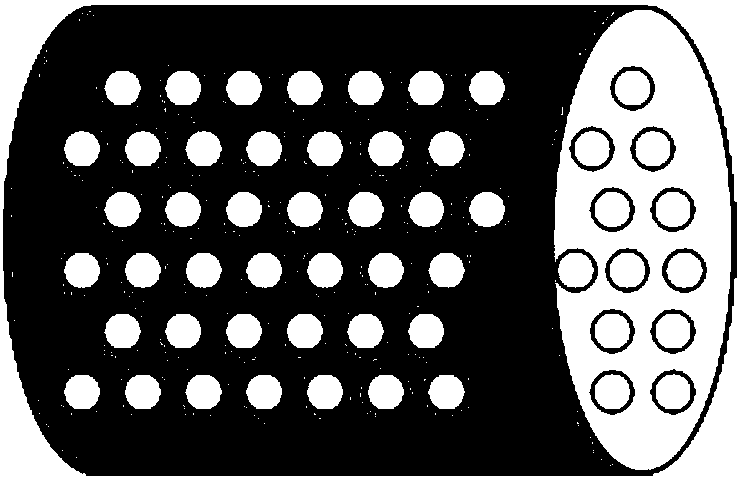

[0052] After the mastoid structure that meets the needs is determined through simulation calculations, the mastoid structure is molded using a periodic mask, specifically: according to the results of the simulation calculation, adaptively design the aperture and arrangement parameters in the mask, Wherein, the aperture size of the mask is adaptively designed based on the bottom layer of the sub-absorbing layer, and the hole arrangement can be designed according to the periodic arrangement of the above-mentioned mastoids; the mask is designed using 3D printing technology get, such as figure 2 shown;

[0053] Based on the above mask, the specific preparation process is as follows:

[0054] Disperse the material used in the bottom sub-absorbing layer in the room temperature curing adhesive;

[0055] Cooper...

Embodiment 1

[0060] In the mastoid structure, the mastoid units arranged in a regular hexagon are arranged periodically. The papillae with a diameter of 500 nanometers are made of 30 nanometer ferric oxide particles mixed with phenolic resin as the bottom layer, and the mastoid units are arranged symmetrically in a regular hexagon. The side length of the hexagon is 800 nanometers. Based on the base layer, a layer of silicon dioxide with a diameter of 1.06 microns in thickness, a layer of chromium selenide with a thickness of 0.78 microns, and a layer of zirconia with a thickness of 8.21 microns are respectively prepared from bottom to top. Its related properties are shown in Table 1. The contact angle of 145° indicates that its surface is superhydrophobic, which can effectively isolate the erosion of water vapor; its normal reflectivity shows that it has a stealth effect on infrared radar in the 1-2 micron band; oxygen-acetylene line ablation The rate of 0.06mm / s shows that the nanostructur...

Embodiment 2

[0064] In the mastoid structure, the mastoid units arranged in a regular quadrilateral are arranged periodically. The papillae with a diameter of 1 micron are made of 100 nanometer ferric oxide particles mixed with phenolic resin as the bottom layer. The mastoid units are arranged symmetrically in a regular quadrilateral, and the side length of the quadrilateral 1.5 microns, based on the base layer, a layer of silicon dioxide with a diameter of 1.86 microns, zinc selenide with a thickness of 1.56 microns, and zirconia with a thickness of 10 microns were prepared from bottom to top. Its related properties are shown in Table 2. The contact angle of 137° indicates that its surface is superhydrophobic, which can effectively isolate the erosion of water vapor; its normal reflectance indicates that it has a stealth effect on the far-infrared radar in the 10.6 micron band; the oxygen-acetylene line ablation rate of 0.02mm / s indicates that the nanometer The structure has anti-ablation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com