Filament exchange jig and filament exchange structure

A replacer and filament technology, applied in the direction of discharge lamps, gas discharge lamp parts, discharge tubes, etc., can solve the problems of heavy weight, increase the burden on replacement operators, etc., and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

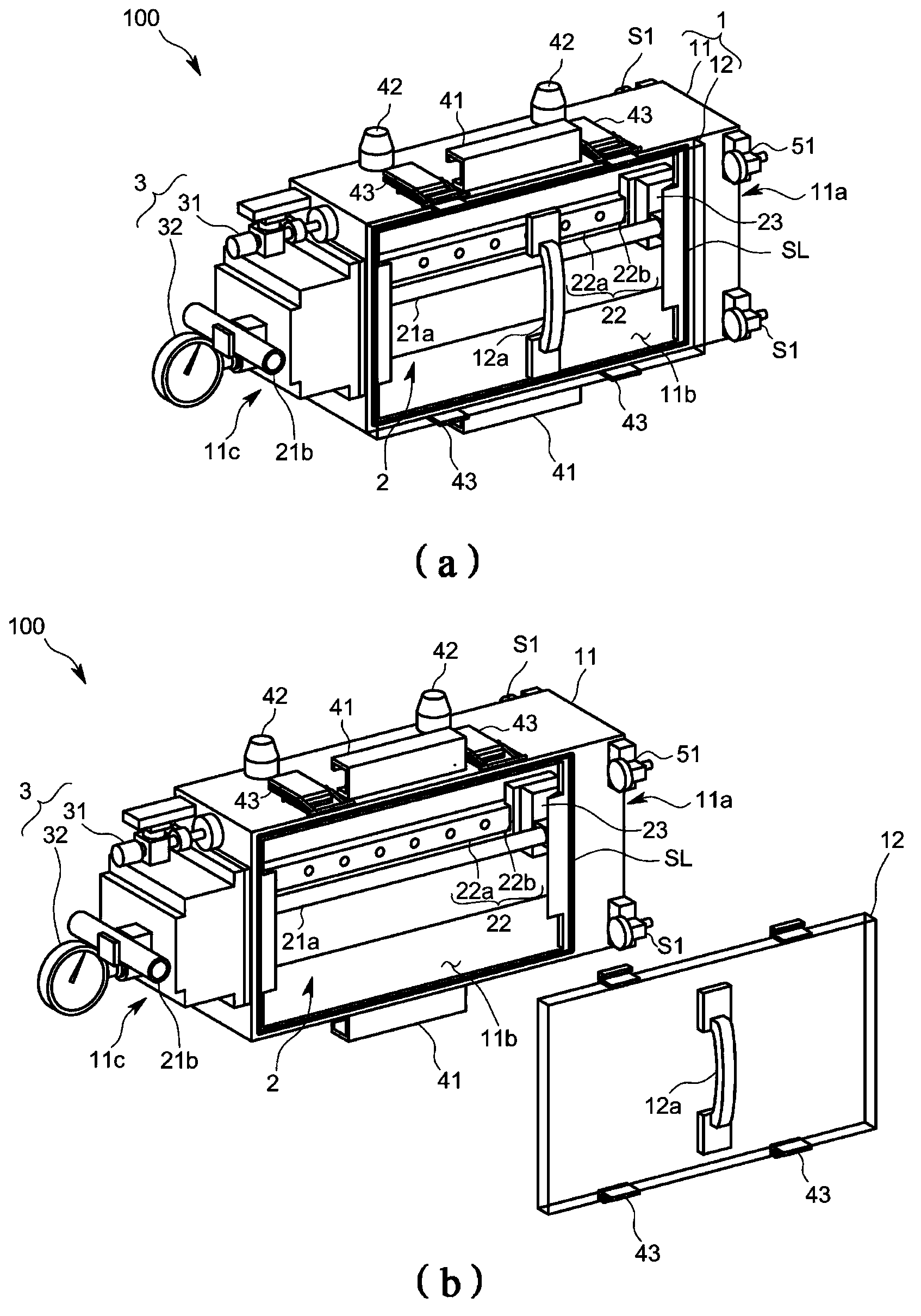

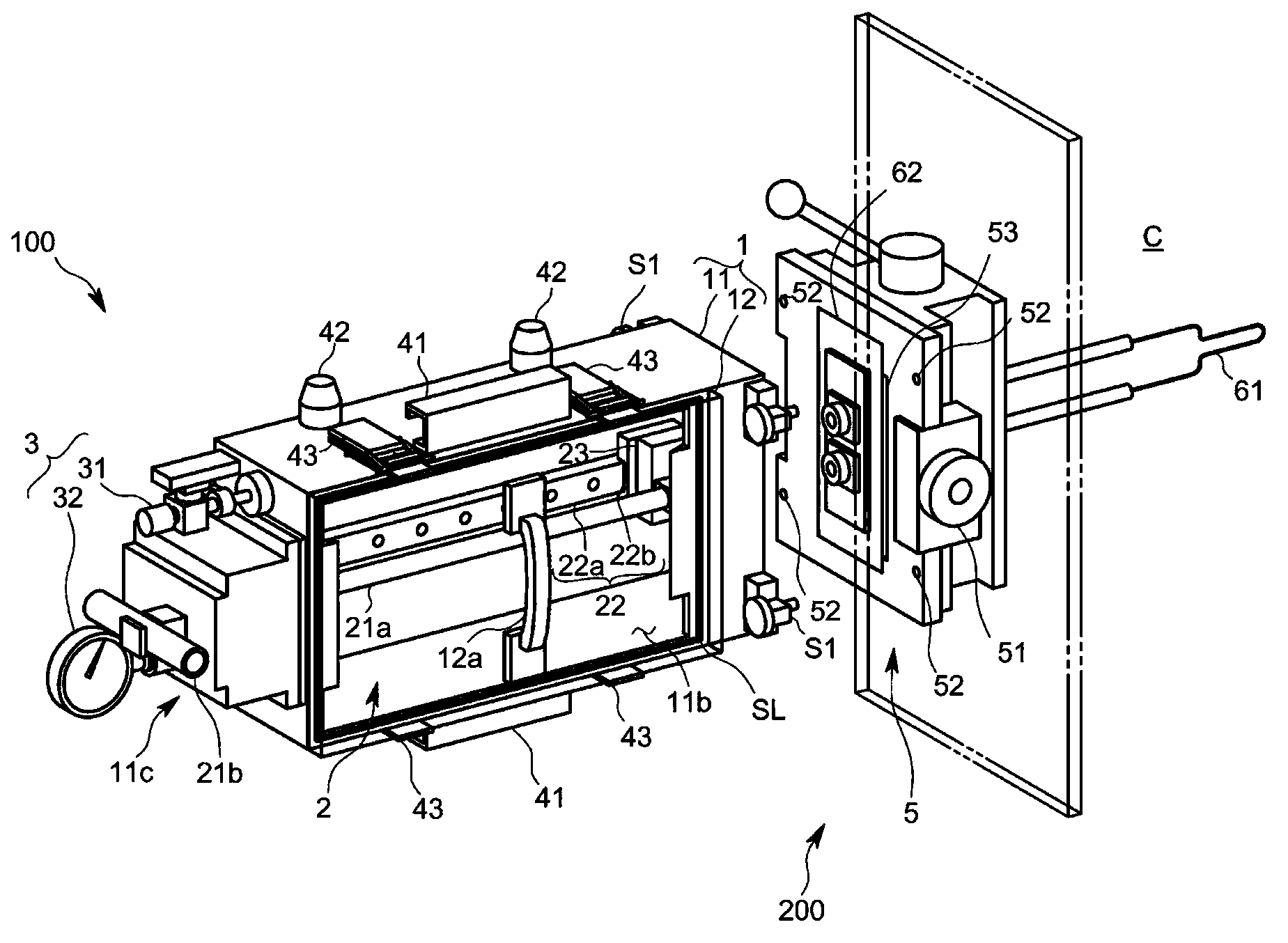

[0060] A filament changer 100 and a filament replacement structure 200 according to one embodiment of the present invention will be described with reference to the drawings.

