Ship-borne power source

A technology of power supply and auxiliary power supply, which is applied in the direction of conversion equipment for intermediate conversion to direct current, which can solve the problems that ordinary power supplies are difficult to meet, achieve the effects of small voltage and current stress, reduce switching loss, and increase output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

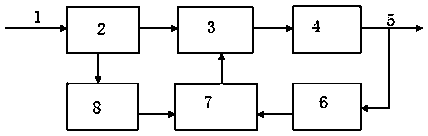

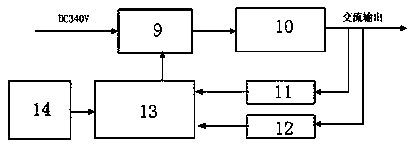

[0013] Such as figure 1 As shown, the purpose of the present invention is achieved in this way, a shipboard power supply is characterized in that it includes at least: an input filter 2, a DC / DC conversion circuit 3, a rectification filter circuit 4, a detection circuit 6, and a PWM control circuit 7 1. The front-stage DC / DC unit and DC / AC unit formed by the auxiliary power supply 8, the AC input 1 is divided into two channels after being filtered by the input 2, and one channel is input to the DC / DC conversion circuit 3 and the rectification filter circuit 4, and then output to the load; The other one is input to the input terminal of the auxiliary power supply 8, and the auxiliary power supply 8 generates the working voltage required by the PWM control circuit 7, and supplies the voltage to the PWM control circuit 7, and the DC output 5 of the rectification and filtering circuit 4 is electrically connected to the voltage and current detection circuit 6 , the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com