Brine dotting mechanism used for bean curd machine and full-automatic bean curd machine

A tofu machine, fully automatic technology, used in applications, cheese substitutes, dairy products, etc., can solve the problem that the coagulant cannot flow out smoothly when the brine is placed, it is difficult to control the timing and amount of pulp, and the quality of tofu cannot be maintained, etc. The problem is to prevent the precipitation of the halogen point agent, avoid secondary pollution, and achieve the effect of uniform taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

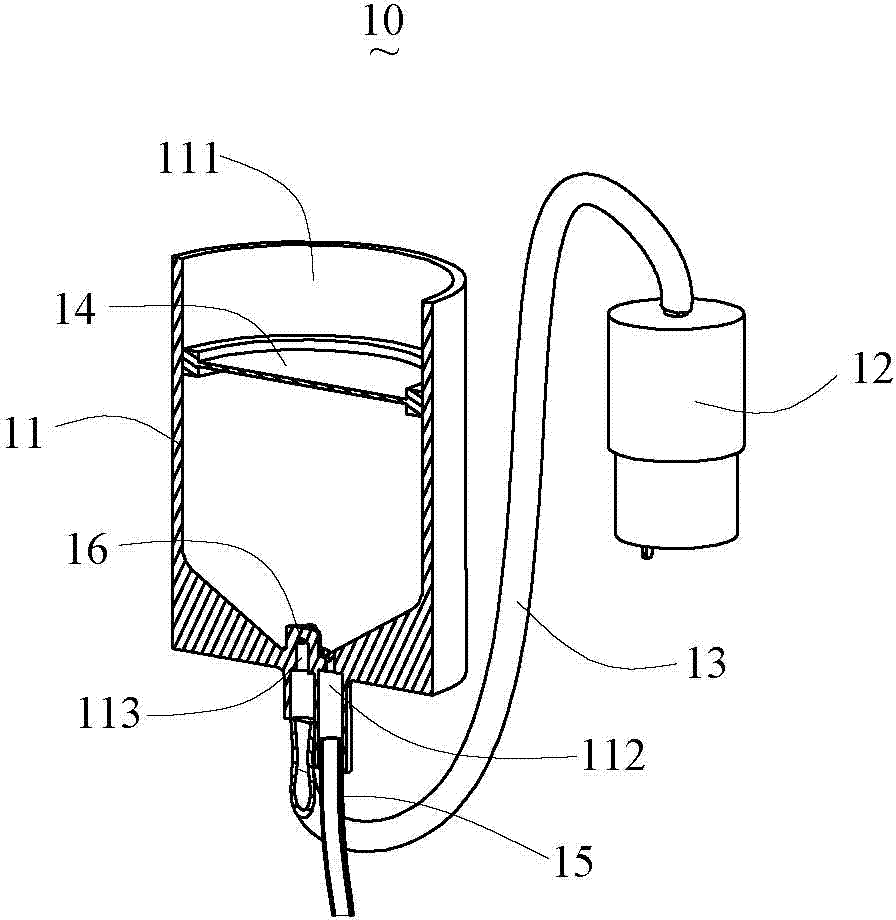

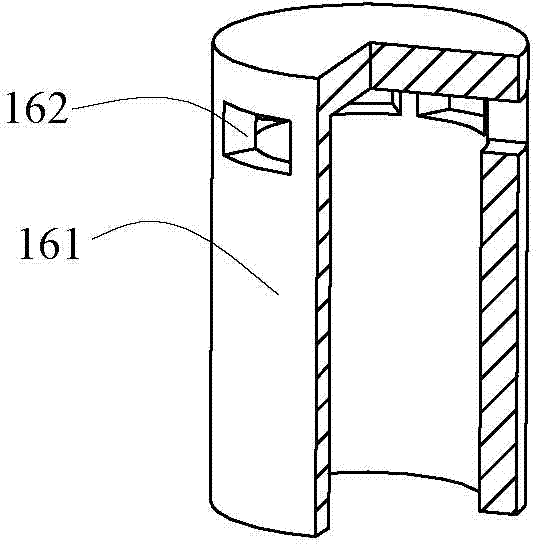

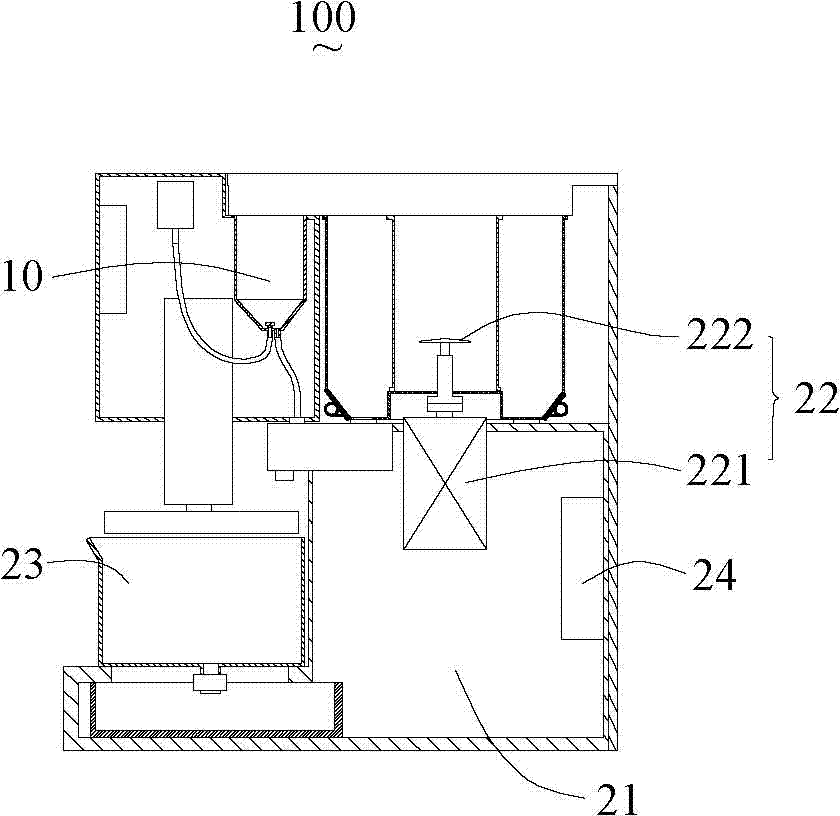

[0031] see figure 1 Shown is the first preferred embodiment of the stew pointing mechanism for the tofu machine of the present invention. The stew pointing mechanism 10 for the tofu machine includes a stew pointing box 11 with an opening 111 for holding a bittern pointing agent, an air pump 12 , air intake pipe 13 and filter element 14, this halogen point box 11 is provided with liquid outlet 112, and this halogen point mechanism 10 is provided with the valve of opening and closing liquid outlet 112, and this air pump 12 is blown to point halogen box 11 through intake pipe 13 Gas stirs the halogen pointing agent in the halogen pointing box 11, for example: the filter element 14 divides the halogen pointing box 11 into upper and lower chambers.

[0032] In this embodiment, the ratio of the blowing pressure of the air pump 12 to the liquid level pressure to the halogen spotting box 11 is greater than or equal to 1.5, for example, 2, 3, 4, 5, 6, etc., so that the power of the gas...

Embodiment approach 2

