Hydraulic damper with adjustable damping

A hydraulic shock absorber and damping technology, which is applied in the field of hydraulic shock absorbers, can solve problems such as low service life, complex structure, and unstable shock absorber performance, and achieve the effects of low requirements, improved comfort, and easy maintenance and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

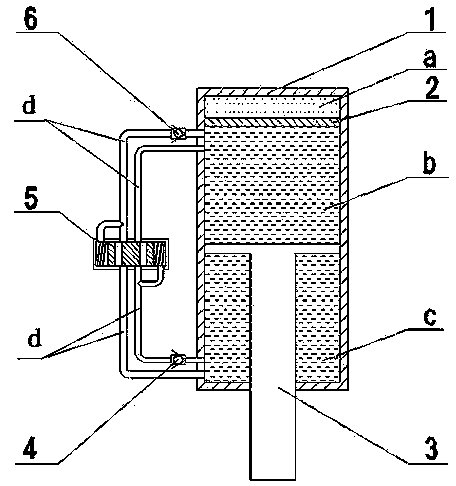

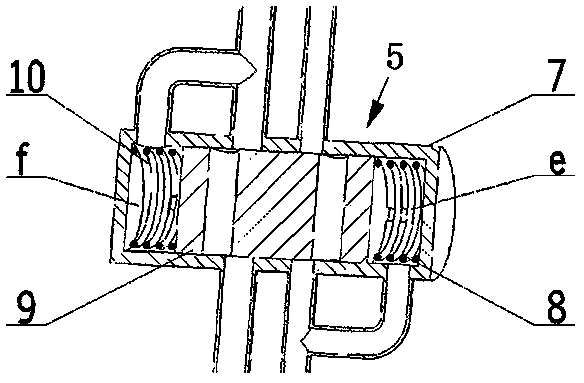

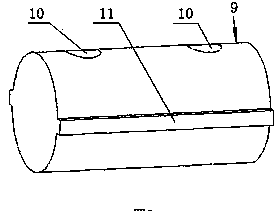

[0016] Such as figure 1 As shown, the shock absorber with adjustable damping of the present invention includes a cylinder 1 , a floating piston 2 and a piston 3 . Wherein the floating piston 2 is in the cylinder body 1, is located at the top of the piston 3, and is in sealing contact with the inner wall of the cylinder body 1. The piston rod at the bottom of the piston 3 protrudes from the bottom of the cylinder 1 to the outside of the cylinder 1, and the piston 3 has a 1mm through hole, and the top of the piston 3 is in sealing contact with the inner wall of the cylinder 1. The floating piston 2 and the piston 3 divide the cylinder body 1 into three chambers, namely the upper compressed air chamber a, the middle upper oil chamber b and the lower lower oil chamber c. The compressed air chamber a is used to compensate for the reduction of the oil storage volume of the cylinder 1 due to the upward movement of the piston 3 (compression stroke) into the cylinder 1. Outside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com