Device for measuring suspended load sand content through specific heat capacity method in non-contact mode

A non-contact measurement and sediment content technology, which is applied in the field of suspended sediment content measurement to achieve the effect of good real-time measurement, reliable measurement instrument and simplified measurement work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

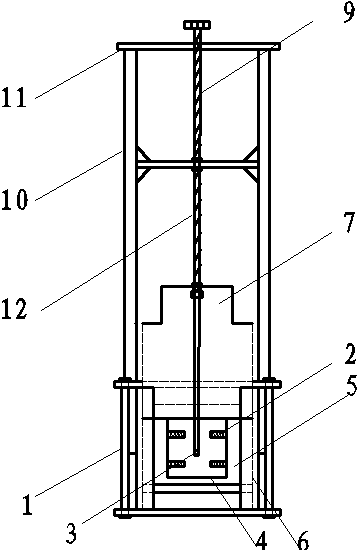

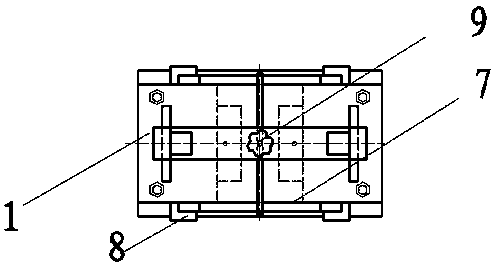

[0013] The specific implementation manner of the invention will be further described below in conjunction with the accompanying drawings.

[0014] After the device reaches the designated water area, such as figure 1 The sampling heater 1 is placed in a designated water area by the expansion and contraction height of the sampling expansion rod 10 . Lifting the gate switch handle 9 lifts the water inlet and outlet gate 7 and slides the gate groove 8 along the gate, so that the external water sample enters. Put down the gate switch handle 9 and close the water inlet and outlet gate 7 after the water inlet is completed, and the external water sample stops entering, and the sampling is completed. The start-up control shows that the single-chip microcomputer 11 uses the heating resistance wire 2 to heat the internal water sample. At this time, the sampling heater heat insulating layer 5 between the sampling heater inner wall 4 and the sampling heater outer wall 6 plays a role of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com