Method and device for controlling cold-bending forming production line

A control method and cold forming technology, applied in the control of cold forming production line, in the field of cold forming production line, can solve the problems of poor product uniformity, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

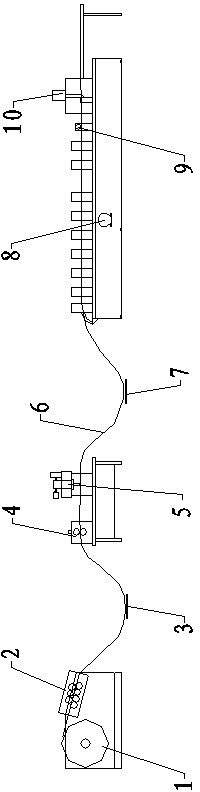

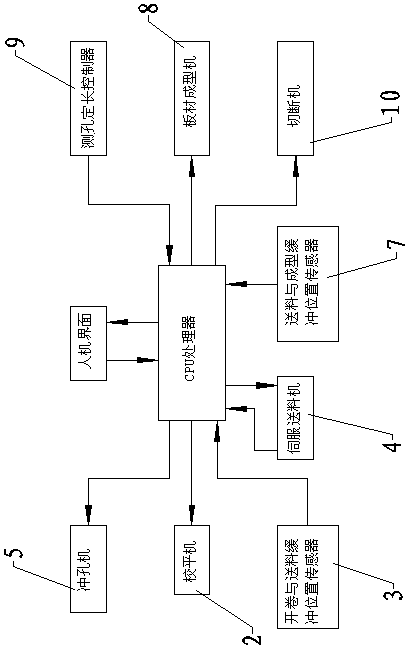

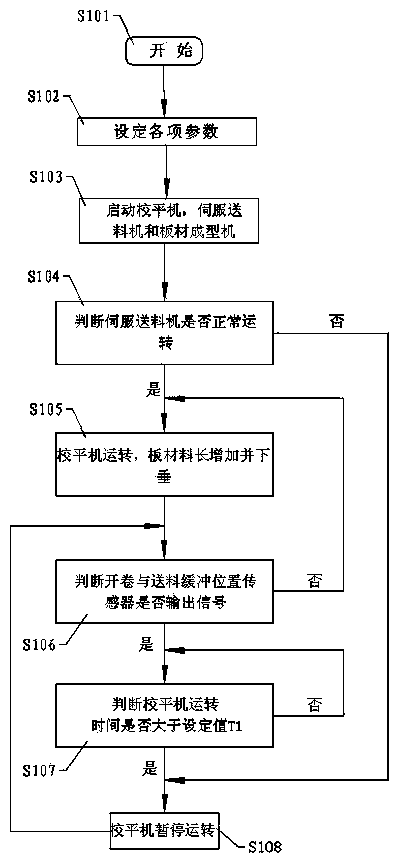

[0046] Examples such as figure 1 , figure 2 As shown, a device for a cold roll forming production line includes a discharge rack 1, a leveling machine 2, a servo feeder 4, a punching machine 5, a plate forming machine 8, a hole measuring and length fixing controller 9 and a cutting machine arranged in sequence. Machine 10, an uncoiling and feeding buffer zone is set between the leveling machine 2 and the servo feeder 4, the plate 6 in the uncoiling and feeding buffer zone is in a drooping state, and the uncoiling and feeding buffer position sensor is provided at the bottom of the uncoiling and feeding buffer zone 3. The setting position of the uncoiling and feeding buffer position sensor 3 is lower than the height of the plate 6 in the leveling machine 2 and the servo feeder 4. There is a feeding and forming buffer between the punching machine 5 and the plate forming machine 8. The feeding and forming buffer The sheet 6 in the forming buffer zone is in a drooping state, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com