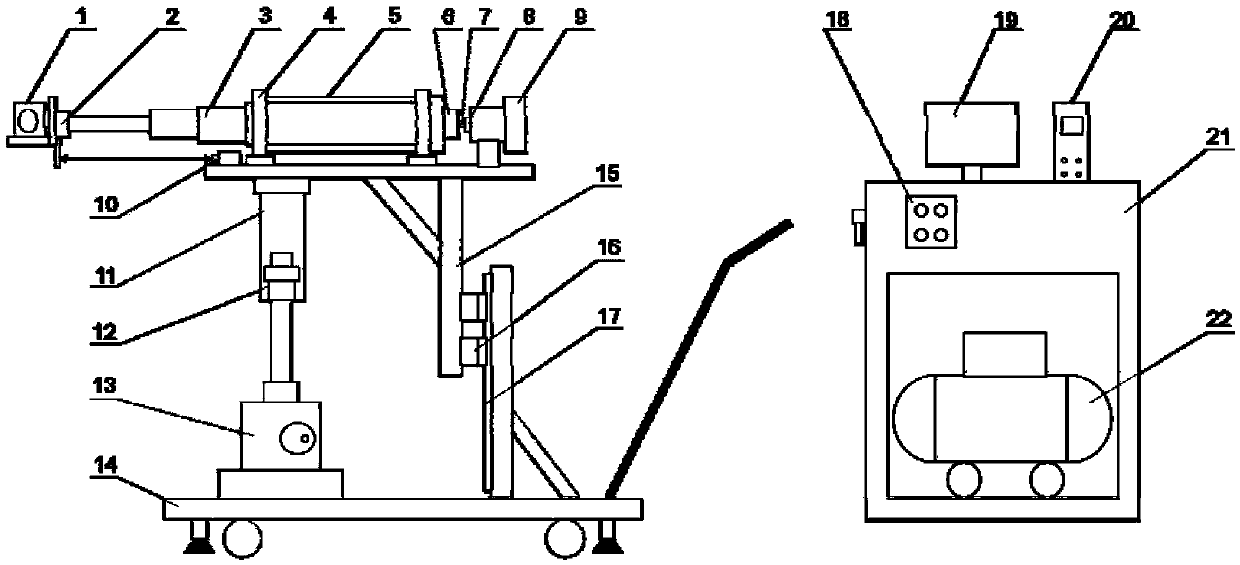

Image collection device for internal surface of long straight pipe

An image acquisition equipment and inner surface technology, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of image acquisition on the inner surface of straight pipes with low degree of automation, and achieve reliable performance, high positioning accuracy, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

