Automatic saw teeth grinding device of band saw

A band saw and sawtooth technology, applied in the mechanical field, can solve the problems such as the inability to accurately adjust the angle of the grinding wheel and the complex structure of the equipment, and achieve the effect of remarkable grinding effect, improved grinding effect, and convenient replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

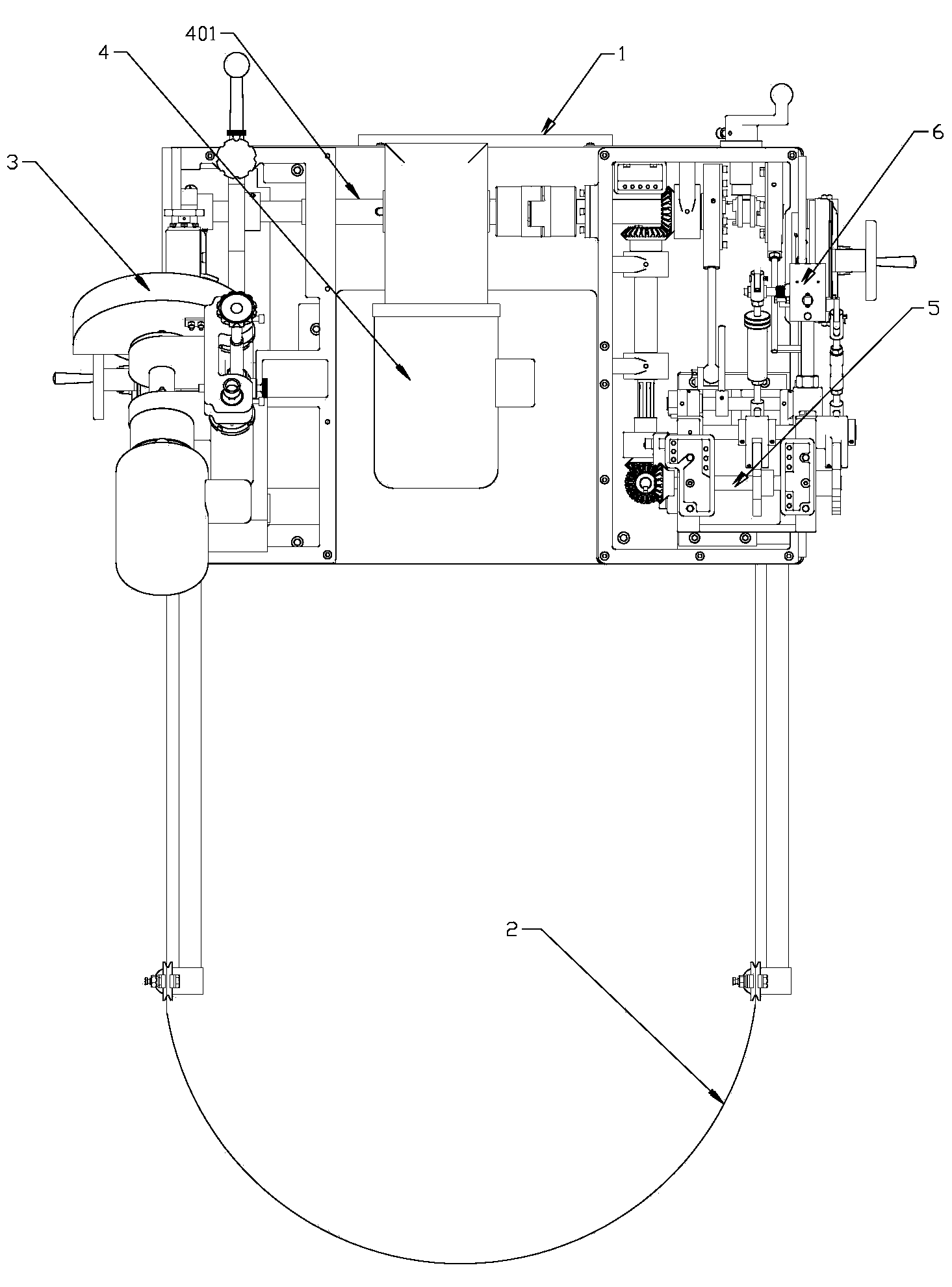

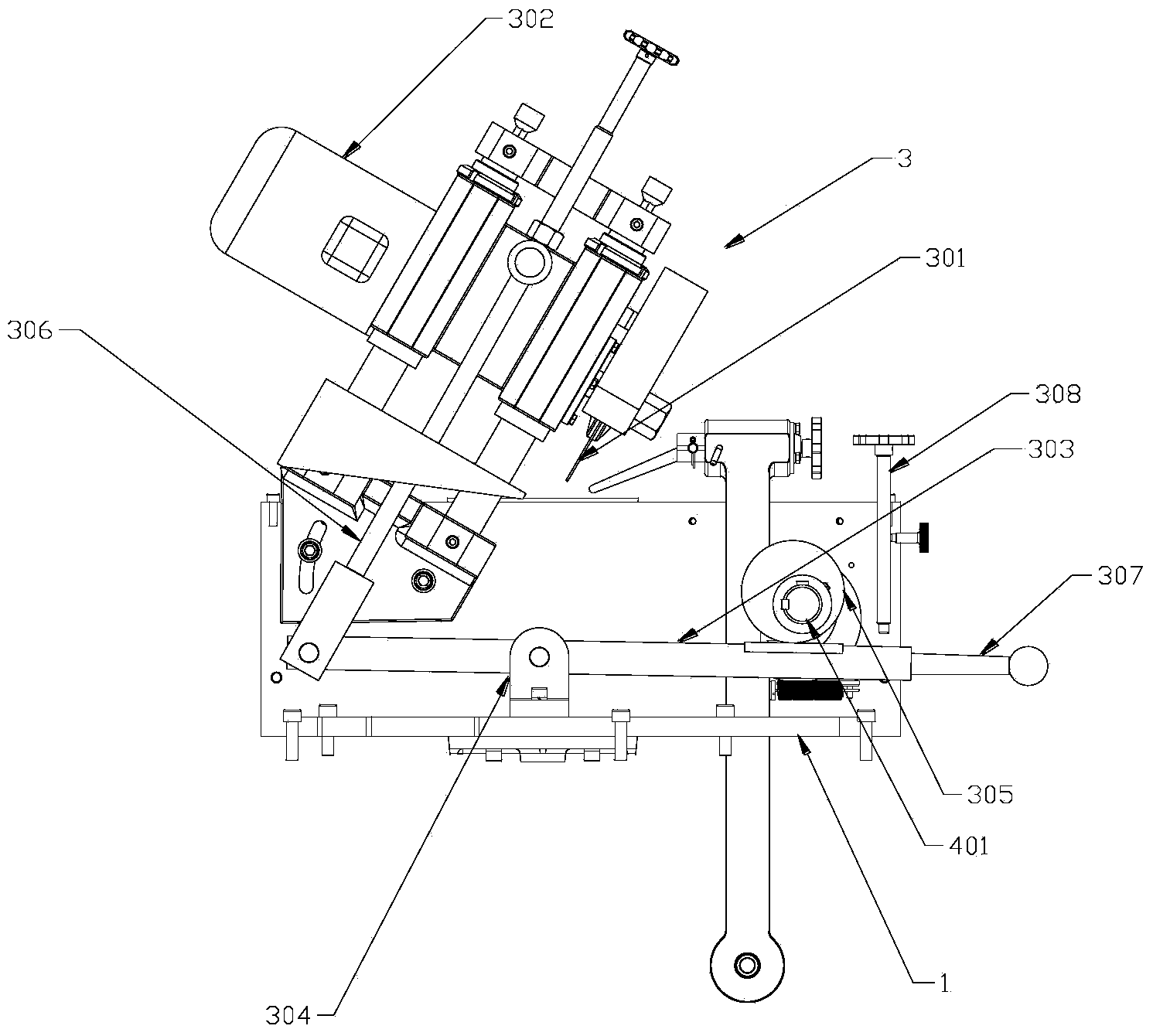

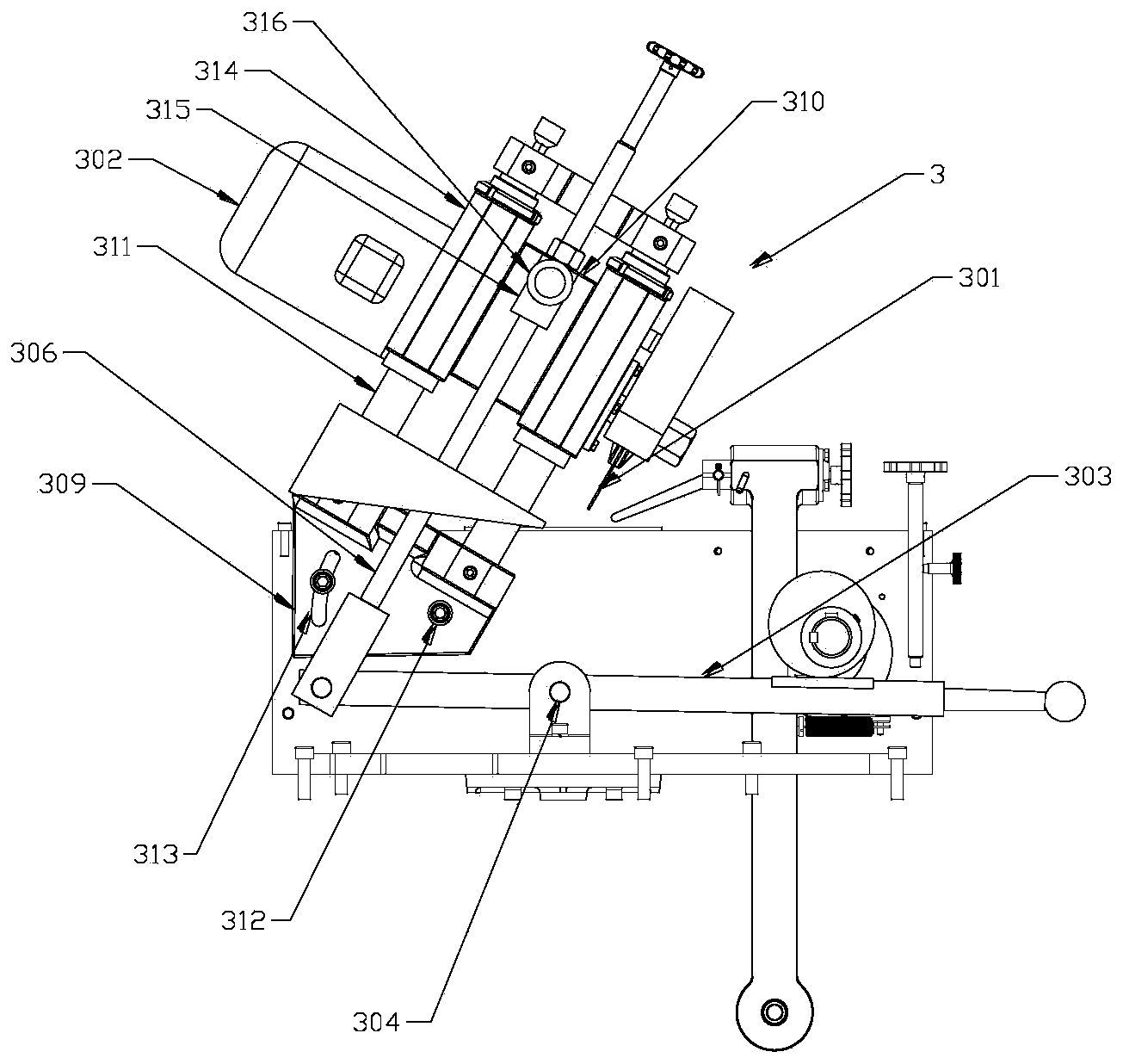

[0028] Such as figure 1 As shown, the automatic tooth grinding device for band saw teeth of the present invention includes a working frame 1 for supporting and driving the band saw 2 to rotate, a driving motor 4 that provides power for the entire device, and is installed in the working frame 1 with a grinding wheel 301 and the grinding system of the grinding wheel drive motor 302, the grinding system is connected with the power shaft 401 of the drive motor 4 through the warping rod 303, the middle part of the warping rod 303 is movably installed on the working frame through the bearing seat 304, on the power shaft 401 An eccentric wheel 305 is provided, one end of the warping rod 303 is located below the eccentric wheel 305 , and the other end of the warping rod 303 is connected to the grinding system through a push rod 306 .

[0029] The working process of the present invention is as follows: the band saw 2 to be processed is placed on the working frame 1, and the moving proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com