Degassing process for low-gas-content centrifugal composite roll

A technology of centrifugal compounding and rolls, which is applied in the field of roll production, can solve problems such as degassing of centrifugal compounding rolls, and achieve the effects of reducing gas content, simple equipment, and convenient and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

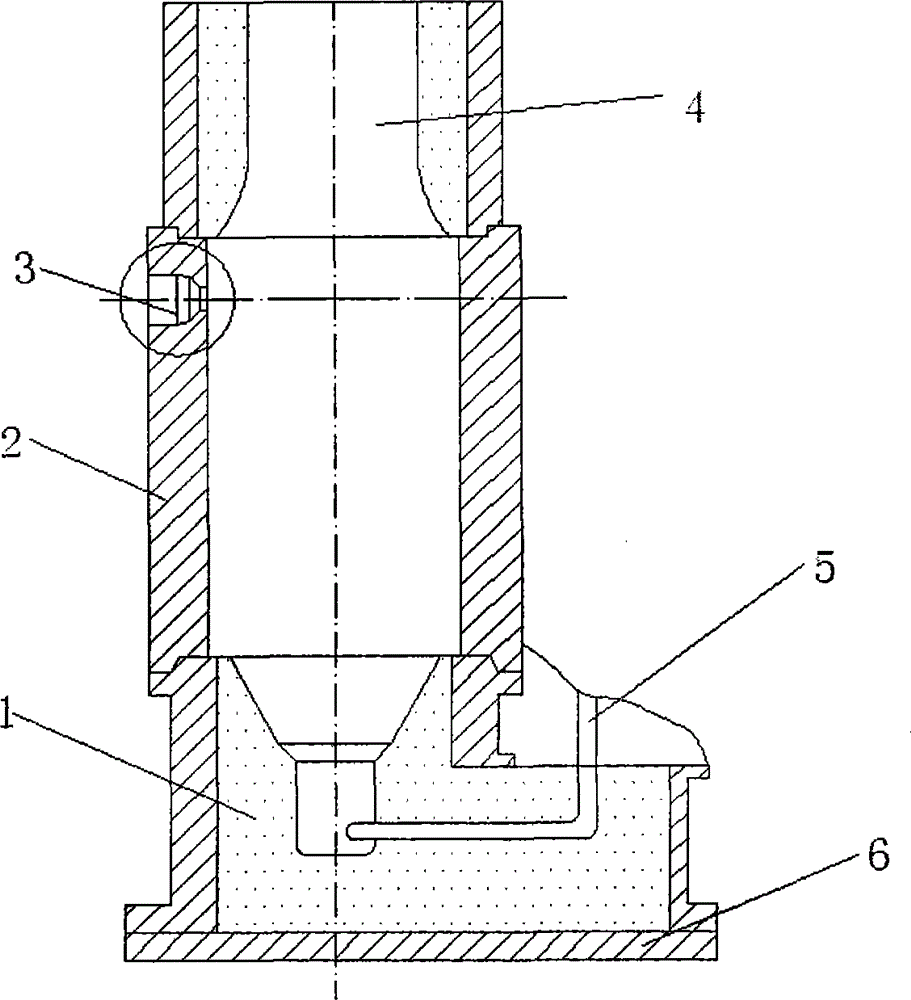

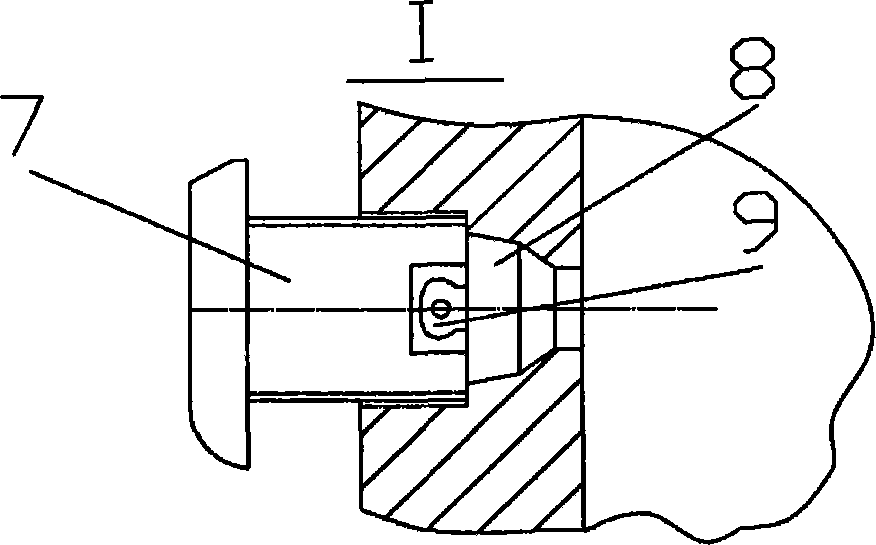

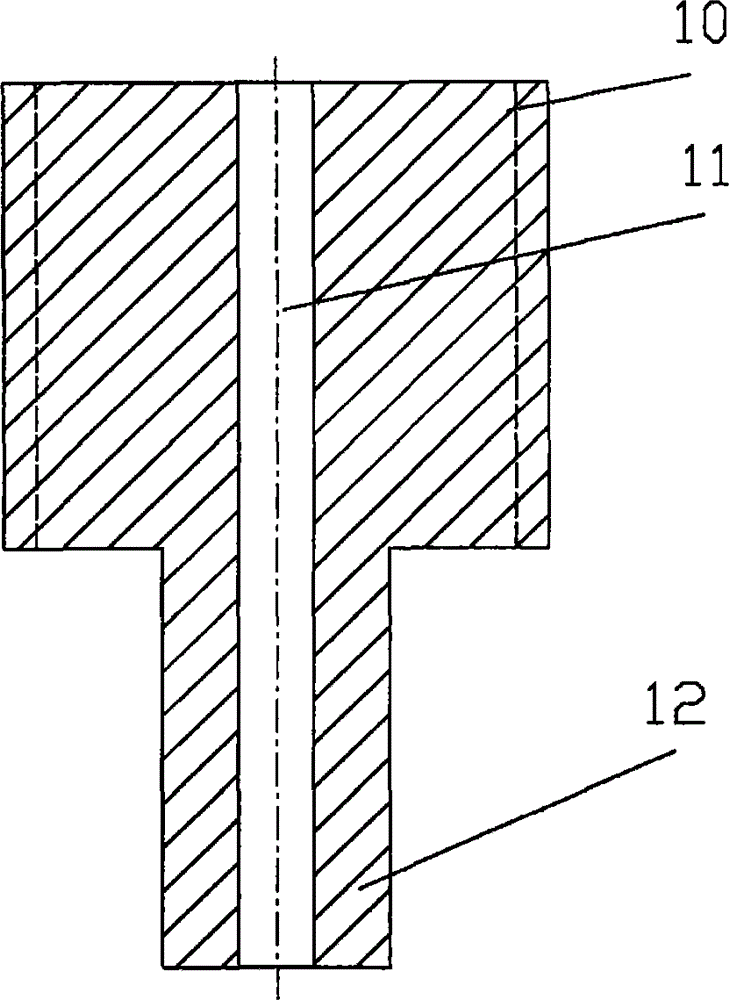

[0026] figure 1 , 2 It is a schematic diagram of the structure of the centrifugal composite roll, the metal mold of the roll body and the vacuum hole in the degassing process of the low-gas centrifugal composite roll. The present invention will be further described below in conjunction with specific embodiment, and the degassing process of this low-gas centrifugal composite roll, its concrete steps are as follows:

[0027] step 1:

[0028] Process the tapered through hole 3 of the plug block 8 in the metal mold hanger 7 mounting holes on both sides of the roller body metal mold 2, and the tapered through hole 3 is directly connected to the metal mold inner cavity. The metal type hanging handles 7 are arranged on both sides of the metal type of the roller body, and each side is provided with 1-4 hanging handles. In this embodiment, according to the diameter and length of the centrifugal composite roll, the number of tapered through-holes for processing and installing plugs i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com