Passive driving electrophoretype electronic paper device

An electronic paper and electrophoresis technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem that the background electrode display is difficult to achieve high-definition patterns, the circuit board accuracy is difficult to meet the requirements of Chinese character display, and the cost of printed circuit boards is high. problems, to achieve the effect of flexible choice of driving mode, fine display pattern, low processing technology and equipment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

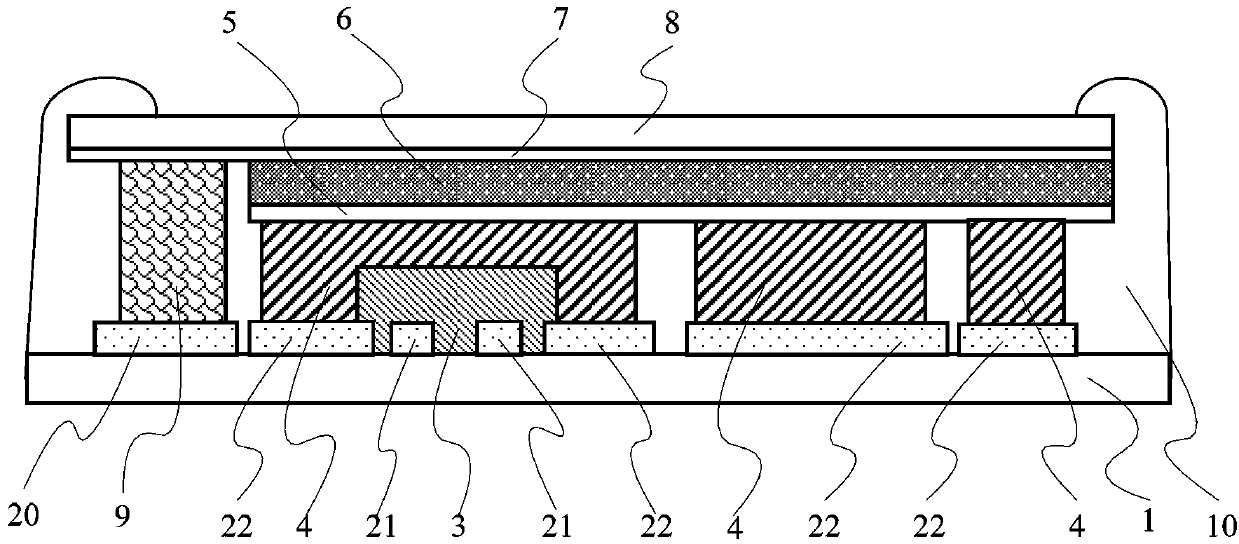

[0022] Such as figure 1 A passively driven electrophoretic electronic paper device shown includes: a display medium layer 6 and an upper substrate 8 and a lower substrate 1 oppositely arranged; a first electrode is formed on the upper surface of the lower substrate 1; the first electrode includes The common lead electrode 20, the display lead electrode 21 and the display electrode 22; the common electrode 7 is formed on the lower surface of the upper substrate 8; the common electrode 7 is electrically connected to the common lead electrode 20 through the transfer electrode 9; the display lead electrode 21 Covered with an insulating layer 3; the second electrode 4 is formed on the display electrode 22 and the insulating layer 3; the display lead electrode 21 is electrically connected to the display electrode 22; the display electrode 22 is connected to the second electrode 4 is electrically connected; the display medium layer 6 is accommodated between the common electrode 7 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com