Palm fiber reinforced soil, preparation method thereof and application

A technology of palm fiber and reinforced soil, which is applied in excavation, soil protection, construction, etc., to achieve the effect of low cost, good reinforcement performance, and improved unconfined compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

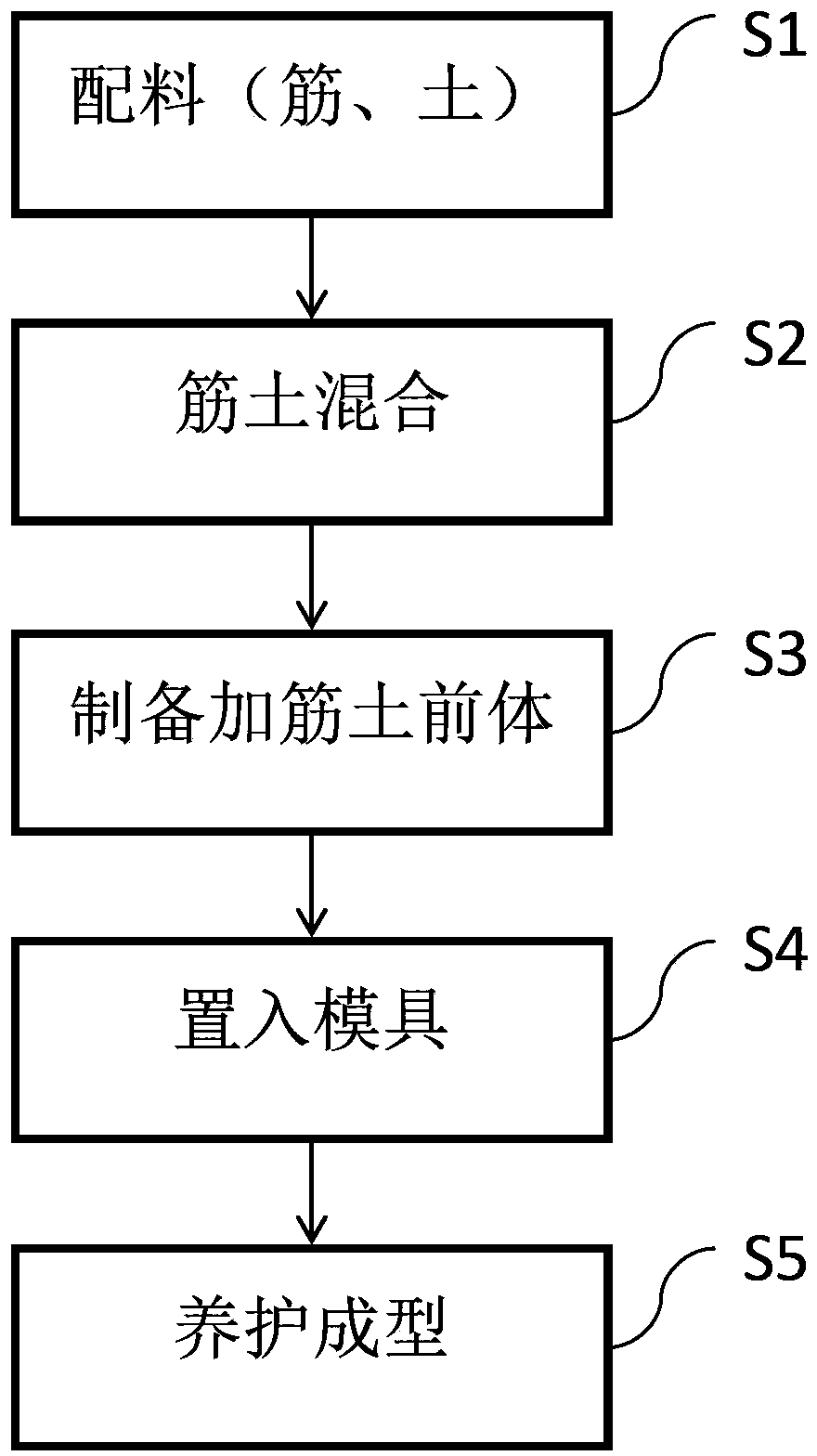

[0015] attached figure 1 It is a flowchart of the preparation method of palm fiber reinforced soil of the present invention.

