Process for comprehensively recovering ferrum, molybdenum and sericite from gold concentrator tailings

A technology for sericite and iron recovery, applied in the field of comprehensive recovery of iron from molybdenum, sericite and tailings, can solve problems such as waste, and achieve the effect of stable operation and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

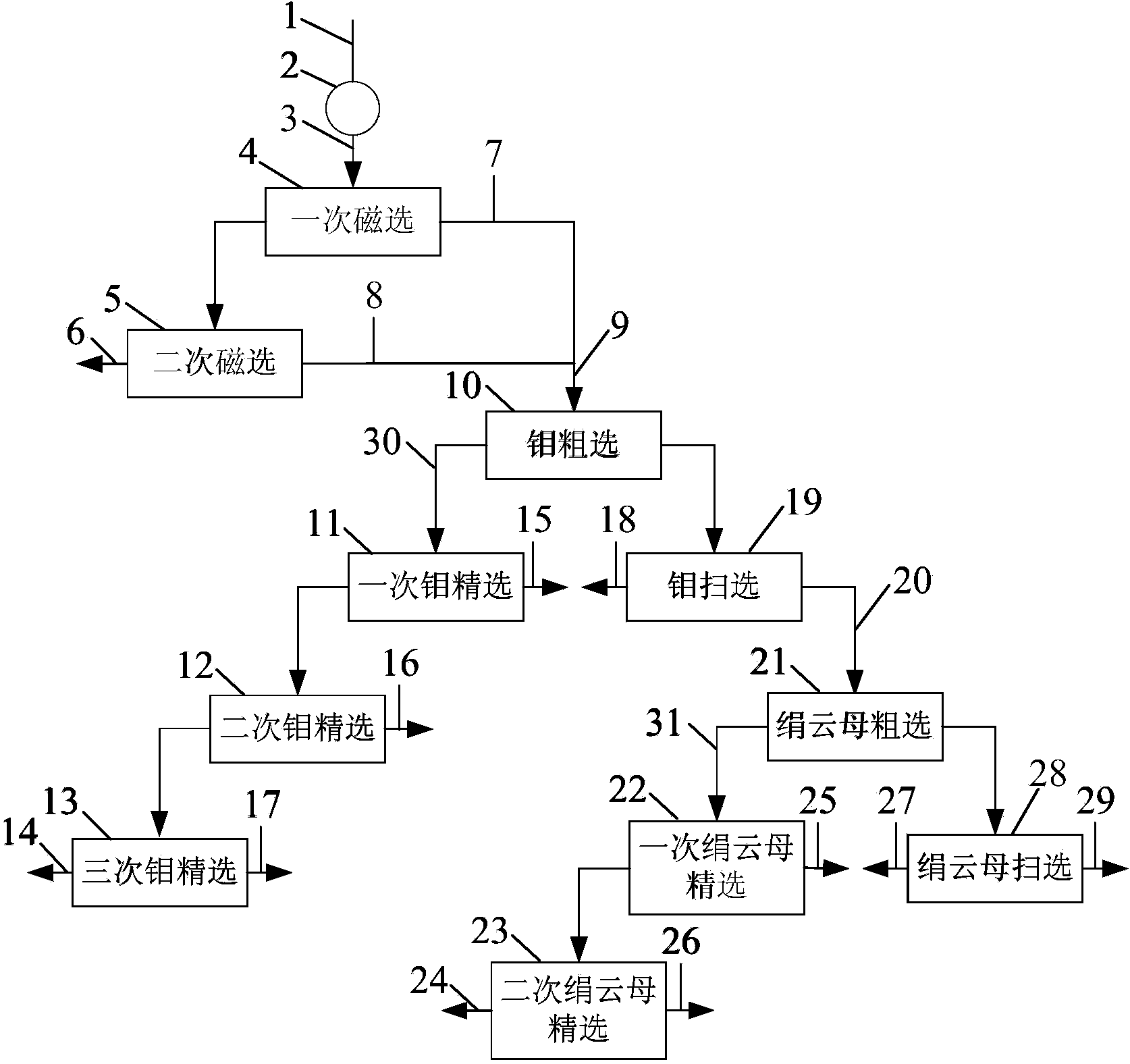

Method used

Image

Examples

Embodiment 1

[0021] Step A: Grinding, the gold beneficiation tailings (1) enter the grinding (2), and the ore discharge product (3) of the grinding (2) is obtained, and the fineness of the ore discharge product (3) is -0.074mm, accounting for 85.15% ;

[0022] Step B: ferromagnetic separation operation, the ore discharge product (3) undergoes a magnetic separation operation composed of a magnetic separation (4) and a second magnetic separation (5). The magnetic field strength of the first magnetic separation is 151.1kA / m, and the second magnetic separation The selected magnetic field strength is 79.5kA / m, and the magnetic separation concentrate (6) is obtained;

[0023] Step C: Molybdenum flotation operation, the primary magnetic separation tailings slurry (7) and the secondary magnetic separation tailings slurry (8) are combined to form the molybdenum beneficiation feed (9), and the molybdenum beneficiation feed (9) is sequentially added with dispersion inhibitors (water glass: 300g / t), ...

Embodiment 2

[0031] Step A: Grinding, the gold beneficiation tailings (1) enter the grinding (2), and the ore discharge product (3) of the grinding (2) is obtained, and the fineness of the ore discharge product (3) is -0.074mm, accounting for 87.31% ;

[0032]Step B: ferromagnetic separation operation, the ore discharge product (3) undergoes a magnetic separation operation composed of a magnetic separation (4) and a second magnetic separation (5). The magnetic field strength of the first magnetic separation is 151.1kA / m, and the second magnetic separation The selected magnetic field strength is 79.5kA / m, and the magnetic separation concentrate (6) is obtained;

[0033] Step C: Molybdenum flotation operation, the primary magnetic separation tailings slurry (7) and the secondary magnetic separation tailings slurry (8) are combined to form the molybdenum beneficiation feed (9), and the molybdenum beneficiation feed (9) is sequentially added with dispersion inhibitors (water glass: 400g / t), c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com