Straight-through vacuum heat collecting element with variable-vacuum-degree idle sunning protection

A technology of vacuum heat collection and vacuum degree, which is applied in heating devices, solar thermal devices, solar thermal power generation, etc., and can solve problems such as high difficulty in bridging and blockage of spring glass tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

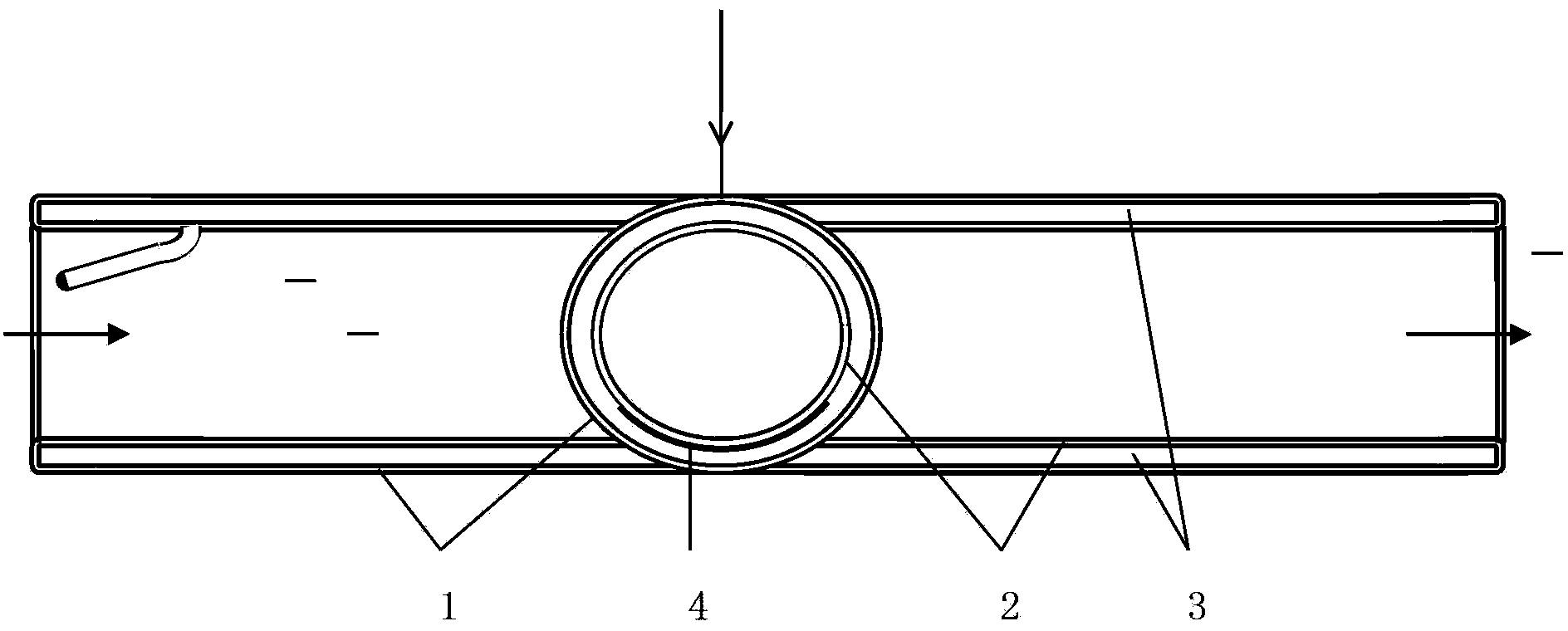

[0012] figure 1 An example of the present invention is given.

[0013] figure 1 In the process, the cover glass tube 1 and the inner glass tube 2 are concentrically embedded and installed, and the two ports are aligned and melted to form a jacket, and the interlayer of the jacket is evacuated to form a vacuum insulation layer 3; the inner glass tube 2 Deposit selective absorption film; on the non-light-facing surface of the inner glass tube 2 at a circumferential angle of about 140 degrees, a piece of activated carbon fiber adsorption material 4 with a length of about 200 mm is connected with a steel wire circlip with low thermal resistance to form a variable vacuum degree Air drying protects straight-through vacuum heat collecting elements.

[0014] figure 1 Working principle of the embodiment: sunlight passes through the cover glass tube 1 and is converted into heat energy on the film layer of the inner glass tube 2, and the heat energy is transferred to the water in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com