Full-automatic frameless board picture cutting and assembling integrated machine

A frameless painting, fully automatic technology, applied in decorative arts, special decorative structures, pasting, etc., can solve the problems of slow process speed, poor cutting precision, slow cutting speed, etc., to achieve stable transmission and hemming speed, Facilitate error-free operation and reduce scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

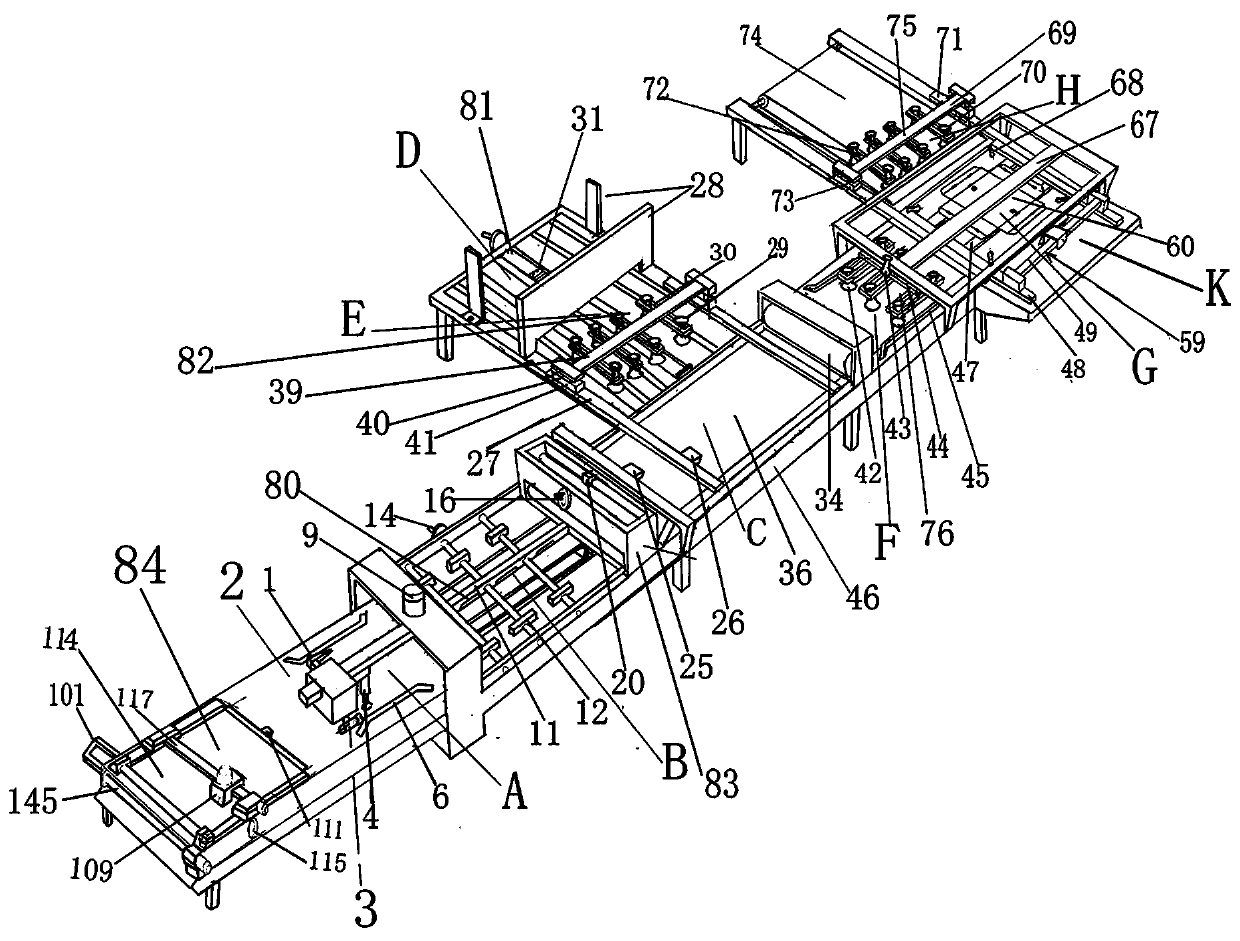

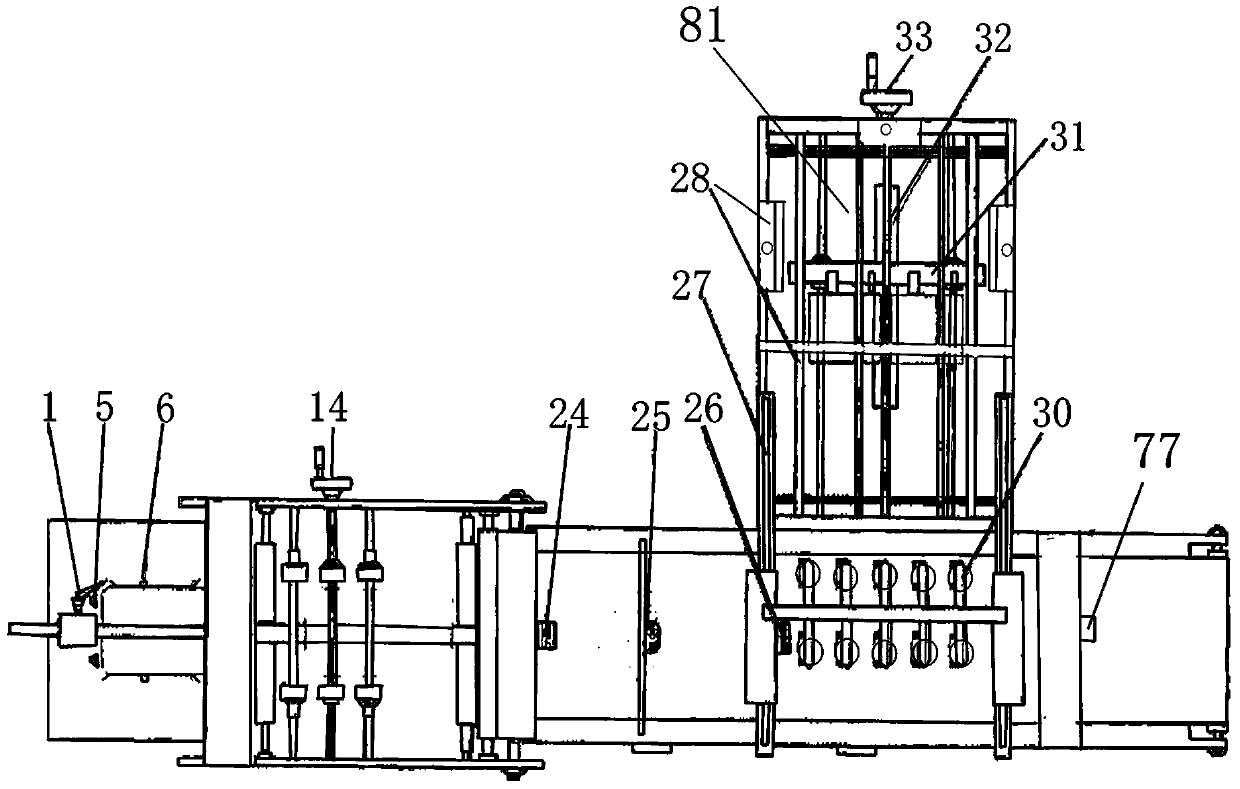

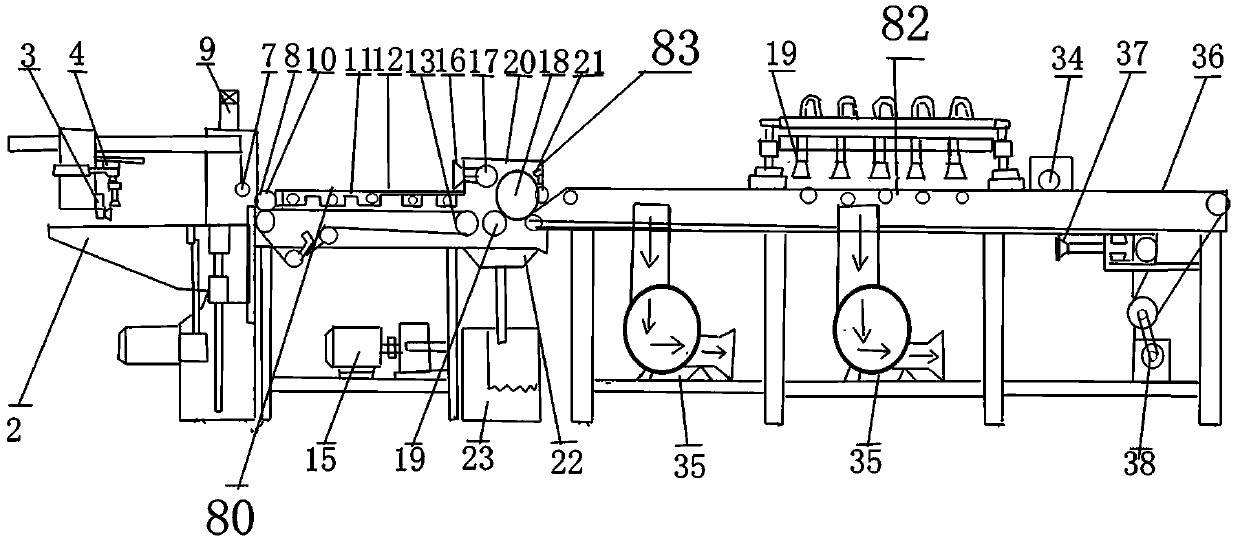

[0020] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, the present invention is made up of cutting device, gluing device, drawing board positioning device and hemming folding device, and cutting device, gluing device, drawing board positioning device and hemming folding device are connected as a whole by frame 46: please refer to figure 1 , Figure 7 with Figure 8 As shown, the cutting device 84 is composed of the man-machine automation programming control device 101, the laser cutting head 109, the conveyor belt device 114, the first guide rail assembly 117, the suction system 115 and the dotted line cutting device 145, and the man-machine automation programming Control device 101, laser cutting head 109, conveyor belt device 114, suction system 115, dotted line cutting device 145 and first guide rail assembly 117 are all arranged on the frame 46, as Figure 7 As shown, the laser cutting head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com