A wheel hub detection system and detection method based on X-ray

An X-ray and hub technology, applied in the field of automatic selection system, can solve the problems of inability to perform automatic detection, poor stability, cumbersome operation, etc., and achieve the effects of stable control parameters of the ray source, high adjustment efficiency, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

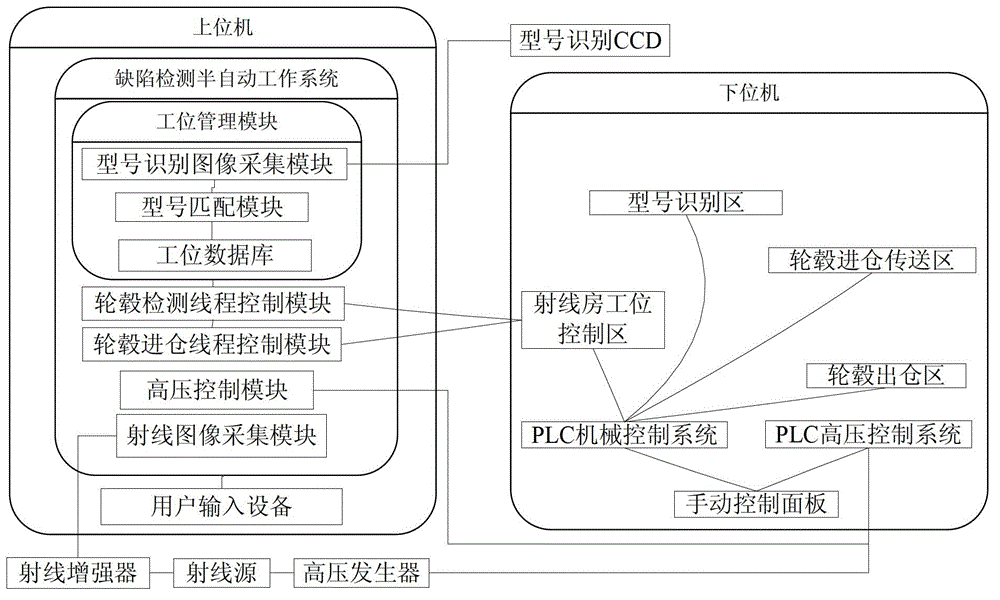

[0042] Such as figure 1 As shown, the defect detection semi-automatic working system includes a high-voltage control module, a radiographic image acquisition module, a station management module, a wheel hub warehouse entry thread control module, and a wheel hub detection thread control module. The station management module includes a model recognition image acquisition module , station database and model matching module. The host computer is sequentially connected to the ray intensifier, the radiation source, the high voltage generator and the lower computer through connecting wires, and the CCD image sensor and the upper computer are separately connected to the upper computer through connecting wires. The hub entry thread control module and the hub detection thread control module are connected to the PLC mechanical control system, and the high voltage control module is connected to the PLC high voltage control system.

[0043] The above-mentioned upper computer also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com