Method for cutting silicon ingot

A technology of silicon ingots and trays, which is applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems that affect the stability of the conversion efficiency of furnace ingots, the decrease of the overall life value of the minority carrier, and the reduction of conversion efficiency, etc., to achieve stability Primary utilization rate, increase effective rod length, and increase the effect of minority carrier life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

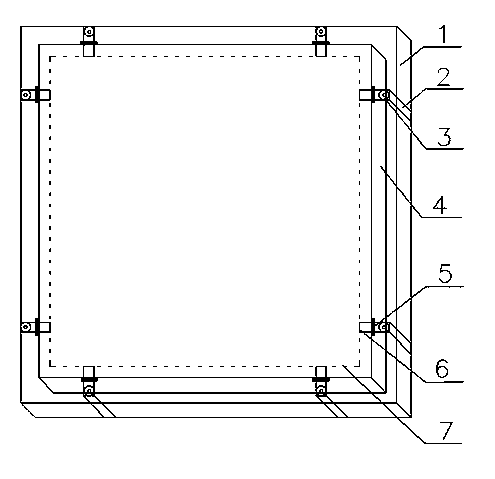

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the figure, a positioning fixture 2 is installed around the sticking tray 1, and a movable nut 3 is used on the upper side of the positioning fixture 2, which can rotate 360°. Put the silicon ingot 4 on the tray 1, turn the movable nut 3, and adjust the adjustment positioning block 5 of the positioning fixture 2, so that the distance from the positioning block 5 to the edge of the tray is consistent; with the edge 6 of the positioning fixture 2 on the silicon ingot as a reference, Mark the positioning line 7 on the silicon ingot 4; after the bonding time of the silicon ingot is more than 4 hours, when the silicon ingot is cut on the machine for alignment, the position of the cutting machine wire mesh coincides with the positioning line 7, which can ensure the cutting of the silicon ingot Alignment.

[0013] The silicon ingot cutting method of the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap