Fault detection method for Hall position sensors

A technology of sensor failure and Hall position, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of simple detection method and low reliability, and achieve the effect of low optimization cost, good effect, and low false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a fault detection method of a Hall position sensor.

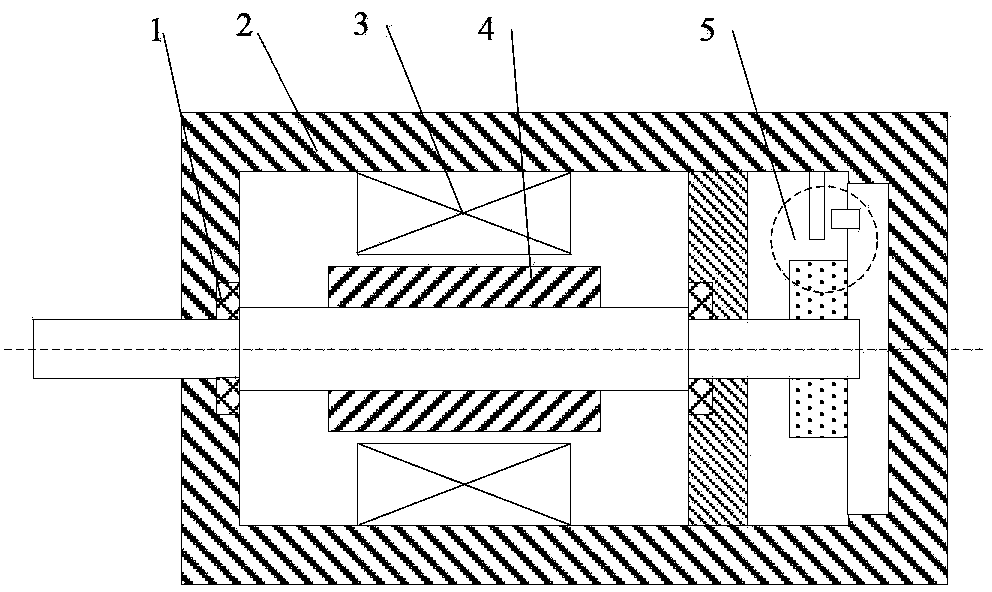

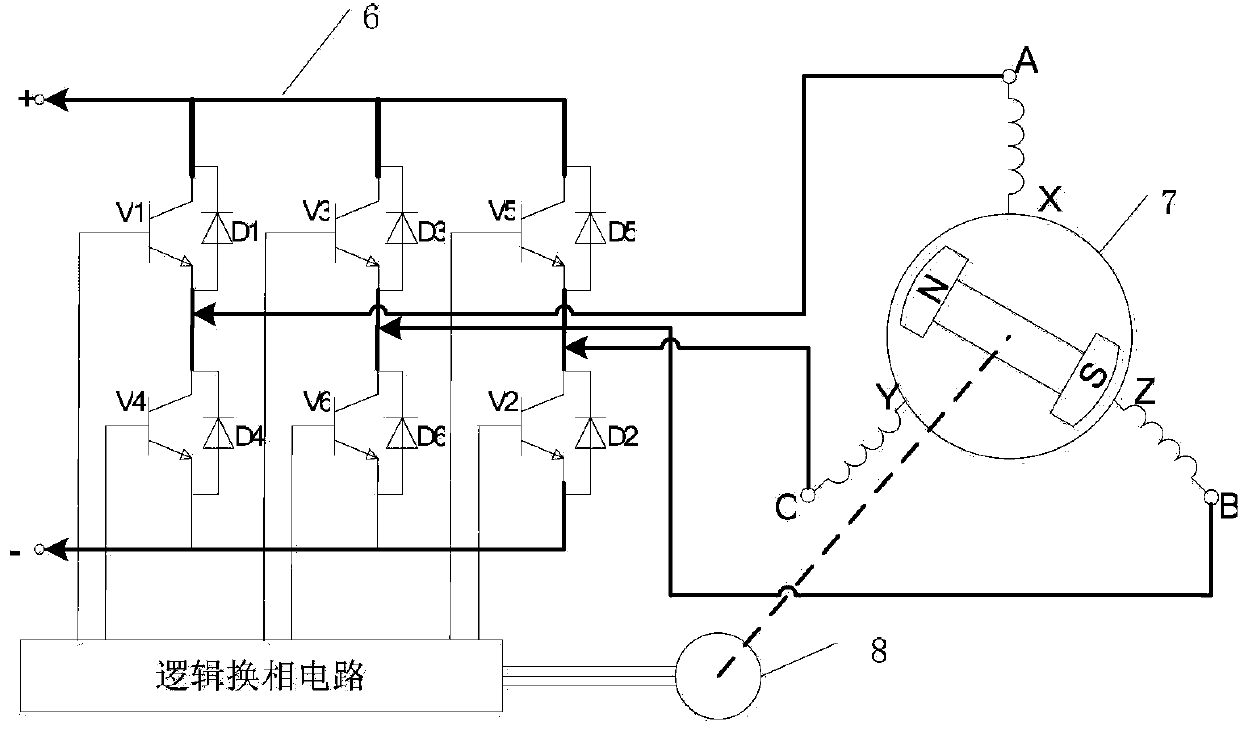

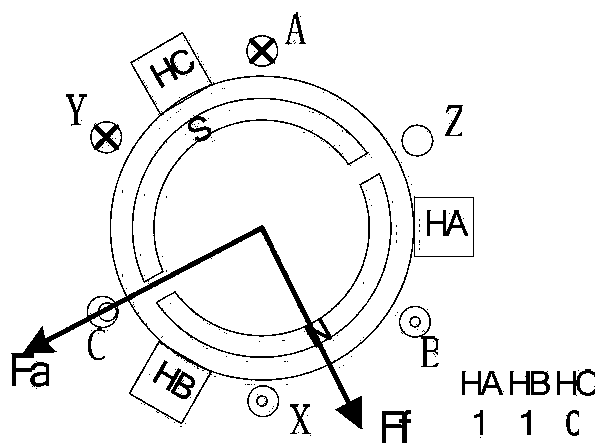

[0029] refer to figure 1 , figure 2 , figure 1 It is a structural schematic diagram of a brushless DC motor. It can be seen from the figure that the position sensor is located inside the motor body, which is easily affected by strong magnetic fields and vibrations, and is prone to failure. The control system of the brushless DC motor adopts a three-phase full-bridge structure, such as figure 2 As shown, T1-T6 are power switch tubes, and D1-D6 are freewheeling diodes. Using this topology, different magnetic potentials can be generated through different switch combinations to drive the motor to rotate. The commutation process of the brushless DC motor and the corresponding Hall switch state are as follows: Figure 3-a~Figure 3-f shown.

[0030] In this embodiment, TMS320F2812 is used as the main control chip, IR2130 is used as the driving chip, and a three-phase bridge inverter circuit and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com