LED lamp heat dissipation structure and LED energy-saving lamp with same

A technology for LED lamps and heat dissipation structures, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc. Short and other problems, to achieve the effect of convenient and fast installation, disassembly and maintenance operations, improve power and service life, work stability of LED lights, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

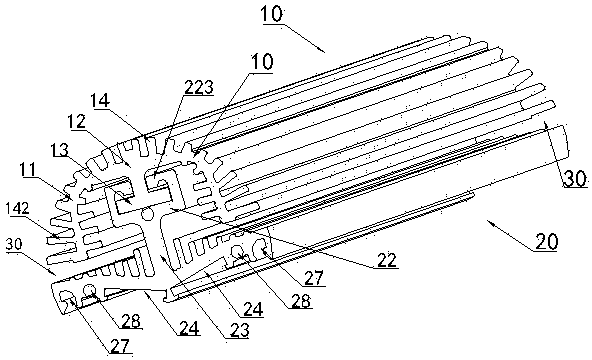

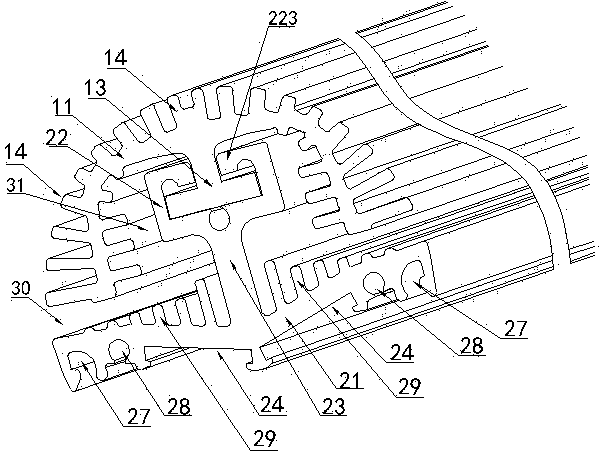

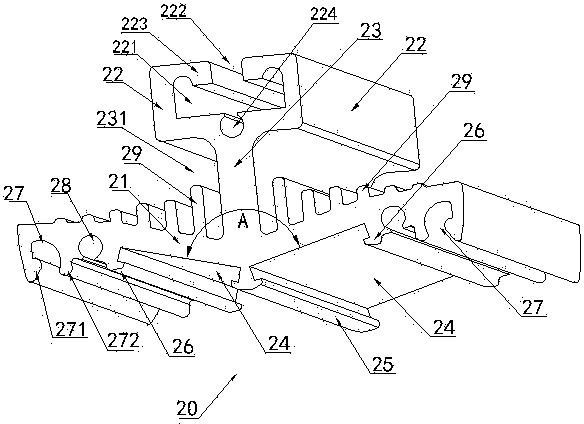

[0024] figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment, a heat dissipation structure of an LED lamp includes a first heat dissipation member 10 and a second heat dissipation member 20, wherein the first heat dissipation member 10 is the outer heat dissipation member of the LED lamp heat dissipation structure, and the second heat dissipation member 20 is an LED The inner heat dissipation member of the lamp heat dissipation structure, the inner surface of the second heat dissipation member 20 is provided with an LED chip mounting groove 24 for installing LED chips; the outer surface of the second heat dissipation member 20 is connected with a plurality of protruding second heat dissipation The fins 29 are connected with the first heat dissipation member 10 on the outer side of the second heat dissipation member 20, and the first heat dissipation member main body 11 of the first heat dissipation member 10 is a symmetrical arc-shaped body placed upside down ...

Embodiment 2

[0026] Figure 6 In the illustrated embodiment, the first heat dissipation member 10 and the second heat dissipation member 20 are integrally formed with each other, and there is a gap between the inner top of the first heat dissipation member 10 and the outer middle part of the second heat dissipation member 20. The connecting straight arm 123 connecting the first heat dissipation member 10 and the second heat dissipation member 20 (see Figure 6), directly connect the first heat dissipation member 10 and the second heat dissipation member 20 of the inverted U-shaped body by connecting the straight arm 123 to form an integrally formed inner and outer heat dissipation structure, and the others are the same as the first embodiment. The air flow at the inner groove of the first heat dissipation member 10 can be increased, so that the heat generated after the LED chip heats up can quickly reach radiation and convection into the air, so as to effectively improve the evacuation eff...

Embodiment 3

[0028] Figure 5 In the shown embodiment, an LED energy-saving lamp includes an LED lamp diffuser cover 50 and a power input control box 30, and adopts the LED lamp heat dissipation structure described in Embodiment 1 or Embodiment 2. After the fastening block 51 on the LED light diffusion cover 50 is fastened to the fastening slot 27 on the LED light diffusion cover 50, a power input control box 30 with a power plug is installed at the front end, and a tail end cover 40 is installed at the rear end. 1. The LED lamp diffusion cover 50 and the LED lamp heat dissipation structure formed by the connection of the first heat dissipation member 10 and the second heat dissipation member 20 are assembled into an LED energy-saving lamp, and the others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com