Luminous unit and luminous module thereof

A light-emitting unit and light-emitting module technology, which is applied in the direction of electrical components, lighting and heating equipment, circuits, etc., can solve the problems of high cost, achieve the effects of improving heat conduction efficiency, simplifying assembly, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] A light emitting unit and a light emitting module thereof according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

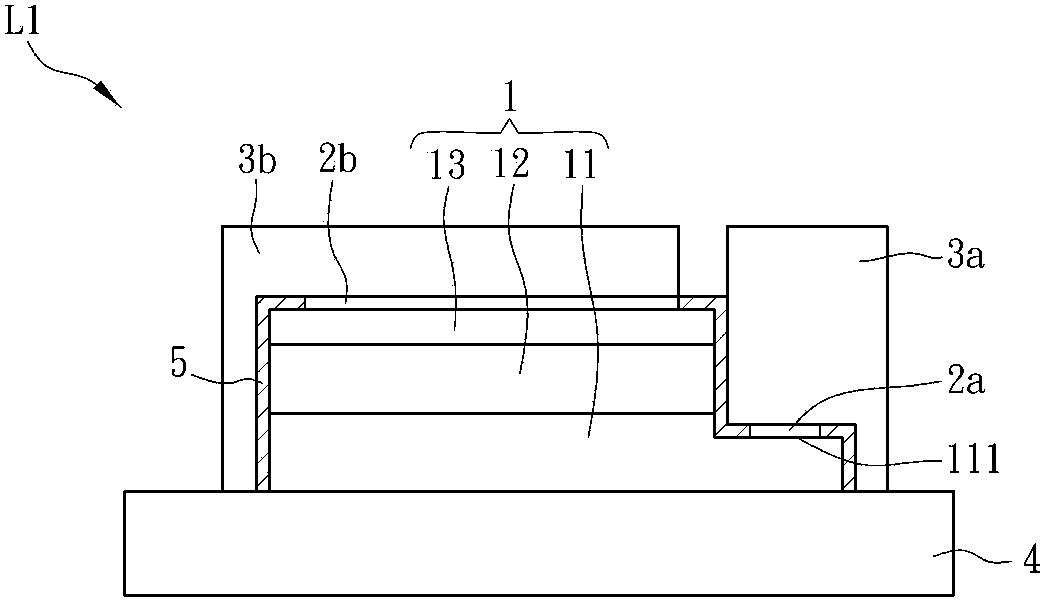

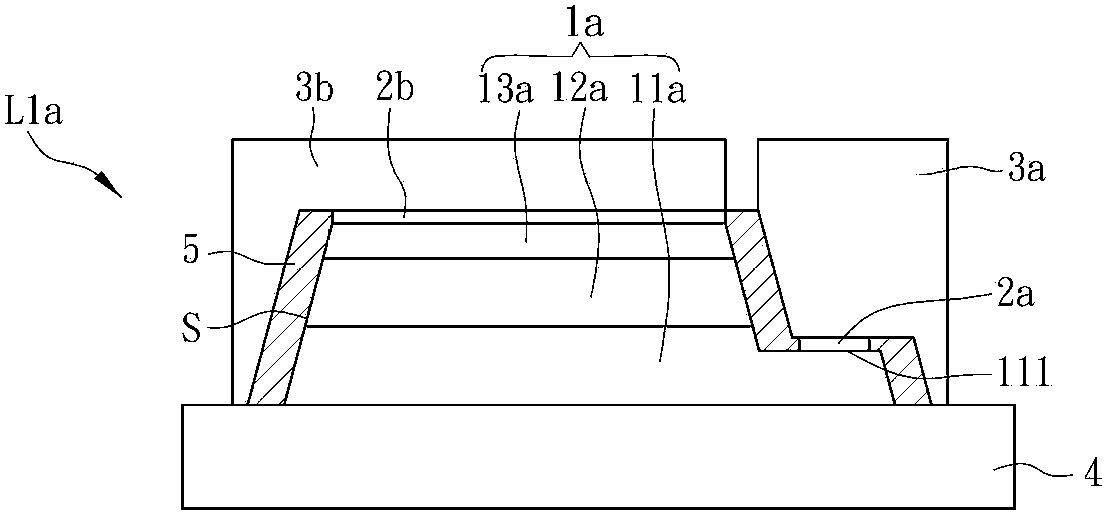

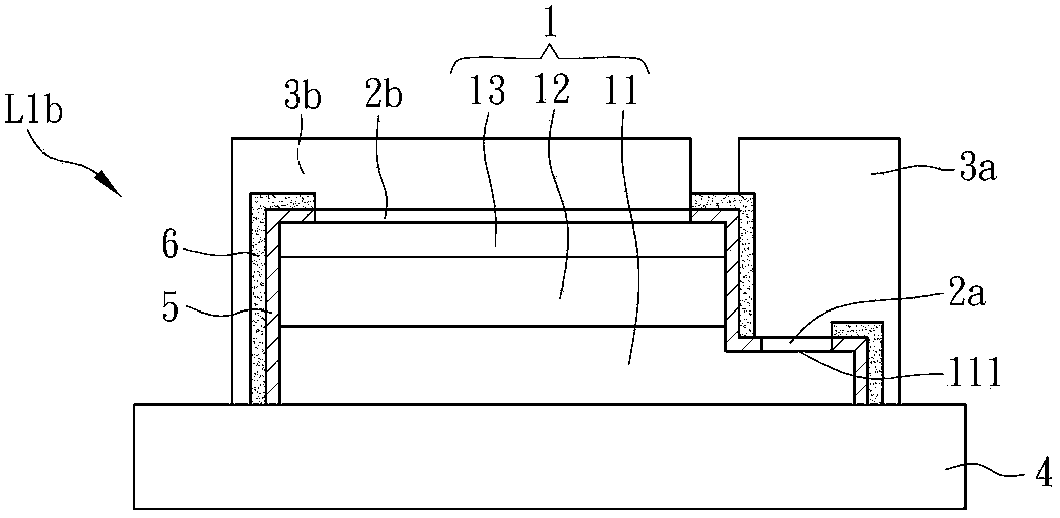

[0069] figure 1 It is a schematic cross-sectional view of a light emitting unit L1 according to the first preferred embodiment of the present invention. Such as figure 1 As shown, the light emitting unit L1 includes an epitaxial stack 1, at least one first electrode 2a, at least one second electrode 2b, a first bonding pad 3a and a second bonding pad 3b. Here, the light emitting unit L1 uses a light emitting diode as its light source.

[0070] The epitaxial stack 1 sequentially includes a first semiconductor layer 11, a light emitting layer 12 and a second semiconductor layer 13, by etching the light emitting layer 12 and the second semiconductor layer 13 to expose part of the first semiconductor layer 11, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com