Hub motor driving device

A driving device and wheel hub motor technology, applied in the direction of power device, control device, motion deposition, etc., can solve the problems of regular maintenance, high failure rate, complex structure, etc., and achieve the goals of reducing mechanical wear, improving working performance and reducing energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

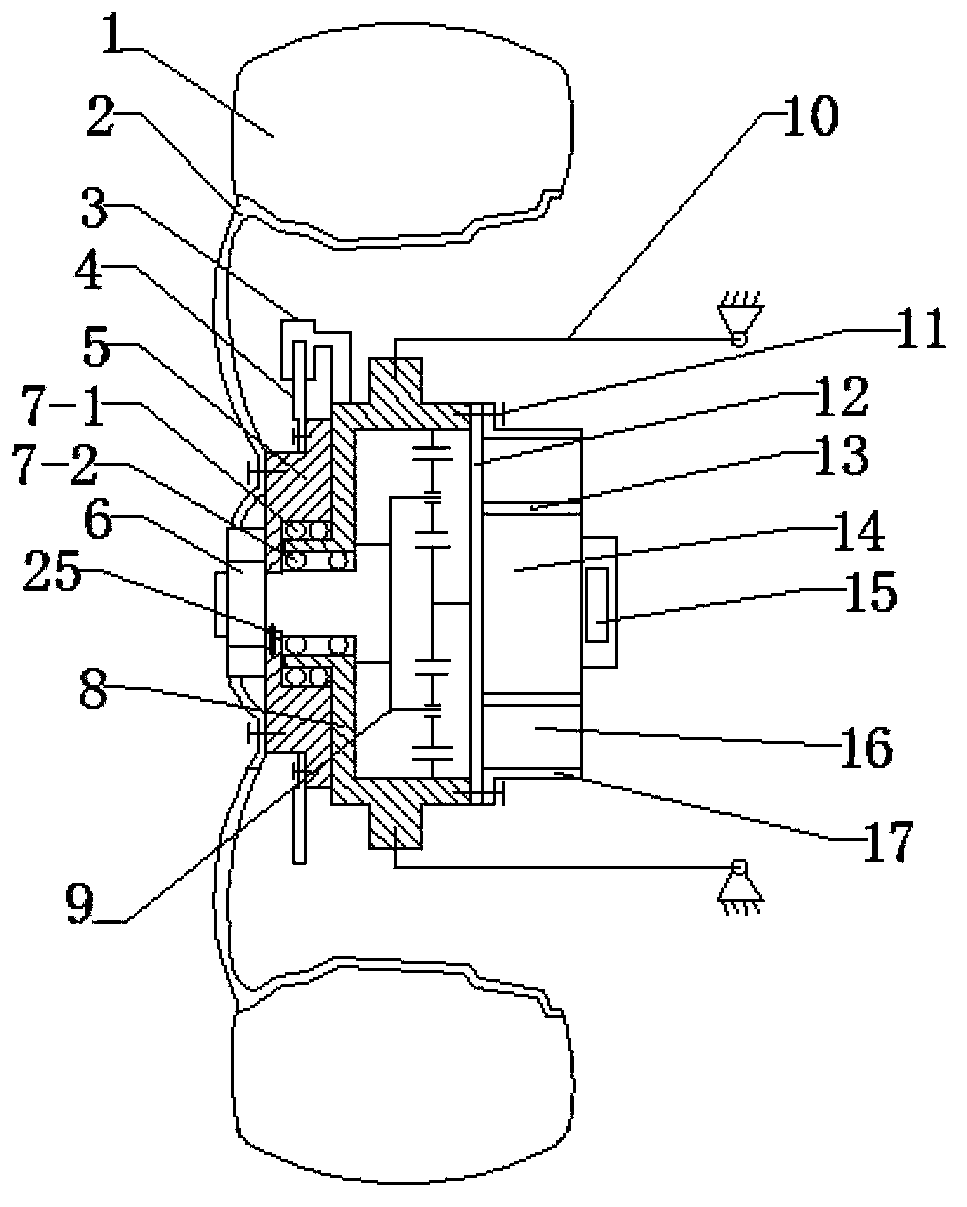

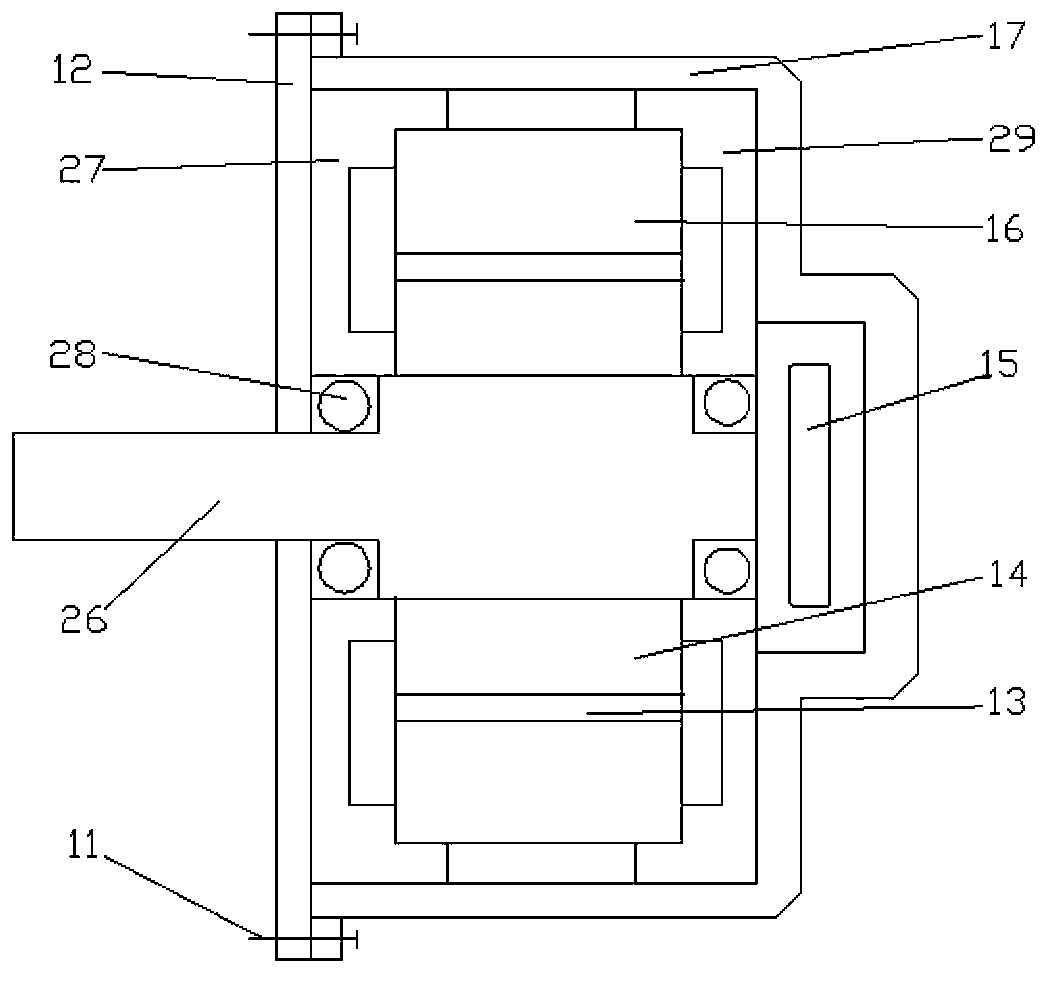

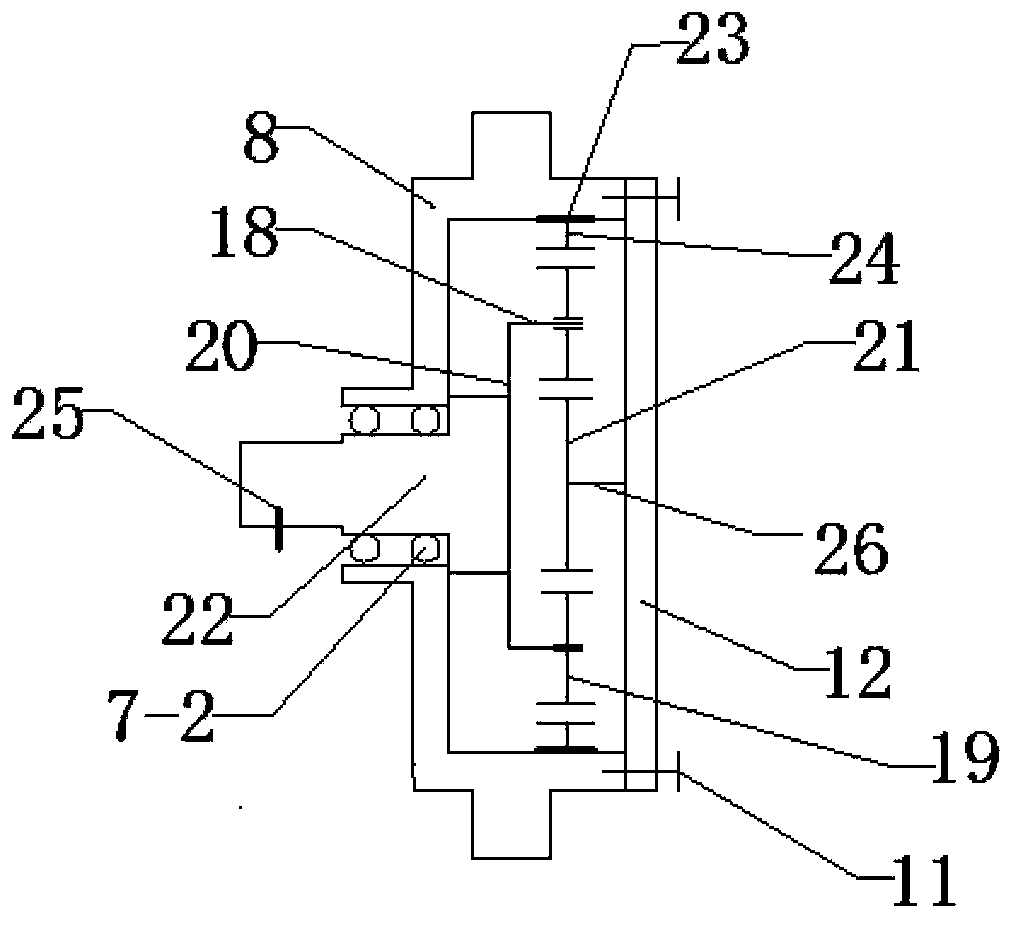

[0022] Such as Figure 1 to Figure 3 As shown, the hub motor driving device is a high-speed inner rotor hub motor driving device, which includes a transmission hub, a reducer and a drive motor, the transmission hub 5 is installed on the hub 2, and the reducer housing 8 of the reducer is installed on the suspension of the vehicle 10, the driving motor is installed on the reducer housing 8, the driving motor is connected and sealed by the motor housing 17 and the motor front end cover 12 through bolts 11, and the stator 16 and the rotor 14 are mainly arranged inside the motor housing 17, wherein the rotor 14 and the stator 16 are fixed by the fixed frame I 27 and the fixed frame II 29 arranged on the left and right, and the motor shaft 26 is installed at the center of the rotor, and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com