Machining method for oblique hole in cylinder liner hole of cylinder block of diesel engine

A processing method and cylinder liner hole technology, applied in the field of mechanical processing, can solve problems such as long working hours, poor operating conditions, and difficulty reaching the cylinder liner hole 1, and achieve the effects of avoiding potential safety hazards, improving product quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following describes the present invention in further detail with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited by this.

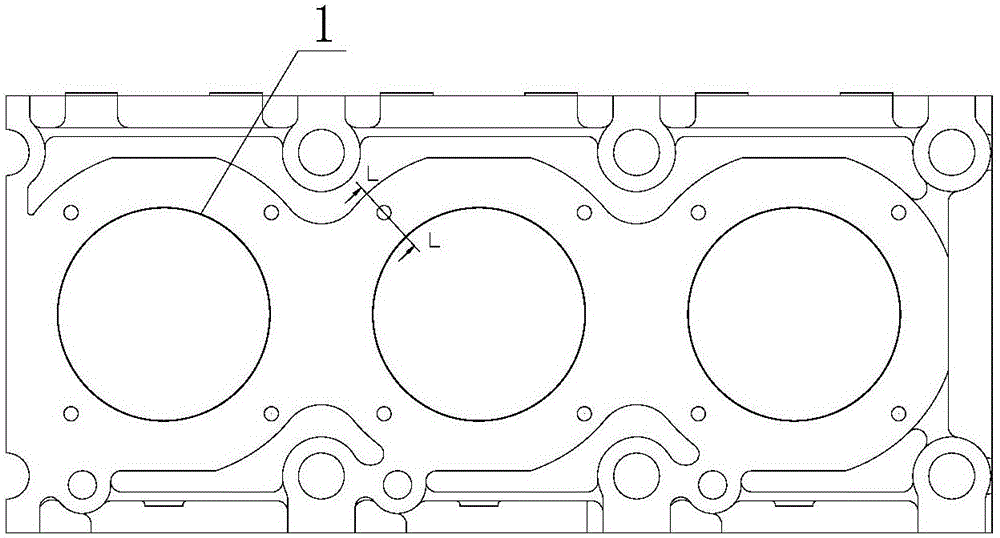

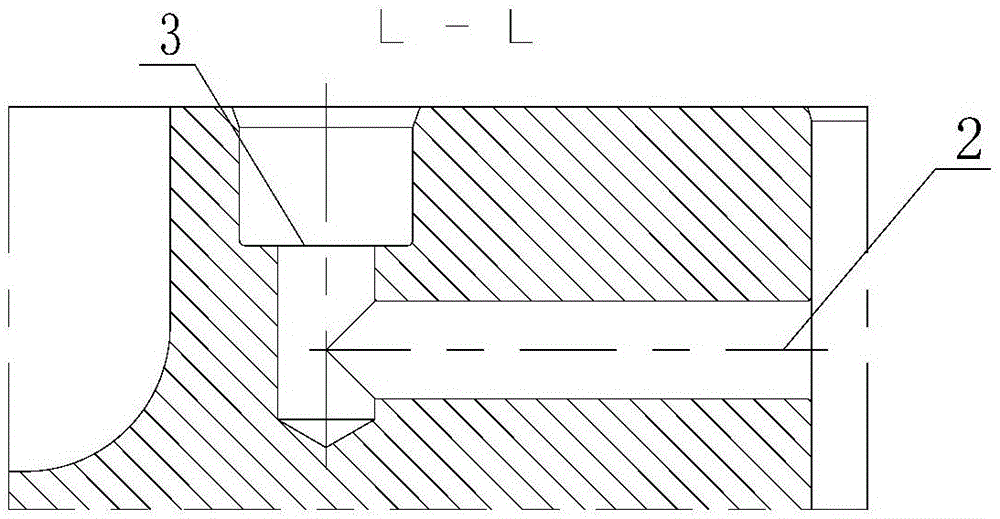

[0029] The processing method of the present invention is used for processing oblique holes in cylinder bores of diesel engine cylinder blocks. See figure 1 with figure 2 A schematic structural diagram of the cylinder block of a diesel engine. The cylinder block is provided with a number of cylinder liner holes 1 and four vertical holes 3 evenly arranged around the cylinder liner hole 1, and each cylinder liner hole 1 is provided with four inclined holes 2 , Each oblique hole 2 penetrates a vertical hole 3 and forms 90°; the four oblique holes 2 are evenly distributed and form 45°, 135°, 225° and 315° with the horizontal plane respectively.

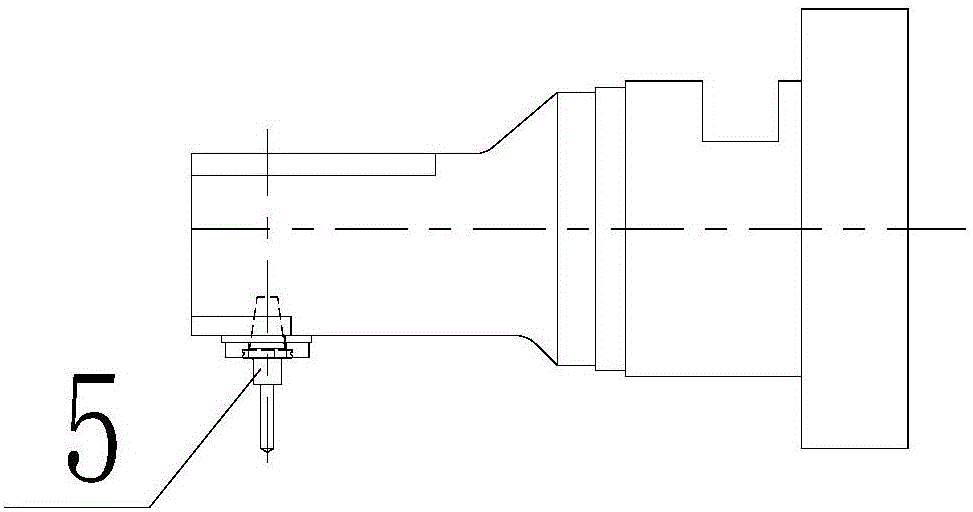

[0030] See Figure 5 The method for processing the oblique hole in the cylinder liner hole of the cylinder block of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com