Three-layer biomass extrusion molding device and vertical biomass extrusion molding machine

A technology of extrusion molding and molding machines, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems that the extrusion molding effect of biomass materials cannot be improved, and the effect cannot be achieved, so as to improve extrusion molding Effect, improve extrusion molding efficiency, reduce energy consumption and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

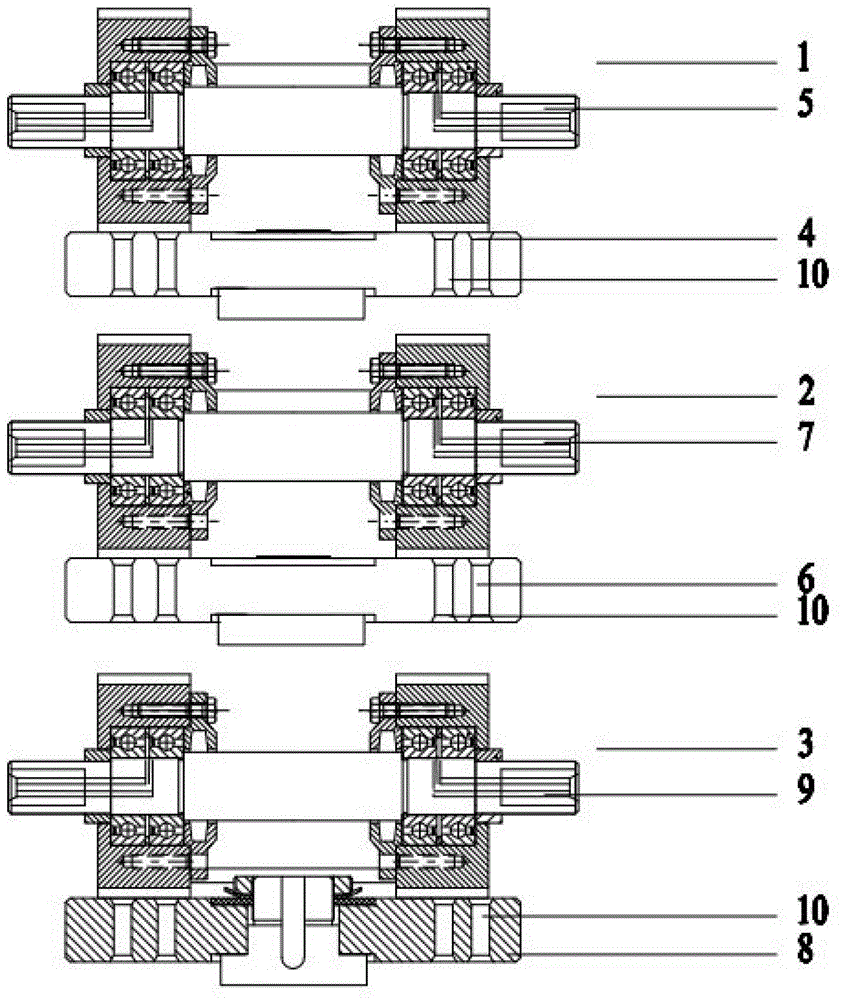

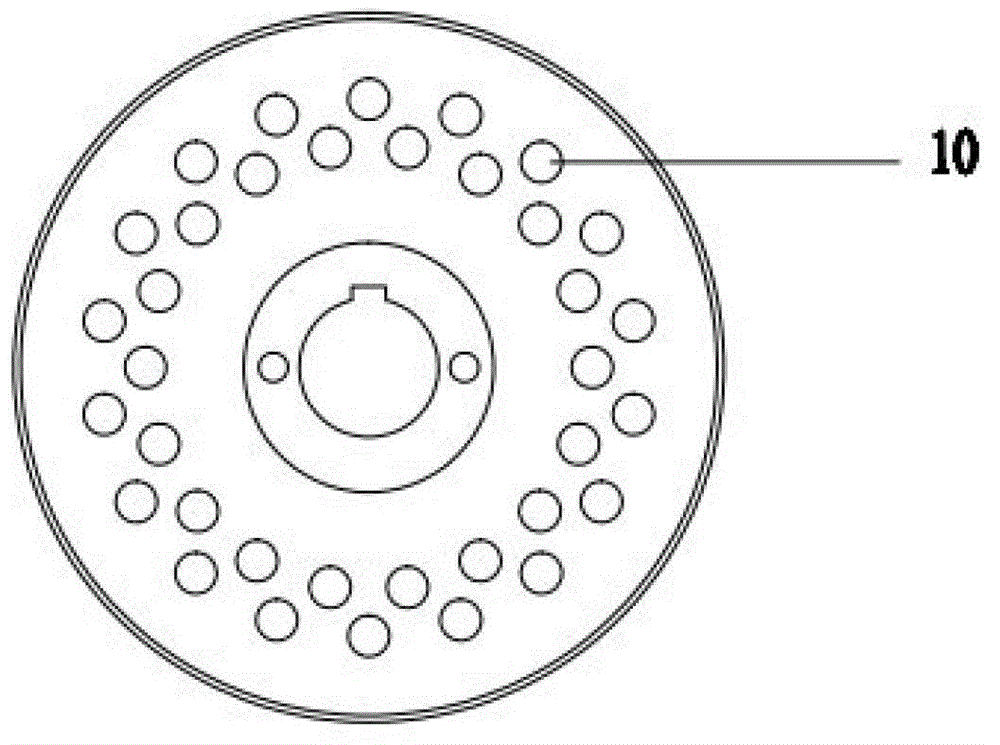

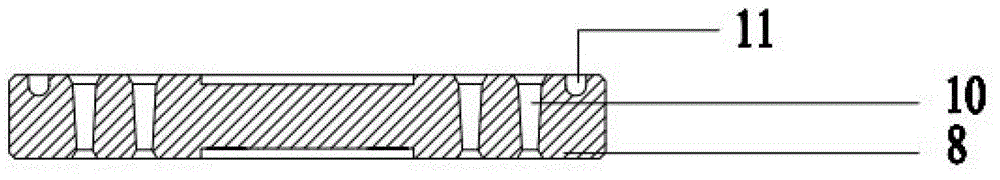

[0036] like Figure 1 to Figure 4 As shown, the present invention provides a three-layer extrusion molding device, which consists of an upper layer extrusion molding device 1, a middle layer extrusion molding device 2 and a lower layer extrusion molding device 3 arranged in sequence from top to bottom, and the upper layer extrusion molding device consists of The pressing wheel mechanism a5 and the flat die plate a4 arranged at the bottom thereof are composed. The upper extruding device is used for preliminary crushing and crushing of the material to change the flexibility of the material; the middle extruding device is composed of the pressing wheel mechanism b7 and the set The flat die plate b6 at its bottom is formed, and the middle extruding device is used for secondary extruding molding on the material to improve and enhance the extruding effect of the material; the lower extruding device is composed of the pressing wheel mechanism c9 and the It consists of a flat die disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com