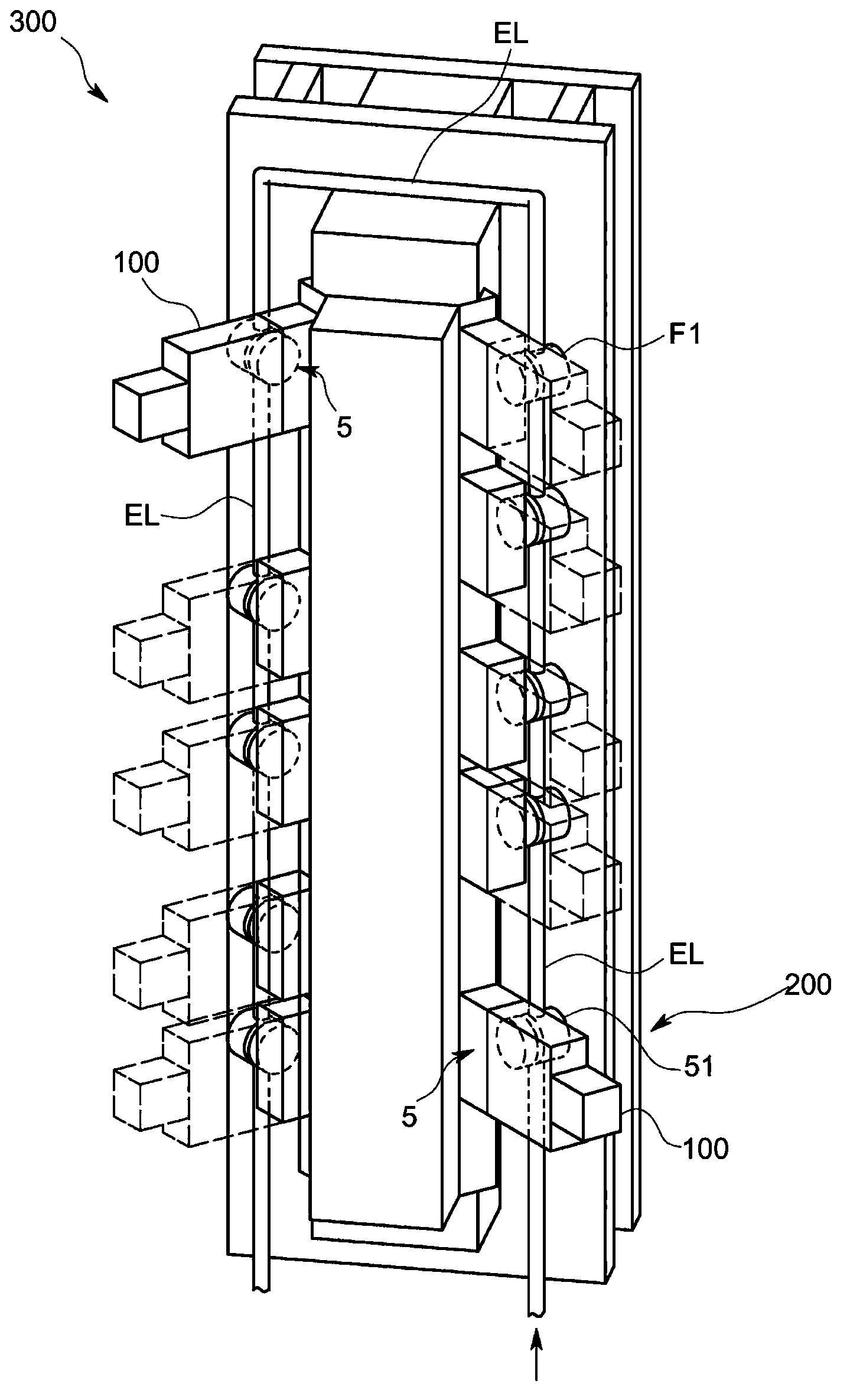

[0061] The filament replacer 100 of this embodiment is used to replace the filament 61 of an ion source 300 that generates an ion beam for implanting ions into a liquid crystal glass substrate or a semiconductor substrate, for example, in manufacturing a liquid crystal display or a semiconductor device. In addition, the filament changer 100 can also be used to replace the filament 61 of the electron source that generates electron beams. Next, replacement of the filament 61 arranged in the plasma generation chamber of the vacuum chamber C serving as the ion source 300 will be described as an example.

[0062] For example figure 1 As shown, the ion source 300 is a multi-filament ion source in which a plurality of filaments 61 are arranged in the vertical direction. More specifically, the flanged current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com