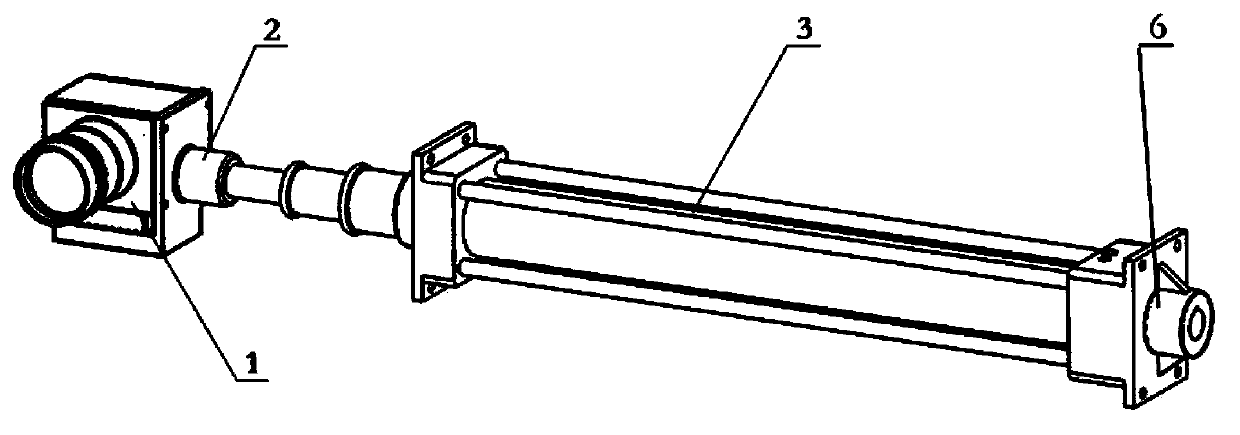

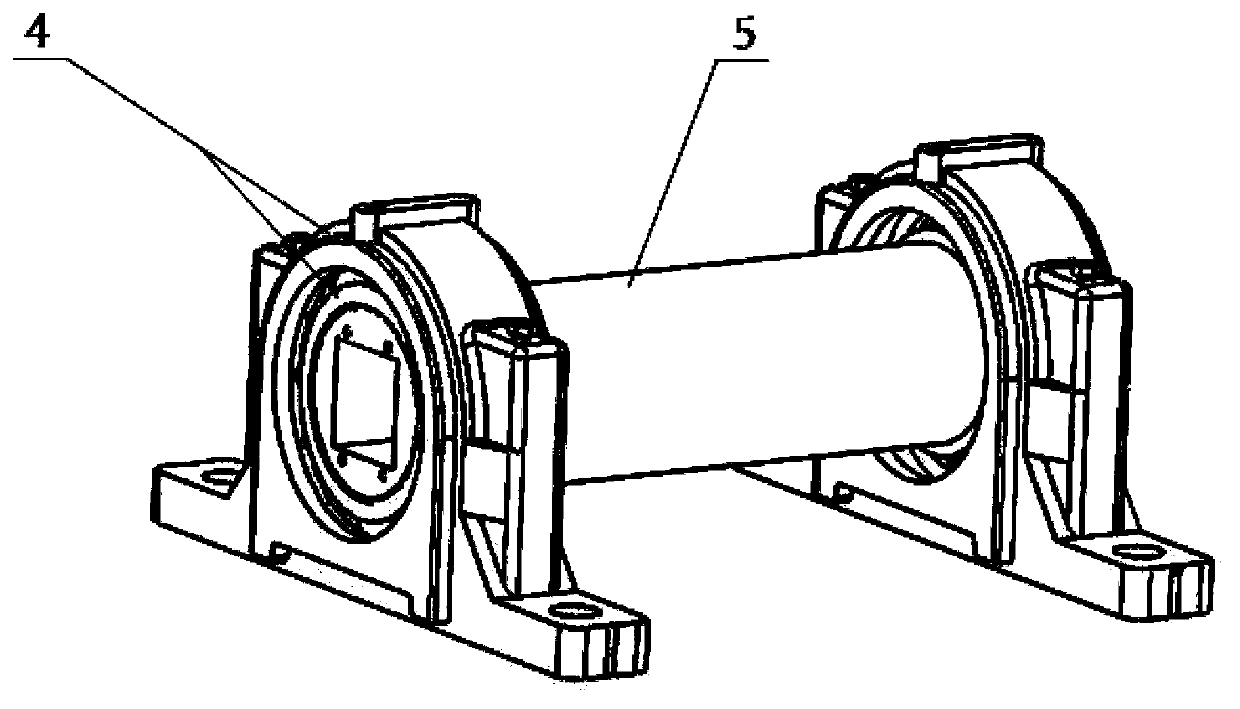

[0020] In this embodiment, the industrial camera 1 is fixed on the camera bracket 2, and then installed on the end of the cylinder rod of the three-stage cylinder 3 through threaded connection. The three-stage cylinder 3 is fixed in the stepped hollow air cylinder shaft 5, and the stepped hollow air cylinder The sleeve shaft is packed into a pair of rolling bearings and installed in the bearing housing 4. The cylinder connecting accessory 6 at the tail end of the three-stage cylinder utilizes a flat key to connect with the short shaft 7, and the short shaft links to each other with the servo motor 9 through a coupling 8. Driven by the servo motor, the three-stage cylinder 3 and the industrial camera 1 can rotate 360 degrees around the central axis of the inner wall, and the three-stage cylinder can drive the industrial camera to achieve a certain length of free expansion and contraction. The three-stage cylinder 3 uses a silent air pump 22 as an air source, adopts two-way sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com