[0041] see Figure 4 Shown is the second preferred embodiment of the stew pointing mechanism used by the tofu machine of the present invention, the difference between the stew point mechanism 30 used by the tofu machine and the point stew mechanism 10 used by the tofu machine is: the side wall of the stew point box 31 An air inlet 311 is provided, and the air inlet 311 is arranged in the tangential direction of the side wall.

[0042] In this embodiment, the air inlet 311 is below the liquid level of the halogen spotting agent in the halogen spotting box 31 , which can achieve better stirring effect.

[0043] In this way, the gas is blocked by the side wall of the halogen spotting box 31 to form a vortex, which makes the stirring effect better. In addition, the liquid outlet 312 is set at the center of the bottom wall and the inner surface of the bottom wall is tapered, so that the halogen pointing agent flows out more thoroughly, reducing the point Residual amount in halogen...

Embodiment approach 3

[0045] see Figure 5 Shown is the second preferred embodiment of the stewed mechanism for tofu machine of the present invention, the difference between the stewed mechanism 40 used for the tofu machine and the stewed mechanism 10 used by the tofu machine is: the center of the filter element 41 is provided with a through hole hole 411, the air inlet pipe 13 passes through the through hole 411 and extends into the lower chamber of the halogen point box 42, the end of the air inlet pipe 13 is provided with a gas diffuser 43, and the gas diffuser 43 includes 6 air holes 431, the The gas diffuser 43 is integrally formed with the intake pipe 13 .

[0046] In this way, the intake pipe 13 can be easily disassembled and cleaned, which is more convenient for users to use.

[0047] It can be understood that the gas diffuser can also be detachably installed on the intake pipe 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com