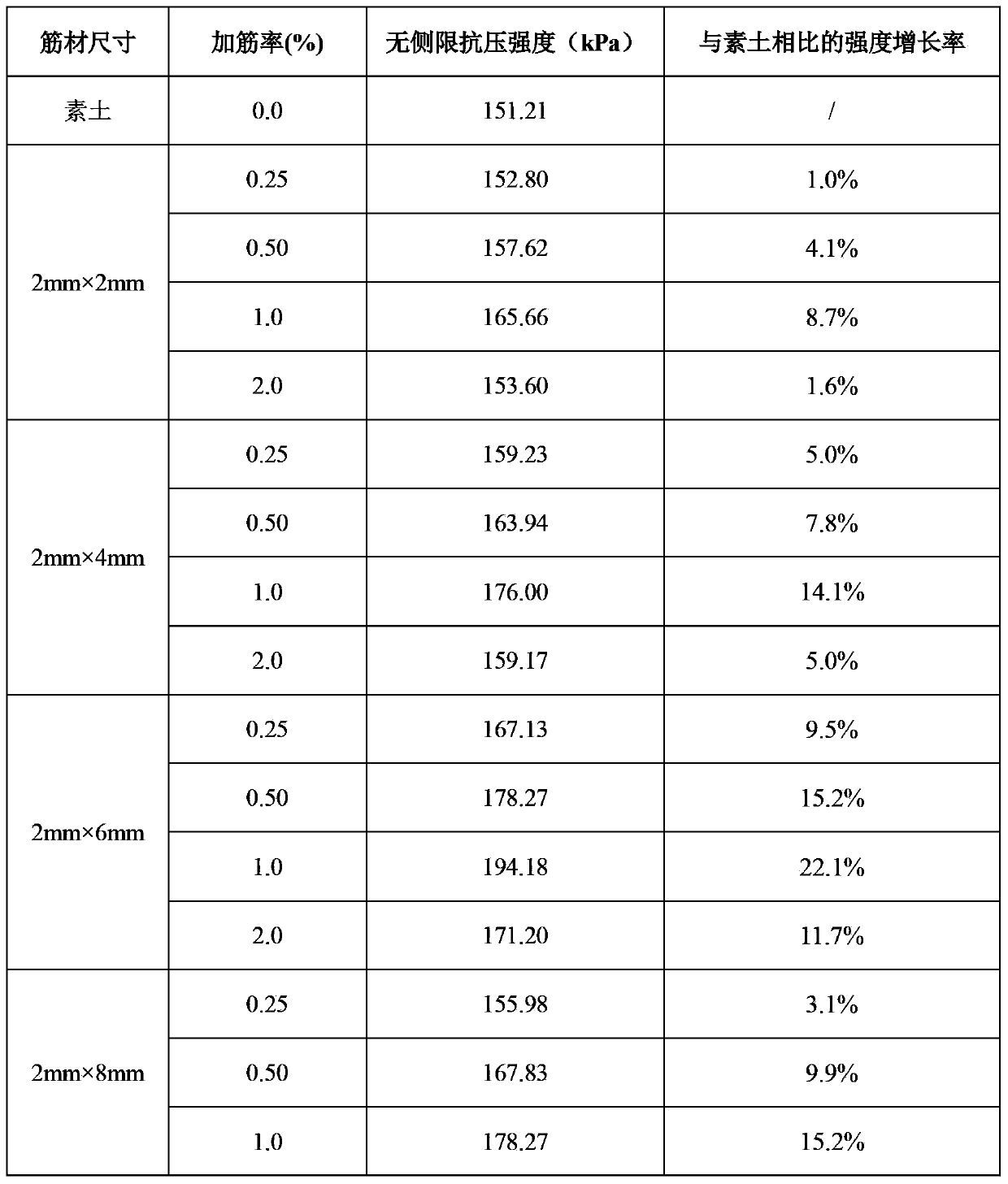

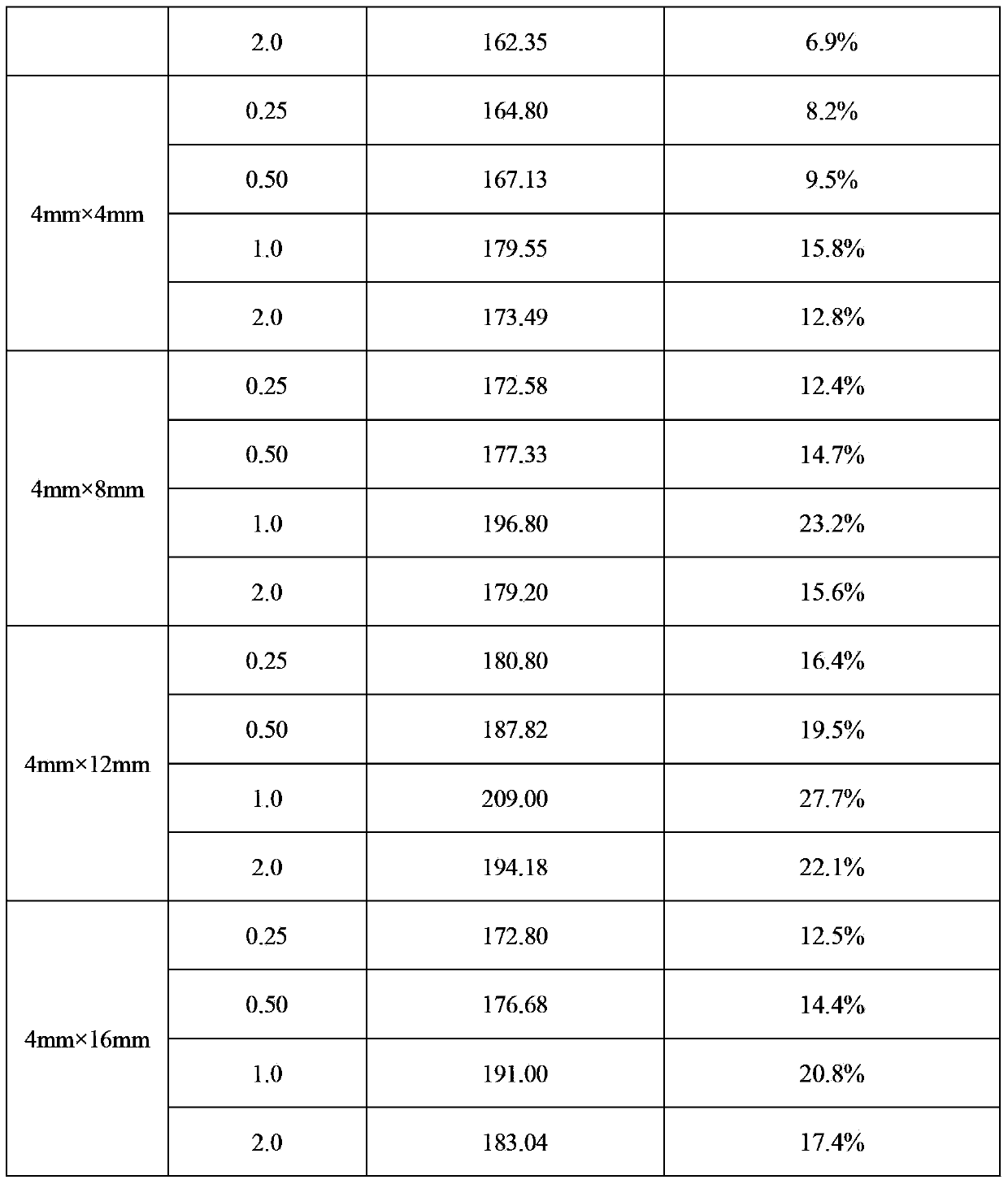

[0016] As shown in the figure, first carry out batching S1, process the soil and palm fiber into the state required by the process, and mix them in a certain proportion. The soil (maximum dry density 1.62g / cm2) will be taken from the underground of Zhangjiang Science and Technology Park in Pudong, Shanghai about 3 to 5 meters 3 , plastic limit moisture content 20.56%, liquid limit moisture content 42.34%, plasticity index 21.78) air-dried under natural conditions, crushed, and then passed through a 2mm geotechnical sieve, each group of tests weighed 5000g of dry soil; processed palm fiber separately 2mm×2mm, 2mm×4mm, 2mm×6mm, 2mm×8mm, 4mm×8mm, 4mm×4mm, 4mm×8mm and 4mm×16mm, a total of 8 different sizes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com