Rubber and plastic alloy asphalt modifier

A technology of asphalt modifier and rubber-plastic alloy, applied in the field of asphalt modification, can solve the problems of unreachable, high cost, loss of modification effect, etc., and achieve the effect of increasing high temperature strength, reducing cost and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

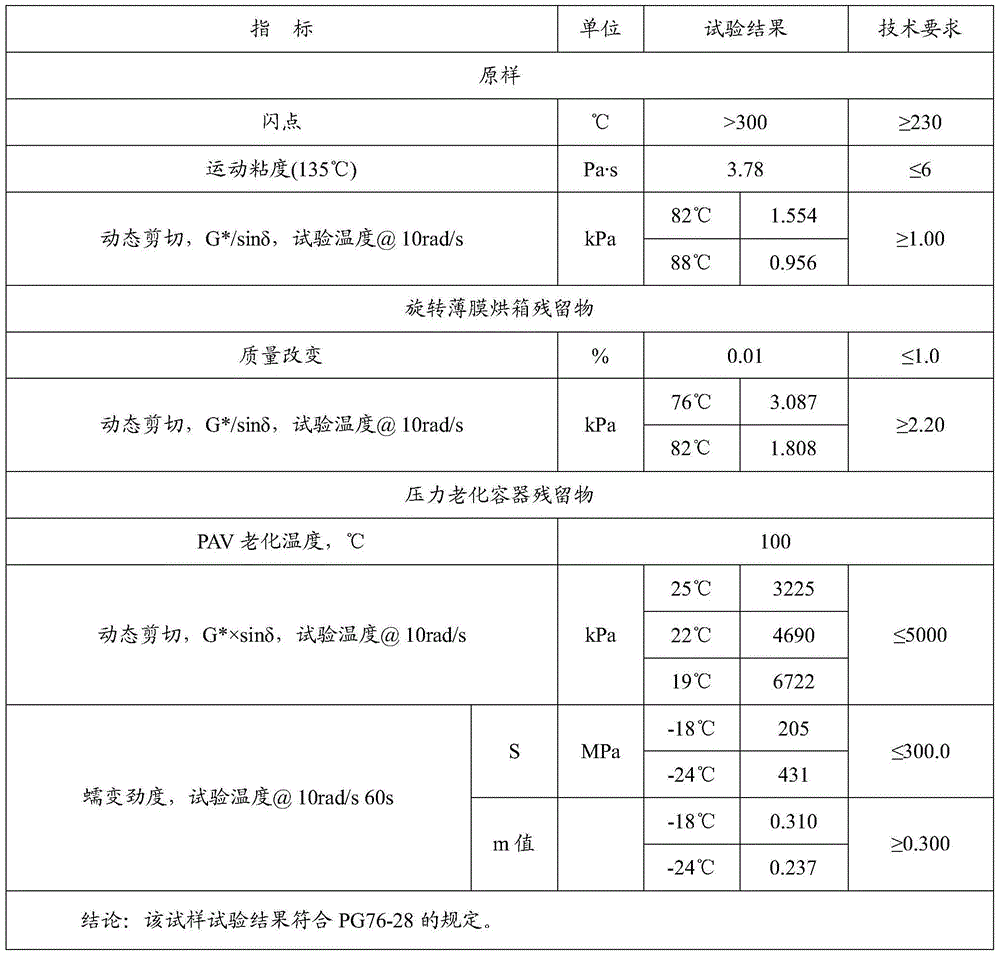

Examples

Embodiment 1

[0028] A rubber-plastic alloy asphalt modifier, its main composition and parts by weight: 65 parts of waste tire rubber powder, 25 parts of waste plastic particles, 2 parts of plasticizer, 0.2 part of surfactant;

[0029] Wherein said waste tire rubber powder is 20 mesh waste radial tire crushed rubber powder; said waste plastic particles are selected from crushed waste plastic particles with a PE component greater than 80wt%; all are purchased directly from the market;

[0030] The plasticizer is selected from epoxy fatty acid methyl ester; the surfactant is selected from FLUORAD FC-430.

[0031] The specific preparation steps are as follows: heating waste tire rubber powder to 230-250° C. on a single-screw machine, adding plasticizer epoxy fatty acid methyl ester, maintaining the rubber powder at 230-250° C. to soften and degrade the rubber powder for 20-30 minutes, and then Add surfactant and waste plastic granules in sequence, run the above-mentioned blend twice on the scr...

Embodiment 2

[0049] A rubber-plastic alloy asphalt modifier, its main composition and parts by weight: 73 parts of waste tire rubber powder, 30 parts of waste plastic particles, 5 parts of plasticizer, and 0.6 part of surfactant;

[0050] Wherein said waste tire rubber powder is the crushed rubber powder of 40-mesh waste bias tire; said waste plastic particles are selected from the crushed particles of waste plastics with a PE component greater than 80wt%; all are purchased directly from the market;

[0051] The plasticizer is selected from epoxy fatty acid methyl ester; the surfactant is selected from FLUORADFC-430.

[0052] The specific steps are as follows:

[0053] Heat waste tire rubber powder to 230-250°C on a single-screw machine, add plasticizer epoxy fatty acid methyl ester, maintain the temperature at 230-250°C to soften and degrade the rubber powder for 20-30 minutes, and then add surfactants in sequence, For waste plastic granules, the above-mentioned blend is run twice on a s...

Embodiment 3

[0061] A rubber-plastic alloy asphalt modifier, its main composition and parts by weight: 72 parts of waste tire rubber powder, 25 parts of waste plastic particles, 2.7 parts of plasticizer, and 0.3 part of surfactant;

[0062] Wherein said waste tire rubber powder is the crushed rubber powder of 30 purpose waste radial tires and bias tires; the waste plastic particles are selected from the crushed particles of waste plastics whose PE composition is greater than 80wt%; all from the market purchased directly;

[0063] The plasticizer is selected from epoxy fatty acid methyl ester; the surfactant is selected from FLUORADFC-430.

[0064] The specific steps are as follows:

[0065] Heat waste tire rubber powder to 230-250°C on a single-screw machine, add plasticizer epoxy fatty acid methyl ester, maintain the temperature at 230-250°C to soften and degrade the rubber powder for 20-30 minutes, and then add surfactants in sequence, For waste plastic granules, the above-mentioned bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com