Grease composition

A technology for lubricating grease composition and equipment, which is applied in the direction of lubricating composition, mechanical equipment, thickener, etc., can solve the problems of not preventing hydrogen or hydrogen embrittlement, and achieves excellent resistance to hydrogen embrittlement peeling and long lubrication life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

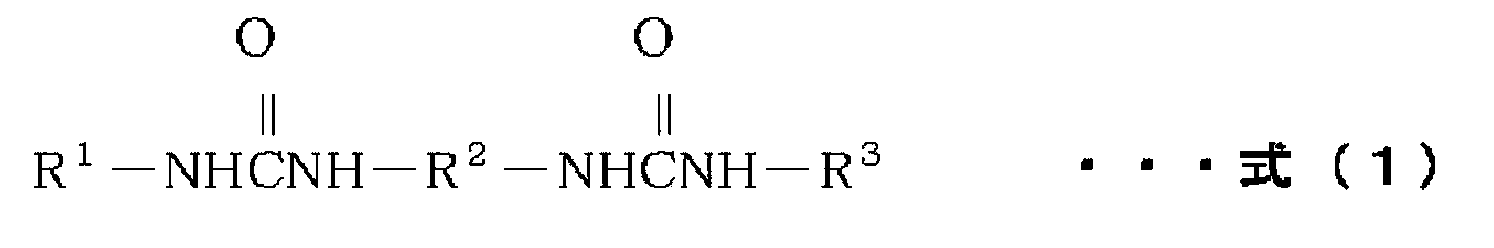

Method used

Image

Examples

Embodiment

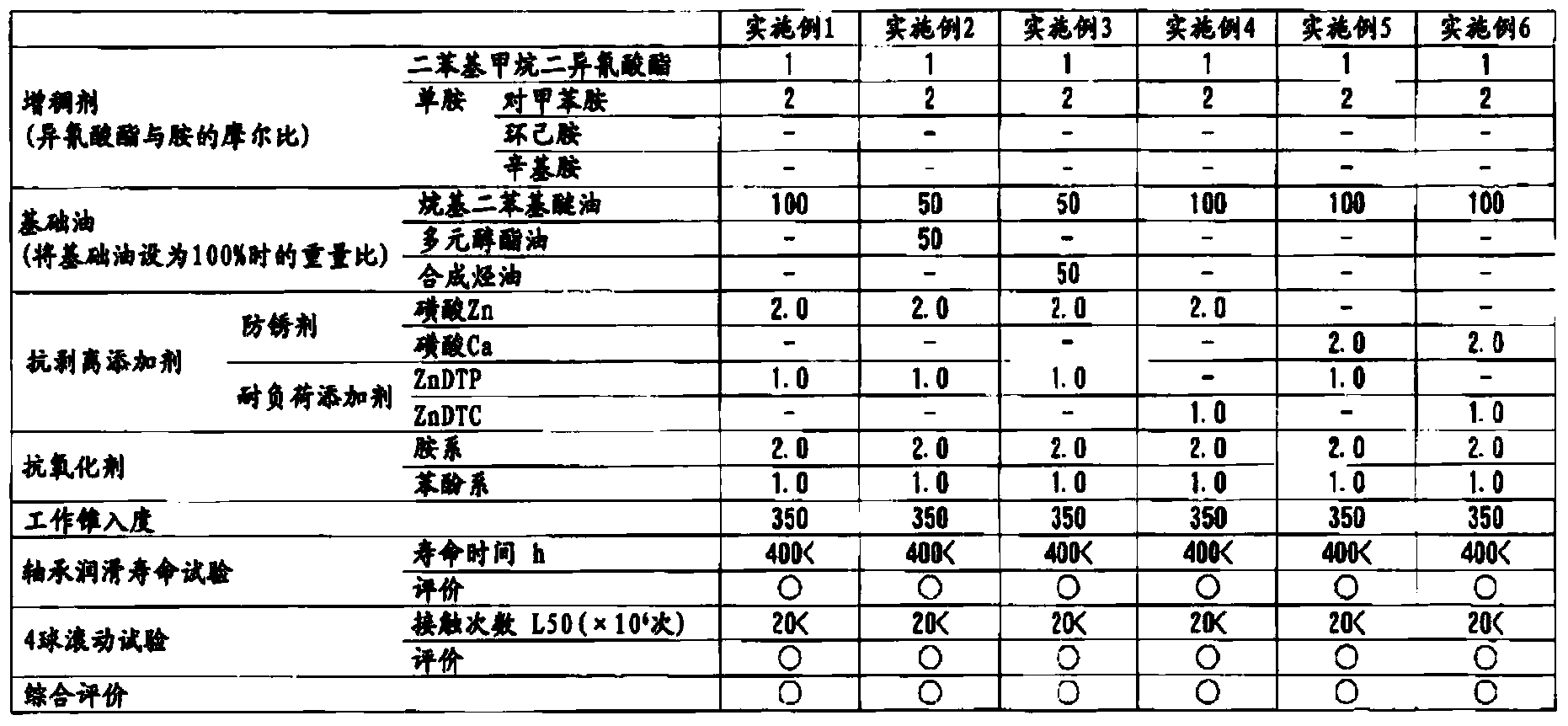

[0075] Adjustment of Test Grease

[0076] In the following base oil, 1 mol of diphenylmethane diisocyanate and monoamine (cyclohexylamine, octylamine, p-toluidine) were reacted, and after heating and cooling, the base oil and fat were obtained. The following additives and base oil were added to the base grease, and after grinding with three rollers, the working penetration was 350 to obtain the grease compositions of Examples 1-6 and Comparative Examples 1-8.

[0077] base oil

[0078] ○Alkyl diphenyl ether oil

[0079] · C12~C14 alkyl diphenyl ether oil: kinematic viscosity at 40°C = 97mm 2 / s

[0080] ○Polyol ester oil

[0081] · Dipentaerythritol ester oil: kinematic viscosity at 40°C = 76.9mm 2 / s

[0082] ○Synthetic hydrocarbon oil

[0083] ・Polyα-olefin oil: kinematic viscosity at 40°C = 68.0mm 2 / s

[0084] Anti-stripping additives

[0085] Rust inhibitor

[0086] ○Sulfonic acid Zn

[0087] ·Zn salt of dinonylnaphthalenesulfonic acid

[0088] ○Sulfonic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com